What is an Earth Rammer and How to Use It Benefit You Much?

Do you know what an earth rammer is? How to use a suitable rammer tool for your project? In this article, we will help you know much better

Contents

What is an Earth Rammer

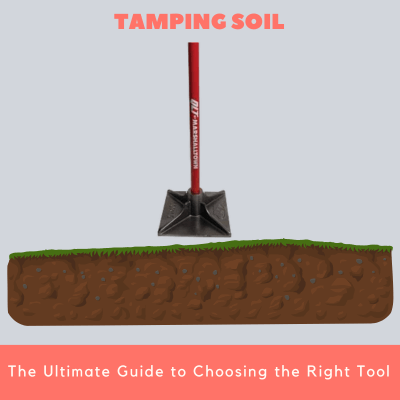

An earth rammer also termed as tamper is a hand tool used for compressing or compacting soil.

Soil is compacted or compressed to make it hard and of uniform level. Compaction is required to achieve an ideal groundwork for the construction projects that need a hard and flat surface. During compaction process, soil density is increased, and air is removed. This is usually done by mechanical means.

An earth rammer is one of that mechanical means, which creates a compacted surface of soil by pressing it repeatedly under its weight. Earth rammers are usually composed of two part: a handle and a head. The head of rammer should be heavy enough to compress the soil under its weight.

However, it should be light enough, so that the workers can lift it comfortably, if it is not powered by a machine.

Cast iron is usually used to made head. Heads have usually smooth surfaces. Different materials like wood and steel can be used to make handles.

Types of Projects

Where an earth rammer is most used:

- Construction site for compacting building foundation soil, laying turf, etc.

- Do It Yourself (DIY) projects like erecting a fence post or laying a patio

- Special uses like building an earth rammed wall.

Quality of Compaction

Where an earth rammer is most used:

Main factors affecting the quality of compaction using an earth rammer, there are three main factors that affect the quality of compaction using an earth rammer:

- the surface area of the rammer head

- the thickness or depth of earth surface to be rammed or compressed

- The force applied by the rammer either by the worker or the machine.

The above mentioned three factors are further discussed in following paragraph.

The surface area of the rammer head can be bigger, where the thickness or depth of fill is shallower and vice versa. Similarly, where the thickness or depth of fill is deeper, the force applied by rammer should be higher and vice versa.

What Soils Can It Be Used On

An earth rammer can be used on different types of soils. Some of the most common type of soils, where they can be used on a construction site are:

- Compact loose earth or soil.

- Fine gravel, clay, or sand.

Some Usual Types of Earth Rammer

Rammers can be classified into two categories based on the type of their operation.

- Man powered rammer

- Machine powered rammers

Following rammers can be grouped in these two categories.

Man Powered Rammers

- Square headed earth rammers

A square headed rammer is the most common type of rammer for projects that has a flat base. It is also known as a square headed earth rammer due to its flat, square-shaped head plate.

- Trenching tampers

A trenching tamper is a specially designed rammer for use in trenches. The head of a trenching hammer is a narrow head, which would be ideal for compacting base of a trench. Trenching tamper has a longer handle that makes it convenient for working at deeper levels.

- Fencing tampers

A fencing tamper is a specially designed rammer for use when putting up fence posts. It has a round head specialized for ramming earth inside the holes of fence posts.

Machine Powered Rammers

A mechanical earth rammer is powered by a machine that is fueled by oil or petrol. Sometimes it is also known as rammer compactor’ or a ‘vibratory rammer’.

Mechanical rammers, along with compacting the soil, also vibrate the individual soil particles and remove air particles. A mechanical rammer is maneuvered by hand and powered by either petrol or diesel engine.

Advantages

Machine Powered Rammer

- Compaction can be done at faster pace. Using a machine powered earth rammer is twice as fast as using a hand powered one. Therefore, it would also be more useful, when compacting a large area as it covers the surface quicker.

- Less human effort is required, therefore less man powered is required.

Man powered rammer

- Low cost in comparison to machine powered rammers.

- Useful in delicate locations. For trench tamping, man powered rammer is preferable over the mechanical one, because mechanical rammer can damage pipes, it encounters.

- It produces less noise that the machine powered one.

- Single person can easily handle it.

How to Make a Manual Earth Rammer/DIY

You can also make an earth rammer at home all by yourself in 3 small steps:

- Take a plank of scrap wood with flat surface. The size (length or width) of plank could be anywhere from six inches to one and a half feet.

- Drill four holes in the middle of the plank. The holes should penetrate the entire length of plank.

- Take one long handed heavy tool like an axe. Attach it to the plank by running two zip ties through the holes and fixing the head of the tool to the plank. Check the tightness of connections made by zip ties.

And here you go, a simple home-made earth rammer is ready.

Alternate

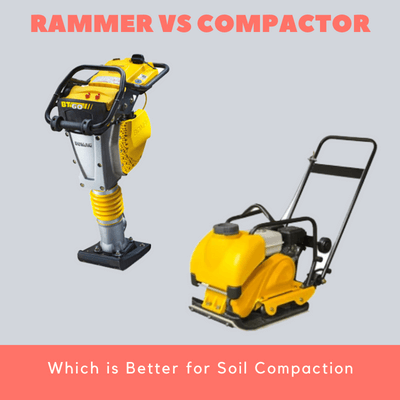

For compaction of soil, an alternate device used is a plate compactor.

Usually, Construction manager/engineers are not sure about which item should be contracted in the projects that require larger areas of earth to be compacted. That is why, it’s important to understand the difference between rammer and plate compactor.

It should be kept in mind that here we are talking about the comparison between machine powered rammer and plate compactor.

How to Choose Among Them

When choosing between the two devices, it’s vital to understand the differences between the soil types. This will help you to select the best type of equipment.

Typically, on construction sites, you will find two types of soil: Granular or cohesive soils.

Granular soils are loose soils, which can be compacted whether they’re dry or wet. They can be easily identified. If you pick them in your hand, they will crumble. Sand is a type of granular sand.

Cohesive soils have high clay content and they held firmly together. However, they need a certain amount of moisture to achieve proper compaction.

Based on these types of soils, following recommendation can be drawn for the correct type of compacting device:

- Rammers are suitable for compacting cohesive soils due to the size of their plate. Smaller plate size allows much focused and direct compaction. This is suitable for soils (e.g. clay) that require large force to properly compact.

- Plate Compactors are ideal for compacting the granular soils because they use vibrations to settle the soil particles. The plates in this case are much wider than rammer plates, which means that its weight and compaction force is spread over a much greater area.

earth rammer machine vs plate compactor

Leave A Comment