Revolutionize Your Rebar Bending with Automatic Machines

A Rebar Bending machine bends steel bars or any heavy metal bars. They are most popular in construction projects as they allow workers to bend heavy steel bars at certain angles.

It adds excellent stability and strength to the metals and hence makes the underlying structure of the building stronger.

In the following text, we will discuss the different types of automatic rebar bending machines used in construction, the critical features of the engine, the advantages, and the way to appoint a suitable machine for your needs.

Contents

Types of Automatic Rebar Bending Machines

There are 3 main types of rebar bending machines:

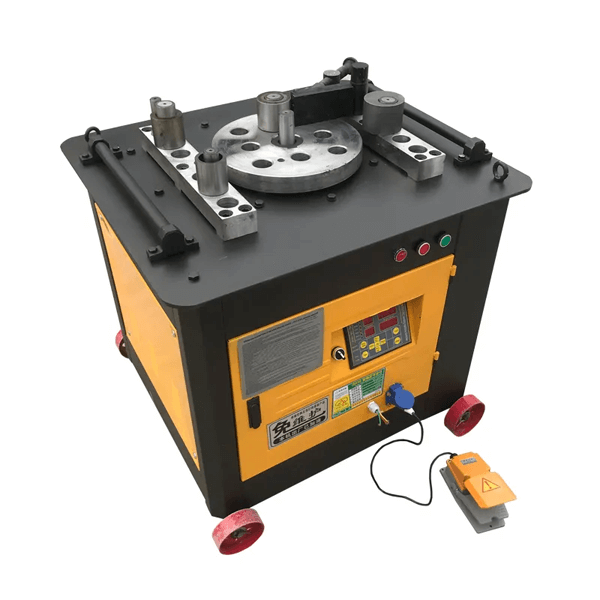

Electric Rebar Bending Machine

This type of machine can bend steel bars into various angles and arcs. Designed scientifically, it has a compact structure that is electrically powered. It makes the construction process swift.

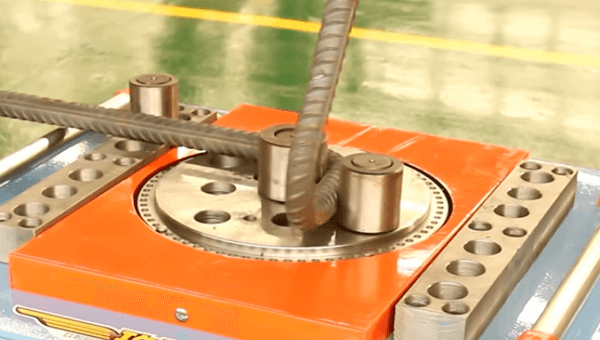

Pin indexing

It works in two phases. There is pin indexing, which uses three pieces, each at a different angle, such as 90 degrees and 135 degrees, and the third is placed for the STOP command.

Bending robot

The second part is the bending robot. Its purpose is to assemble a bend on a piece using a bending tool during a rotating motion

Hydraulic Rebar Bending Machine

The hydraulic motor creates a pressure sequence which is the principle of this machine. It is used to pump hydraulic fluid, which bends the rebar. It is equipped with dies to proceed with two things, the bending of rigid metal rebars and a clamping cylinder to prevent the line from slipping due to the pressure of the motor.

Bending only

Small or large-diameter rebars are bent with considerable force. The lines are bent accurately with great precision.

A mandrel, a shaft to which work is fixed while being turned, is fitted on the rebar and fastened by clamping it to perform the bending operation. The bending angle is chosen, and the machine bends the line accurately.

With cutting

The Rebar Cutter Bender combines two functions, bending and cutting. Flipping the lever will help select either the cutting or bending option.

CNC Rebar Bending Machine

It is a computerized control automatic stirrup bending machine. It is fed with a brilliant program integrating control and feeding.

It performs many tasks, such as scaling, straightening, bending, and cutting metal rebars.

Rebar bending

The CNC Rebar bending machine comes as a single, easily portable unit. It has a computer panel installed on one side. It is similar to a semi-automatic rebar bending machine except that the bending heads are installed on a rotating disc onto which bars can be inserted and turned to specific angles as the disc rotates.

Stirrup making

It is also particular regarding accurate measurements of the stirrup. The productivity is twice as effective in bending rebars and making many stirrups simultaneously.

Key Features of Automatic Rebar Bending Machines

- High Efficiency: Using an automatic rebar bending machine has reduced the number of workers required to use a manual one. This way, the workers can spend time and energy on the other aspects of construction. Using an automatic rebar bending machine has caused an increase in the workforce in a small amount of time.

- Precision Bending: The automatic machines use precise methods to accurately cut and bend the rods into the required angles. This results in the better usage of the materials and the replica of the blueprints of the building, as the measurements are accurate.

- Cost-effectiveness: Bearing the cost of the number of workers required to bend the rods manually can leave a massive dent in the construction company’s finances. The optimal solution would be to invest in an automatic rebar bending machine. Investing in an excellent automatic rebar bending machine can save many costs for building companies.

- User-friendly Operation: Workers are trained once or twice on how to operate the machine, all the buttons are labeled, and it is a straightforward and effortless process. One worker is required to bend an endless amount of rods. This way, only one worker is occupied for a short period, and the rest can contribute to other forms of work.

Advantages of Using Automatic Rebar Bending Machines

- Time-saving: Increasing the speed of the work results in cutting down the time taken to bend the rods manually. Allows the workers to do multiple jobs in one day and complete more work simultaneously.

- Improved Safety: Automatic bending machines reduce the chances of work-related accidents often encountered in manual bending. The automatic models have safety options and have been tested frequently to ensure maximal safety. As it is highly portable and can be transported anywhere, it is quickly brought near the place requiring the bent rods and taken back to a safe place once construction begins. It also ensures that the machine is not in the way of the workers; hence, it is not a health risk.

- Consistent Quality: This machine is manufactured with mechanical and electrical components that perform the bending process in a highly accurate manner. The bending equipment achieves skillful bending angles and arcs. It can turn in a variety of arches ranging from 0 to 180 degrees. The finishing quality will be persistent as it is not manhandled but done through machinery.

- Reduced Labor Costs: It is a worthy investment as it cuts down on the work time and force at the construction site.

How to Choose the Right Automatic Rebar Bending Machine

- Understanding Your Needs: Depending on the diameter of the rods you use in your line of work, your company can purchase different automatic rebar bending machines. To understand which machine is suitable, we need to know the model name, such as GW40. The number stands for the maximum diameter of the rod that it can bend, so 40mm in this case. If you have to bend various rods of different diameters, then be vigilant in choosing the largest diameter and hence the corresponding number when it comes to the model number.

- Quality and Durability: The electric rebar bending machine has a compact structure which causes it to have strong durability. It is a safe option in concrete-reinforced construction jobs.

- Compatibility with Existing Equipment: Depending on the skillfulness of the workers on the job, one can choose the suitable automatic rebar bending machine. If the workers are relatively new and need practice, a more advanced CNC rebar bending machine would be sufficient as it is entirely automated.

- Price and Maintenance Costs: Depending on the type of automatic rebar bending machine you opt for, the pricing and maintenance cost will be accordingly. The CNC rebar bending machine costs the most since it’s wholly computerized and requires little to no assistance.

Conclusion

Automatic rebar bending machines are the future of the construction industry. It is machinery worth investing in for the future. It allows the workers to be highly efficient and work within a period. It is user-friendly and results in defined materials. Whether it is electric, using the help of hydraulic fluid, or completely computerized, no amount of manual bending can compare to the results of this machinery.

Leave A Comment