Can You Cut Concrete with a Circular Saw? Yes, Here’s How

Concrete cutting is a job that belongs to a set of DIY jobs. They frequently meet at homes when it comes to laying patios, making pavers, or building walls. The question is whether a circular saw, made of wood, can also be used to work on concrete.

It depends; yes, just under some conditions. A circular saw can be used to cut concrete with the right blade, technique and safety precautions.

This guide shall assist you in knowing what tools and equipment are needed. The effective usage of such tools and equipment shall be discussed. Moreover, it will cover procedures for producing clean cuts

Contents

Can a Circular Saw Cut Concrete

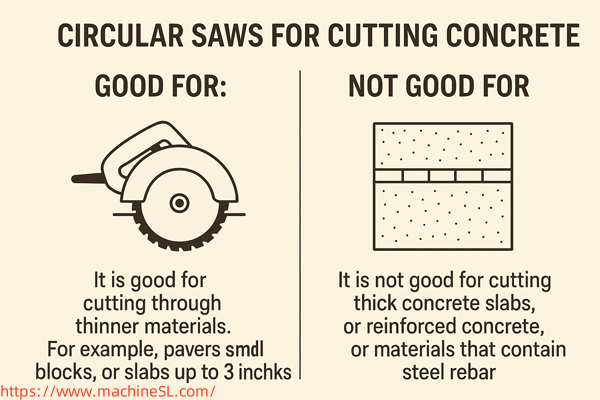

Generally, Circular saws are not made to cut concrete. With the diamond blade, they can handle concrete for small and medium-sized jobs. Concrete saws are made for the purpose of cutting concrete.

They can handle more tedious tasks, chopping through highly dense or reinforced concrete. A circular saw is suitable for cutting thinner concrete materials,e.g., pavers or small blocks. It will struggle with cutting 3 inches of thick concrete or reinforced with steel rebar.

Quick Takeaway:

- Good for: It is good for cutting through thinner materials. For example, pavers, small concrete blocks, or slabs up to 3 inches thick.

- Not Good for: It is not good for cutting thick concrete slabs or reinforced concrete, or materials that contain steel rebar. These materials require a more powerful and specialized concrete saw.

What You Need Before You Start

Essential Tools & Materials

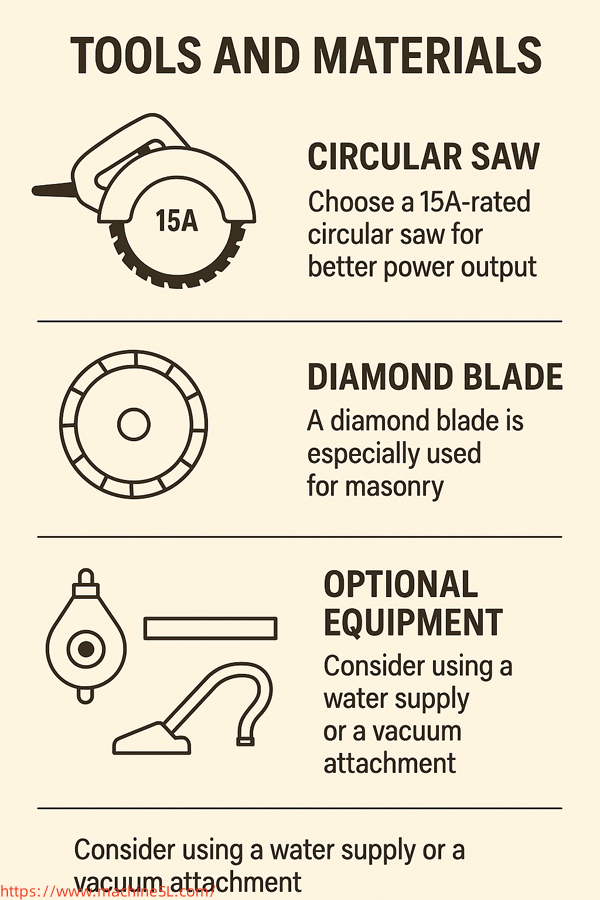

While using a circular saw, proper tools adn materials are required. This will lead to doing the job safely and efficiently. These include:

- Circular Saw: Choose a 15A-rated circular saw for better power output. The greater amperage guarantees tackling the task without stressing the motor.

- Diamond Blade: A diamond blade is especially used for masonry. This plays an essential role in the cutting of concrete. The blade you select will be dependent on what you are cutting, and the level of good/finish you want.

