8 Types of Construction Piles and Pile Cutting Guide [Tips]

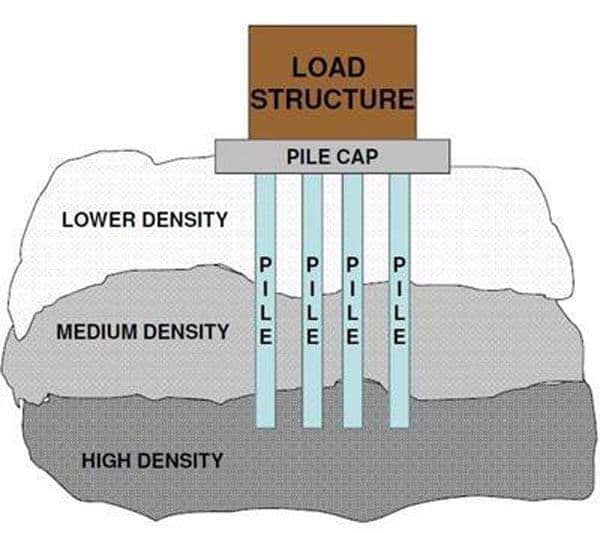

Pile foundation, as we know, is a type of deep foundation that transfers load from superstructure to deep soil which has high bearing capacity.

It is used in places where the superficial soil layer cannot provide support to the structure due to poor soil quality. This can occur due to high groundwater table, soil at shallow depth is compressible or due to the presence of drainage system nearby.

Piles are long, slender columnar elements that carry the loads to deeper levels through either skin friction of end load bearings. A typical pile foundation has a length greater than three times its breadth.

Contents

Function Types

On the basis of their function, ‘pile foundation’ can be divided as –

Sheet Piles

Sheet piles provide lateral support as they resist pressure from loose soil, flow of water, etc. They are not used to provide vertical support to the structure thus making them ideal to be used in cofferdams, trench sheeting, and for shore protection.

Load Bearing Piles

Load bearing piles are used to transfer loads from poor soil at the top to the bottom layers of high bearing capacity soils.

Load Transfer Types

Depending on the mechanism of load transfer it can be further divided as –

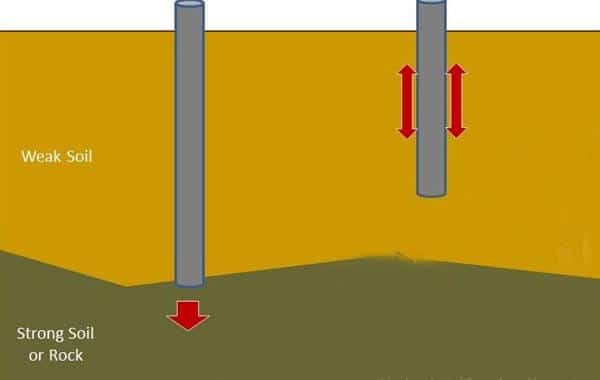

End Bearing Piles

In this type of foundation, piles rest on a strong layer of soil or rock at the bottom and transfer the structural loads through the lower tip. The piles act as columns and safely transfer the loads to lower layers.

Friction Piles

As the names suggest, friction piles transfer the load through friction to the surrounding strata. The entire surface of piles works to transfer the loads from the superstructure to the soil.

Soil Compactor Piles

These are closely compacted pile columns erected in the soil to increase the bearing capacity by compaction. Depending on the construction method these are further classified as displacement piles; where the soil is removed, and non-displacement piles, where the soil remains intact.

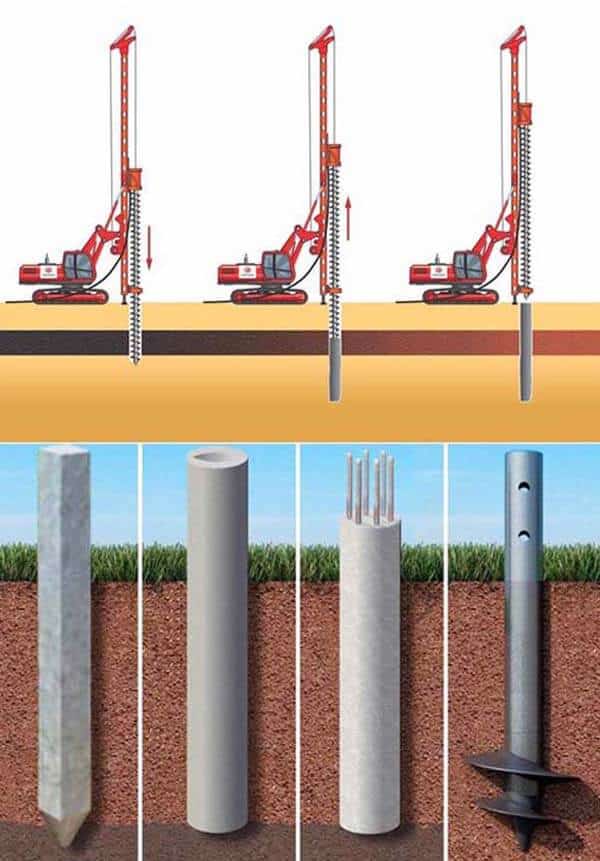

On the basis of materials ‘pile foundations’ can be classified as timber, steel, reinforced concrete, and composite.

Timber Piles

Timber piles are placed under the water level and last approximately 30 years. They are usually rectangular or circular in shape.

