How to Grind Concrete Sidewalk the Right Way

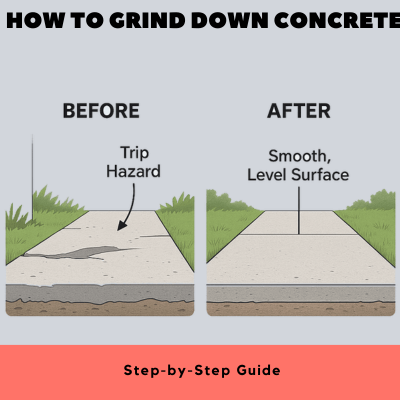

Uneven pavements are not aesthetically delightful. They are a safety risk. They cause trip hazards and injuries. They also create liability for property owners. Cracked or lifted slabs can lead to lawsuits and ADA violations.

Grinding is one of the most effective solutions. It restores level surfaces without replacing the entire slab. It is durable compared to patching. It is also cheap and prompt in comparison with replacement.

Grinding is usually selected by homeowners, residential managers, and city maintenance personnel. It is applicable at locations where the slabs have not fully frozen. At most, the slabs can be subjected to slight misalignment.

Contents

When Grinding is the Right Fix

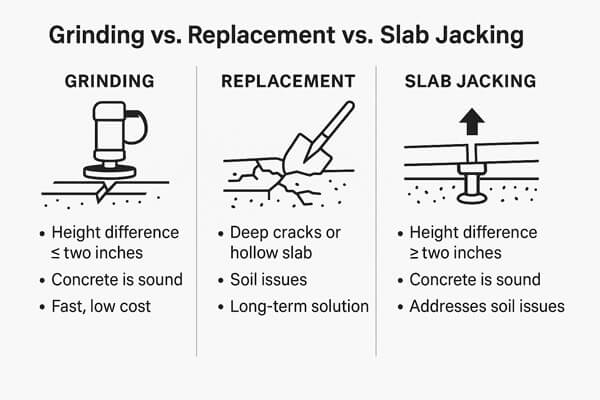

Grinding works best for small displacements. If the vertical lift is two inches or less, grinding is usually the right option. Trip hazards from tree roots or soil settlement can often be fixed this way.

It is suitable when the slab is otherwise strong. If the concrete is hollow, crumbling, or deeply cracked, replacement is better. Grinding also does not solve underlying soil issues.

Compared to slab jacking or replacement, grinding is fast. A small sidewalk section can be completed in an hour. Costs are usually far lower than removing and pouring new concrete.

If you only need surface levelling, grinding wins on speed and price. But if the slab is severely damaged, replacement is the safer investment.

Safety, Compliance & Regulations

Concrete sidewalk grinding is a process that involves safety concerns. Here, we have discussed some of them, such as:

- Grinding concrete sidewalks creates dust. That dust contains silica. Breathing silica is dangerous and can cause lung disease. OSHA has strict rules on dust control. Contractors must use water suppression or HEPA vacuums. Workers must wear respirators.

- Local ordinances may also restrict noise and dust. Many neighborhoods require permits for heavy grinding equipment. Many laws in use should be checked locally.

- The ADA (Americans with Disabilities Act) only permits 1/4-inch alterations in level. Whenever a slab on the sidewalk lifts more than half an inch, it shall either be run down or hewn down. The most inexpensive method of achieving compliance is often grinding.

- Liability is also being minimized by cutting hazards. Property owners who maintain their sidewalks stay safe. They avoid trip hazards.

- They also prevent injury lawsuits. Making an effort to be compliant and guarded is an easy solution where grinding is concerned.

Tools, Equipment & Materials

Having the appropriate tools leads to an accurate process and exact results. So, we can enlist the right tools for grinding here.

The main tool is a walk-behind concrete grinder. This machine uses diamond cup wheels to shave down raised surfaces. For small areas, a handheld angle grinder works well.

You will need diamond grinding pads. Start with coarse grit to remove height. Move to finer grits for smoothing.