- Depending on the type of concrete and cut, you will require one segmented, turbo or continuous rim blade.

- Chalk Line or Straight Edge: It is applied in the marking of straight cut lines. Such lines make your cuts precise and accurate.

- Optional Equipment: Consider using a water supply to wet cut or a vacuum attachment. It will make your job easier as it helps control dust during dry cutting.

Personal Protective Equipment (PPE)

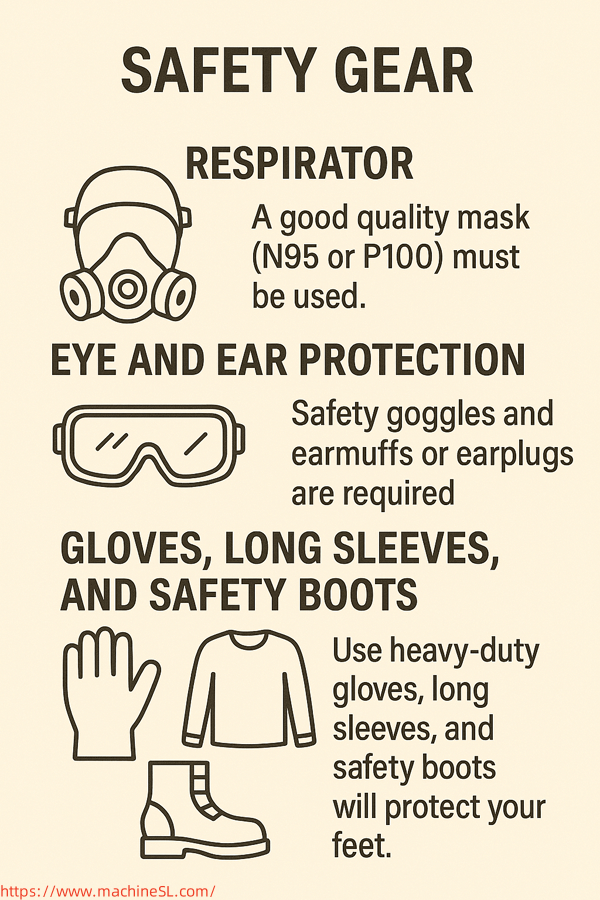

Dust and debris are produced during the process of concrete cutting. Thus, while doing so, safety should be prioritized. The proper personal protective gear (PPE) will aid in minimizing your injury. It will also ensure a safe work environment. The following PPE should be worn:

- Respirator: A good quality mask (N95 or P100) must be used. It guards against inhaling dust into your lungs. Wet cutting reduces the amount of dust, but partial respiratory protection remains.

- Protection of the eyes and ears: Safety goggles are required so that your eyes are safe. They are supposed to wear earmuffs or earplugs, which are ear protection. There will be a need to prevent the deafening sound that is involved in the process of cutting concrete.

- Gloves, Long Sleeves, and Safety Boots: Use heavy-duty gloves. These will assist in communicating the sharp edges to a hand. Your sleeves should be kept longer, suggesting protection for your arms. Safety boots will protect your feet.

Blade Types: Which One Should You Use

Selecting a proper blade that suits the cutting is important for a clean and efficient cut. The diamond blades are of three major types. These are designed for different materials and cutting conditions.

| Blade Type | Best For | Pros | Cons |

| Segmented Diamond | Blocks, slabs | Fast cutting speed and effective dust clearing. Ideal for cutting through thicker concrete. | Results in a rough finish, less clean. |

| Turbo Diamond | Slabs, pavers | Provides smooth and fast cuts while reducing wear on the blade. Ideal for cuts requiring speed and efficiency. | Generates more dust than other types. |

| Continuous Rim | Pavers, tiles | Delivers a clean and smooth finish. Good for precision cutting. | Slower cutting speed; requires water for cooling. |

How to Choose

- Segmented Diamond blade: It’s the best option when working with thicker concrete. It is also suitable for fast, rough and speedy cuts. However, the finish quality is a little less concern.

- Turbo Diamond blade: This type provides a faster and smoother cut and cleaner results compared to segmented blades. However, it generates more dust.

- Continuous Rim blade: It is ideal for cuts where cleanliness and precision are paramount. It provides the cleanest cut but requires water to prevent overheating.