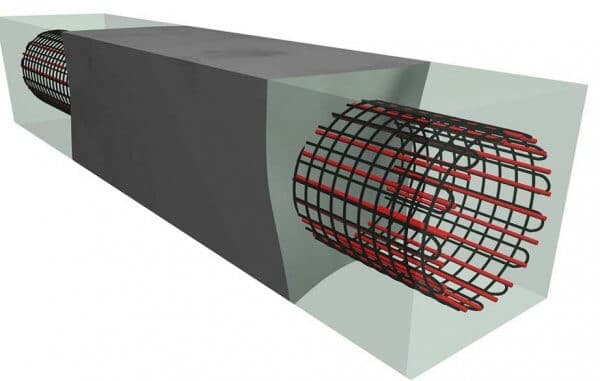

Reinforced Concrete Piles

Pre-cast concrete piles can be rectangular or circular in shape but they are reinforced with steel bars to prevent breakage during transportation from casting till site location of foundation.

Cast-in-situ piles are constructed by boring of soil to the desired depth and filling it with freshly mixed concrete. This can either be done by driving a metallic shell to the ground which is later filled with concrete and shell remains in its place. Or the concrete is poured and the shell is removed simultaneously.

Steel Piles

Steel piles are shaped as I-section or hollow pipes and are filled with concrete.

Pile Cut-off Level

Pile cut-off level is the actual level at which the concrete piles are placed underneath the pier so they can retain the same level. Pile cut-off level is provided in the specifications drawings, normally around 75mm. The concrete is cut-off at a certain height below, to allow the steel bars to go up till the pier to assure the bond is strong between them.

Another condition is, foundation piles for building, always you need to cut them in a same certain level, normally around 10mm to foundation ground

Tips to Cut

Cropping or trimming process is performed to achieve the minimum cut-off level and can be done using various instruments and machinery.

When the piles are cast in dry holes with a temporary casing, pile heads are supposed to be cast longer than the specified cut-off so that once it is cut, a stronger bond can be formed between piles and pier.

When the piles are cast underwater a different approach is considered known as the ‘Tremie Method’.

In this method the concrete piles are cast using a tremie pipe which is dropped under the water level and the concrete is filled with pressure. Once the slurry and other raw concrete materials are out, the concrete forms a bond. Pile cut-off can be located either over or under the ground. When the concrete is over the ground, it will run over from the pile head on execution and because of the tremie method the upper section is comprised of weaker concrete which should then be trimmed.

When the pile is under the ground, the concrete level should ideally be made 1m longer to provide length to cut-off the weak concrete.

How to Select a Pile Cutting Machine

In recent times, the availability of concrete pile cutting machines has increased extremely.

Technology has played a major role in improvising cutting techniques. From jackhammers to advanced concrete choppers, the change has been tremendous.

The market is now filled with an array of options that cater to the needs of different types, sizes, and materials of pile foundation.

There is no ‘single pile cutter that fits all’. Hence, it is mandatory to invest in the right machine.

Tips to Buy a Cutting Machine

Before buying a pile cutting machine following points must be considered –

1. Cast-in-situ concrete piles can be challenging, especially with the strict site norms. It is advised to always check the reinforcement bar thickness and pile width before choosing the cutter. The right pile cutting machinery should have a specification of trimming your desired width.

2. In mega projects, thousands of piles are cast and required to cut timely and efficiently. Therefore, investing in a cutter that leaves a leading class finish, which is ready for final reduction to form level, is very important.

3. Pre-cast bars are usually cast in larger numbers and it becomes manually impossible to keep a check on every pile. The common mistake that buyers do is they invest in powerful machinery in order to perform tasks speedily which leads to damaged or broken bars. This increases the repair cost. It is suggested to invest in ‘softer’ cutters to avoid this loophole.

4. In the case of displacement piles the contaminated soil surrounds a pile column which makes it harder for the pile cutter to sit square. It struggles to penetrate the core and reinforcement cage. Extra research should be made for such projects to invest in cutters manufactured especially for such kinds of cases.

5. De-bonding of the reinforced bar should be adopted to increase the productivity of pile reduction.

6. Maintenance, downtime, and storage cost should be considered during budgeting before making an unnecessary purchase.

7. Product configuration for each pile cutter must be studied specifically to avoid further confusion and delays in the project.

Conclusion

No two pile foundation construction has the same requirements. Hence, it is hard to buy a pile cutter that best suits all the needs.

Refer to the above tips before investing in the right machinery and to get good results.

Regular Machines As Follows:(wait a little bit more seconds for loading GIFs)

Hi there! Oh wow, I found it really interesting when you mentioned that timber piles have an average lifespan of up to three decades. My cousin has been assigned to find some construction materials for his workplace. I’ll ask him to consider this option so he’ll make the right purchase later.

thanks

thanks

Oh, hello. I was thinking if I could share this article with my cousin’s neighbor so he could rely on a reputable contractor sometime later. He wishes to build a small guest cabin in his backyard since his newly-wedded wife has a large family. I like it when you told us that sheet piles can be considered laterally supportive.

Hi Sam, glad to hear it’s helpful for you

Yes sir..

Love love love the simple graphs… they help so much . a pic is worth a 1000 words. that first one with the screw…priceless!

I guess you can tell by the feedback, you got a 2nd talent in teaching..in case you want to skip the dirt and semi-retire while sharing the industry knowledge youve acquired. Keep it up!

Hi, glad to hear it’s helpful for you