A water source is important for wet grinding. It reduces dust and cools the blade. In the case of dry grinding, fit a dust shroud with a vacuum.

Safety gear is critical. Use ear protection equipment, gloves, respirator, safety glasses, steel-toe shoes. During edge work, knee pads are also present.

Beforehand, draw a circle around the area of the grid with chalk or spray paint. This makes it accurate and avoids overdoing it.

Preparation Before Grinding

Before grinding the concrete sidewalk, prepare the site and tools as follows:

- Inspect the sidewalk first. Estrange yourself on the whole slab. Look where levels are increased, or where there are cracks, or where it has voids.

- Check scour about and examine depressions. Once the cutting is done, scratch the deep cracks and mend them up, then grind them.

- Minor surface imperfections could be flattened. Patches should always be done on major cracks first. Label all the trip hazards using chalk or spray paint. This gives you a visual guide. It eliminates over-grinding also.

- Clear the area completely. Take away rubbish, dust, and furniture. Clean the dust that is likely to block the grinder.

- Wash the surface in order to minimize dust. An unstained slab also allows the grinder to work easily. It also improves pad life.

- Verify the position of the infrastructure. Search for a range of water pipes, gas lines, and electricity conduits.

- When there is more severe cutting that can be done with the local authority, confirm utility maps.

- The destruction of a utility line is immense. It may incur the expensive costs of repair. It also has the threats of fire or flood, or electric shock.

- As a way of confirming the utility locations, it is very safe to take time to check before grinding. To do the work best, the site should be prepared by day. Proper lighting is useful in identifying cracks.

- In case one is working in dark environments, then temporary lighting should be provided. Preparation helps with the reduction of errors and quickens grinding.

Step-by-Step Grinding Process

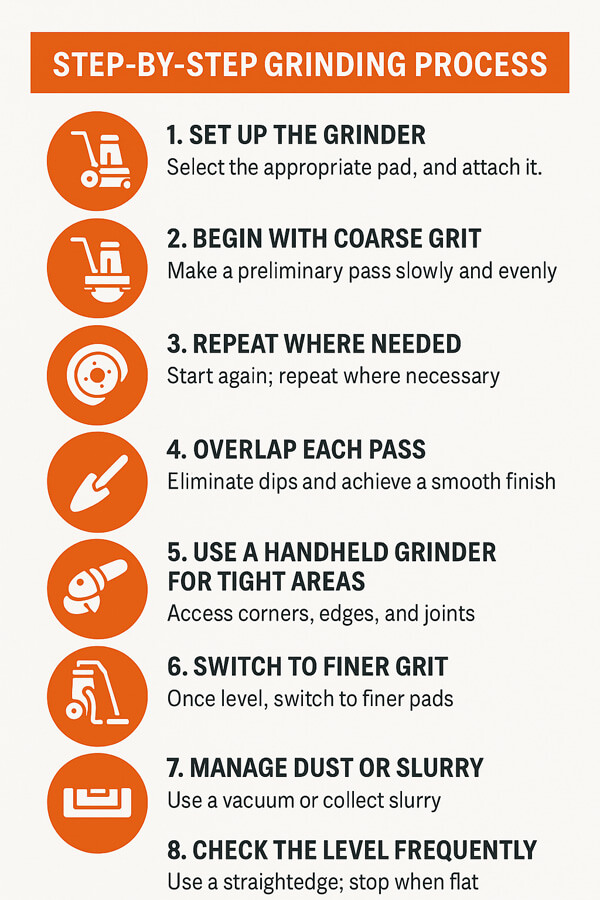

To achieve the required result, it is advisable to follow the process below.

- Begin by installing the grinder. Please select the appropriate pad and fasten it.

- Preliminary pass using coarse grit. Move slowly and evenly. Do not force the machine.

- Let the blade do the work. Start again; repeat where considered necessary.

- Overlap your strokes. This eliminates dips and has a smooth finish.