Step-By-Step: How to Cut Concrete with a Circular Saw

For a safe and smooth concrete cutting operation, one must follow the steps as below:

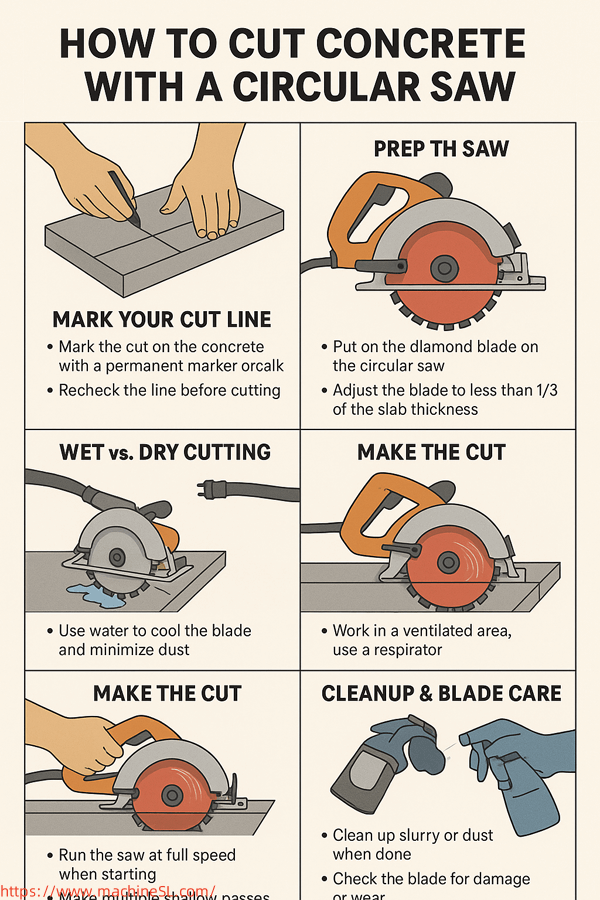

Step 1: Mark Your Cut Line

- Mark the cut on the concrete with either a permanent marker or chalk line. The thing is to check your measurements twice. Ensure that the lines are straight so that the results do not go wrong during the cutting procedure.

- Recheck the line you are going to cut on before cutting.

Step 2: Prep the Saw

- Put on the diamond blade on the circular saw. The blade you will use should fit firmly on the arbor of the saw. It avoids the wobbling and slipping during the cutting.

- Adjust the depth of the blade to less than 1/3 the thickness of the concrete slab. This will assist in ensuring that the saw is efficient. It does not strain the motor, and wear and tear can result.

Step 3: Wet vs Dry Cutting

- Wet Cutting:

- Wet cutting is created with the help of water, which cools the blade and would minimize dust. In order to wet cut, a hose or a spray bottle will be required to control the water supply.

- To be safe, be sure that anything beyond that plug-in is an extension cord with a GFCI rating.

- Dry Cutting:

- Dry cutting can be carried out instead of wet cutting. Nonetheless, you should carry this out in ventilated premises. Always use a respirator to prevent the dust from concrete.

- You can also consider a vacuum attachment to minimise dust around the workplace.

Step 4: Make the Cut

- When it comes into contact with the saw, turn it on full speed in order to cut adequately.

- Take care to keep the cutting power. Looking at deeper cuts with many shallow passes.

- This alleviates the chance of overheating the blade and leaving a cleaner and better-controlled cut.

- Let the saw work out, not push it through the wood. Making the saw do common blades and motors tends to cause their untimely wear out.

Step 5: Cleanup & Blade Care

- Before each cut beside the other, cool down the blade and then proceed with another cut. This will improve the life of the blade and will prevent overheating.

- In case of wet cutting, clean any slurry. However, during dry cutting, dust is removed by washing. Immediate cleaning after the cut will keep the workplace in order. It ensures that your gadgets (tools) are in good shape.

- After using it, make sure the blade is in good condition and there is no damage to the blade. Change the blade when it becomes worn out, which can manifest itself in dullness or cracks.

What a Circular Saw Can and Can’t Handle

It is essential to understand the materials that a circular saw can effectively cut. Here’s a breakdown:

| Material Type | Suitability | Notes |

| Concrete Pavers | ✅ Excellent | Pavers are relatively thin and easy to cut with a circular saw. |

| Concrete Blocks | ✅ Good | Circular saws can cut concrete blocks, but relief cuts may be necessary for a cleaner finish. |

| Concrete Slabs (≤3”) | ⚠️ Feasible | Circular saws can handle slabs up to 3 inches thick, but multiple passes will be required. |

| Reinforced Concrete | ❌ Not Recommended | Steel rebar will quickly damage a circular saw blade. Use a concrete saw for reinforced concrete. |

Steel rebar will quickly damage a circular saw blade. Use a concrete saw for reinforced concrete.

