11 Different Types Soil Compaction Equipment: How to Select The Correct One

Compaction is the job, which is often required at majority of the construction projects. The process of compaction involves removing any air entertainment in soil to make to it dense. This will result in better bearing capacity of the soil for supporting heavier loads on top of it without any failure.

In this article, we will explore different types of compaction equipment’s and we will guide you to select the right one for your job.

Contents

Types of Soil Compaction Equipment

The compaction equipment for soil can be categorized in two type based on their mass.

- light soil compaction equipment

- heavy soil compaction equipment

We will explore further each of this type of equipment and the type of machines which fall under these two categories in following sections.

Light Soil Compaction Equipment

These types of equipment are used particularly for compacting small areas, which require less compaction effort (force). Following equipment fall under the category of Light compaction equipment.

- Rammers

- vibratory tampers

- vibratory plate compactors

Rammers

Rammer are machine powered and hand steered small machines used for compacting small areas by providing an impact to the soil. Rammers are lighter in weight so that they can be handled by single person.

The base size of the rammers is usually smaller of area ranging from 15 x 15 cm2 to 20 x 20 cm2. Usually, their weights are in the range of 30 kgs to 10 tons.

In case of rock compaction, these rammers can weigh up to two or three tons and can fall freely from the heights of 1 or 2 m to crush the rock underneath them.

Rammers are particularly suitable for compacting cohesive soils like clays located in small areas like trenches and building foundations.

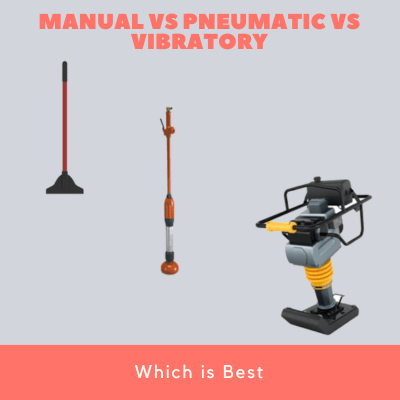

Vibratory Tampers

The base plate installed on vibratory tampers is spring activated by an alternative mechanism driven by a motor.

Vibratory tampers are also ideal to be used in smaller areas in confined zones. They can even be used to compact all types of soils using the vibrations.

They are usually manually guided like rammers and weigh between 50 and 100 kgs.

Vibratory Plate Compactors

Vibratory plate compactors are particularly used on course soils like sand containing four to eight percent fine particles like clay.

In contrast to rammers, which compact soil by producing an impact, vibratory plate compactors compact the soil by producing vibrations.

Weight of these machines can range between 100 kgs and 2 tons. The plate areas are also bigger in contrast to rammers, with areas ranging from 0.16 to 1.6 square meters.

Heavy Soil Compaction Equipment

These types of equipment are used particularly for compacting larger areas with different types of soils, which may require less or large compaction effort (force).

Heavy compaction equipment is selected based on the amount of moisture content in soil and type of soil.

Following equipment fall under the category of Heavy compaction equipment.

- Smooth wheels rollers

- Sheep foot rollers

- Elephant foot rollers

- Pneumatic tired rollers

- Wobble wheel roller

- Impact roller

- Grid rolls

- Pad foot/ presser rollers

Smooth Wheel Rollers

These types of rollers apply static compression on the soil underneath their rolls. These machines are triple wheeled vehicles. Front wheel is made of one large drum, while on the rear side there are two large drum wheels.

The static compression is applied through these drum shaped wheels. These machines are used with granular soils. Most commonly they are used in compacting the base course of roads and paving highways and airfields.

These machines are propelled by a diesel engine. The weights of the drum wheels can be altered by adding ballast or other heavy materials inside the drums.

Their weight can range from 10 to 200 kg per drum. As a result, the pressure exerted by them is in the order of 300 N, which of course can be varied by adding more ballast into the drums.

Sheep Foot Rollers

The sheep foot roller is also a vehicle similar to smooth wheel rollers. However, in contrast to a smooth drum used in smooth wheel rollers, these machines have a sheep’s foot or tamping roller in front. While on the rear side, they have tyres.

Sheep’s foot or tamping roller consists of a hollow steel cylindrical drum made with steel projections or feet extending in a radial direction on front. These projections of feet are extended outward from the cylinder surface.

The dimension of the roller can be varied to get different soil compaction capacities. These dimensions include the diameter and width of the drum and length and shape of the feet of the rollers. Usually, the feet are 15 to 20 cm long and placed in staggered row around the drum. This allows to obtain a contact of about two tamping feet per square foot of tamped area. The weight of the drums can also be varied in a way similar to smooth wheel rollers.