- When required to fit into tight corners or joints, then change to the handheld grinder. This assists in getting to places that are inaccessible to the walk-behind machine.

- As the surface is leveled, switch to finer grit. This step finishes the slab as well as clarifying the porosities.

- Control dust or slurry as you go. Use a vacuum system for dry grinding. If using water, wash down the area and collect the slurry.

- Check progress often. Use a straightedge or level to confirm evenness. Stop once the trip hazard is gone and the surface is flat.

Finishing & Sealing

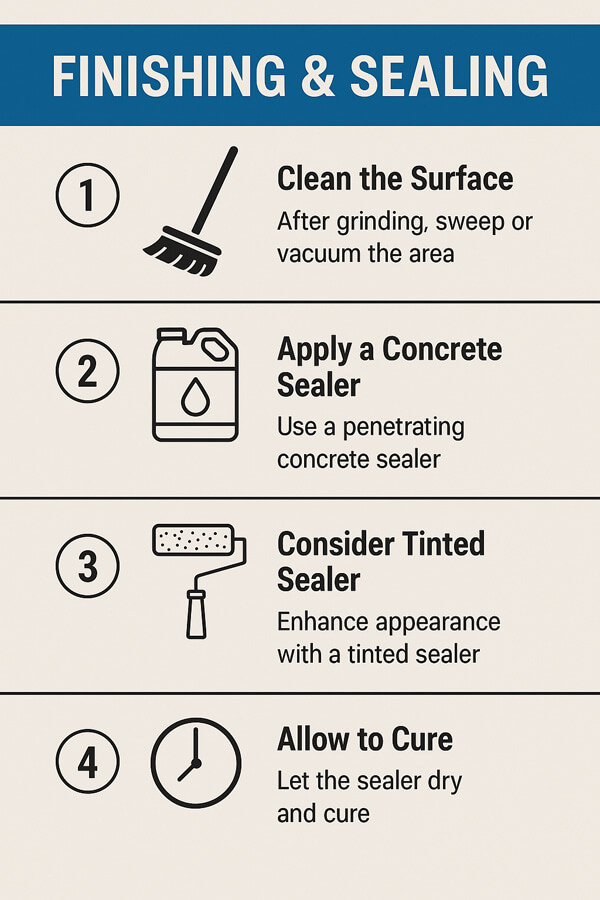

Following the grinding process, sealing and finishing will be applied. It is necessary to avoid any future deterioration. One can follow the steps:

- After grinding, sweep or vacuum the area. All dust and residue must be removed.

- Usage of a penetrating concrete sealer. That covers sidewalks against water, salt as well as stains. Sealers also improve durability.

- Some homeowners choose tinted sealers. They are capable of fixing the appearance of aging sidewalks.

- Although the sealer must dry and cure before it is reopened. Cure as per the instructions made by the manufacturer.

Pro Tips for Best Results

Grinding concrete sidewalk is a complex process and requires some special intentions. So, here are some professional tips for achieving the best results without compromising safety.

- Grind during cooler times of the day. Heat makes blades wear out faster.

- Keep the grinder moving at all times. Staying in one spot creates gouges.

- Replace worn pads early. Worn pads slow down work and produce rough finishes.

- Use guide rails or chalk lines to grind in straight sections.

Work in small areas at a time. This will avoid discrepancies and reduce errors..

Common Mistakes to Avoid

It is normal to make mistakes, however, during the grinding of the concrete surface, it is dangerous. It can lead to serious injuries. Here, some common mistakes are highlighted to avoid.

- Do not grind slabs that should be replaced. Weak or broken slabs will only worsen.

- Do not ignore dust suppression. Silica is dangerous, and compliance is mandatory.

- Do not skip grit steps. Using only coarse-grit leaves the surface rough and unsafe.

- Avoid staying in one spot. Over-grinding creates dips that can be worse than the original hazard.

- Do not forget sealing. Grinding opens pores in the concrete. Without sealing, water damage happens faster.