Tips from the Pros

- Always go shallow and let the saw rest: This reduces the wear on the saw and prevents overheating.

- Wet cutting saves blades and lungs: Always prefer wet cutting if you have access to water. It reduces dust and prolongs the blade’s lifespan.

- Mark both sides of the slab for cleaner results: If possible, mark both sides of the concrete slab. It will guide a more precise and straighter cut.

- Rent a walk-behind saw for thicker slabs: For slabs thicker than 4 inches, a walk-behind saw is a better tool to use. It is for better efficiency and results.

Common Mistakes to Avoid

- Wood blades: These are not concrete-recommended and may crack or destroy your saw.

- Overstraining the saw: Overworking the saw may break your motor and saw blade.

- Skipping PPE: Never compromise on safety. PPE is essential to protect yourself from concrete dust, debris, and noise.

- Trying to cut all in one pass: Trying to cut through thick concrete all at once is inefficient. It can also damage your equipment. Always make multiple shallow passes.

- Forgetting dust control: Concrete dust is hazardous. Always have dust control measures in place, especially when dry cutting.

When to Use a Concrete Saw Instead

A concrete saw is more suitable for larger or more complex jobs:

- Slabs > 4 inches deep: Concrete saws are designed for cutting through thick concrete. They can handle deeper cuts with ease.

- Structural Cuts: Concrete saws provide precision and efficiency for structural applications.

- Large Driveways or Trenching: A concrete saw will be faster and more efficient for large projects.

- Time Efficiency or Perfect Finish: Concrete saws are ideal for a perfect cut with minimal effort.

Summary: Is It Worth It

A circular saw can work well for small, non-structural concrete cutting tasks. For example, pavers or thin slabs. However, for more demanding tasks, a specialized concrete saw is necessary. It may be cutting thick slabs or reinforced concrete.

| Scenario | Circular Saw | Alternative |

| Patio Pavers | ✅ Yes | – |

| 4” Slab | ⚠ Maybe | Walk-behind saw |

| Wall with Rebar | ❌ No | Concrete saw or demo saw |

FAQs

Q1: Can any circular saw cut concrete?

Only if it’s equipped with a masonry diamond blade.

Q2: Is it safe to wet cut with a circular saw?

Yes, but ensure water control and use a GFCI outlet.

Q3: Will cutting concrete ruin my saw?

Overuse or dry cutting can reduce the saw’s lifespan.

Q4: How deep can a 7” blade cut?

Usually, a 7″ blade is capable of cutting 2.25 inches deep.

Q5: Can I cut reinforced concrete with a circular saw?

It’s not recommended—use a concrete saw for reinforced concrete.

Alternatives for Concrete Cutting

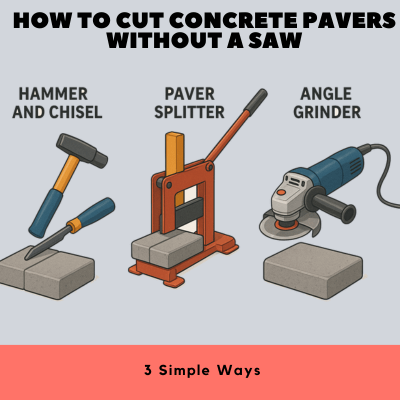

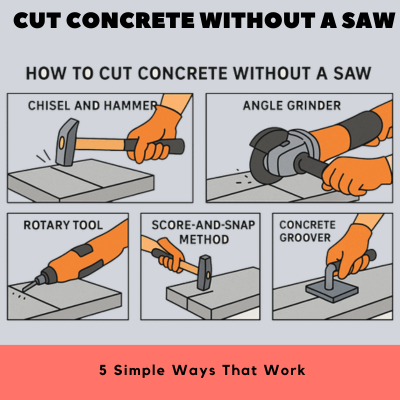

If a circular saw doesn’t meet your needs, try these alternatives:

- Angle Grinder: For smaller jobs.

- Reciprocating Saw with Carbide Grit Blade: For tough cuts.

- Hammer and Chisel: Basic, manual cutting.

Leave A Comment