Sheep foot rollers are particularly suitable for cohesive soils. This is due to smaller width of loaded areas under their feet. Sometimes sheep foot rollers are also employed in pre compaction phase on the areas with slabby soil fragments of rock soils. The break down these soft rock fragments. They are also used to pulverize hard dry soil and can also help in mixing of soils.

Sometimes, these rollers are also towed by a tractor. This also allows a compaction through vibration. Especially in sandy soils, mixing large quantities of water and using a towing tractor will couple the benefits of vibrations to achieve much better compaction.

Elephant Foot Roller

A sheep foot roller is sometimes also termed as elephant foot roller, if the some of the feet are removed from the drum and are replaced with 20 to 25 cm wide flat plated welded on the remaining feet of the drum.

Elephant rollers are useful for silty soils of low cohesion. This is due to the increased widths of the loaded area, that produces greater confinement.

Pneumatic Tired Rollers

Pneumatic tired rollers consist of a platform mounted on two axles. The rear axle has one more wheel compare with the front axle. The total width of all the inflated tyres is approximately equal to 80% width of the rollers.

They are not commonly used on soils. Instead, there best use can be found in the area where the surface to be rolled is not rough or steep like the asphalt of the roads.

The pneumatic tired roller is ideal for compaction of cohesion-less or slightly cohesive soils. These soils include gravels, sands, clayey sands, silty sands and even sandy clays. The pressure applied by them is distributed over relatively larger areas, which prevents the soil from collapsing.

Wobble Wheel Roller

Wobble wheel roller are similar to pneumatic tired rollers except that their wheels are mounted at a slight angle with respect to their axle. This also allows to achieve slight kneading action.

Impact Roller

In impact rollers, a tractor pulls a prism shaped mass, made of steel or concrete. As a result of rotation of prism shaped mass, an impact is generated, which transfers sufficient energy to achieve medium compaction to a depth of several meters.

This type of roller can be used for granular soils including gravels and rock fills.

Grid Rollers

These rollers are made of cylindrical surfaces of steel grid formed by a network of steel bars. The grid is made of square holes. The weight of the grid can be achieved by adding ballast into the cylinder. Usually, their weight ranges from 5.5 tons to 15 tons with ballast added.

Grid rollers are used for compacting weathered rocks and thick soils. On the other hand, they are not suitable clayey soils, silty soils and uniform soils. They are mainly used in subbase construction in roads projects.

Pad Foot/Slash Presser Rollers

The roller is similar to sheep foot roller. However, they have lugs on their cylinders, which have larger area than the feet of sheep foot rollers.

They are also sometimes termed as tamping rollers having static weight in the range of 15 to 40 tons. They can achieve more degree of compaction than sheep foot rollers. They also operate on high speeds and can break down large lumps of soil. They are best suitable for compacting cohesive soils.

Selection Guide of The Equipment

Scale of The Construction Project

- Large scale projects involving larger areas to be compacted e.g., road projects, embankments, dams –> Heavy soil compaction equipment

- Small scale projects involving smaller, confined areas to be compacted e.g., trenches, building foundations, farms, fencing –> Small soil compaction equipment

Type of Compacted Material

Cohesive soils

Clays:

- Rammers

- Vibratory plate compactors

- Sheep foot rollers

- Wobble wheel roller

- Pneumatic tired rollers

- Pad foot/slash presser rollers

Silty soils:

- Elephant foot roller

- Grid rollers

Granular soils

Sand:

- Vibratory tamper

- Smooth wheel rollers

Rocks:

- Vibratory tamper

- Sheep foot rollers

- Impact rollers

- Grid rollers

Asphalt surface

- Pneumatic tired rollers

Different Types of On Field Soil Compaction Test

Soil compactions test at construction sites can be monitored through following tests

- Standard proctor test

- Sand cone test

- Rubber balloon test

- Nuclear Density Test

Buying or Renting Soil Compaction Equipment

Buying or renting equipment depend on certain factors. They include:

- Cost of equipment

- Maintenance cost of equipment

- Storage cost

- Insurance premiums

- Duration of the project

- Rent vs cost comparison of equipment.

Usually, contractor have to keep in mind all these factors before choosing between renting or buying the right type of compaction equipment

Very nice machine I need rammer

Thank you Dare,let’s keep in touch by email

Thank you

thanks

very clear and good article easy to understand. Thank you

thanks