Alternatives to Grinding

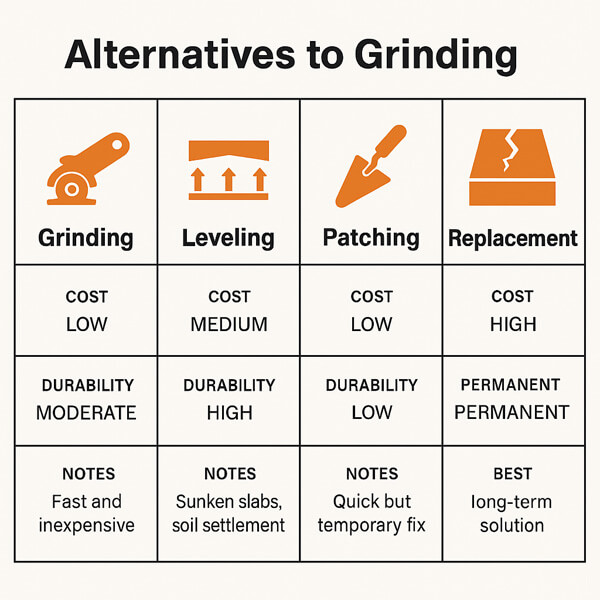

Concrete levelling is a strong alternative to concrete grinding. Methods like slab jacking, foam jacking, or mud jacking lift sunken slabs. These methods last longer than grinding in some cases.

Patching and overlays provide cosmetic improvement. They are fast but temporary. They often fail under heavy traffic.

Full slab replacement is the last resort. It is costly but necessary for crumbling sidewalks.

Comparison:

- Grinding: It is low cost, fast, and most suitable in small lifts.

- Leveling: Levelling uses a medium-cost, long-lasting remedy for sunken slabs.

- Patching: Patching is a low cost and low life technique.

- Replacement: Replacement is a high cost and permanent method and it is for severe damage.

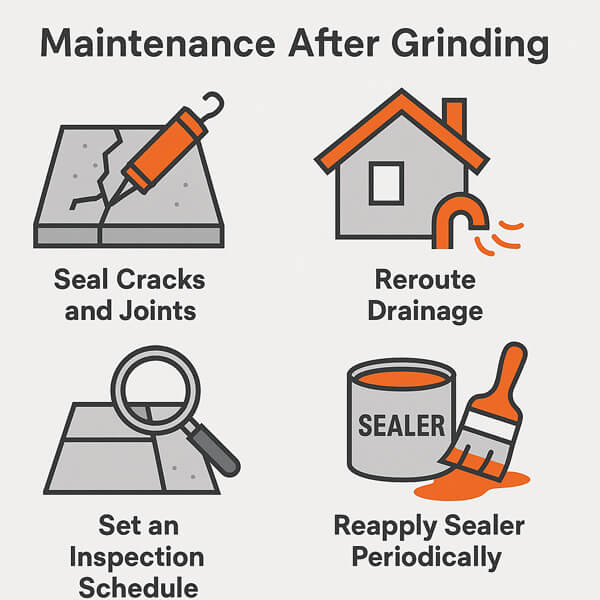

Maintenance After Grinding

Some maintenance is required after grinding the concrete sidewalk. Constant maintenance prolongs the existence of your sidewalks. Such as:

- Seal cracks and joints after grinding. This prevents water under the slab from entering.

- Reroute fast drainage and downspouts. Water should not be at the side of the walkways because it will erode.

- Establish an inspection time frame. Test the Castle walkways at least once or twice a year.

- Re-seal after every three and five years. The sealer dies down and has to be remade.

Conclusion

It will bring a sense of security, ensure compliance with the curbs, and reduce liability. It is quick and cheap to repair as opposed to replace.

They can easily grind a sidewalk in concrete with the right tools. PPEs are necessary. It is also important to prepare properly.

Always seal after grinding. Clean the surface on a regular basis.

This guarantees long-term results. A concrete walkway will be nicer. It is also safer. It reduces accidents. It lowers costs, too.

Leave A Comment