How to Grind Down Concrete: Step-by-Step Guide

A concrete grinding process involves the shaving of the surface of the slab. It is normally used in fixing up uneven walkways, rugged driveways or coated floors. People search for this solution to remove hazards, prepare surfaces, or improve appearance.

It is cost-effective compared to tearing out and replacing concrete. Grinding can extend the life of a slab if done right. However, it does not necessarily stick and particularly when the underlying cause of the phenomenon is soil settling.

Here, you shall find what is meant by concrete grinding, when to apply it, the equipment, and the process. You will also find the costs, advantages and disadvantages, options, and professional tips.

Contents

What Is Polished Concrete

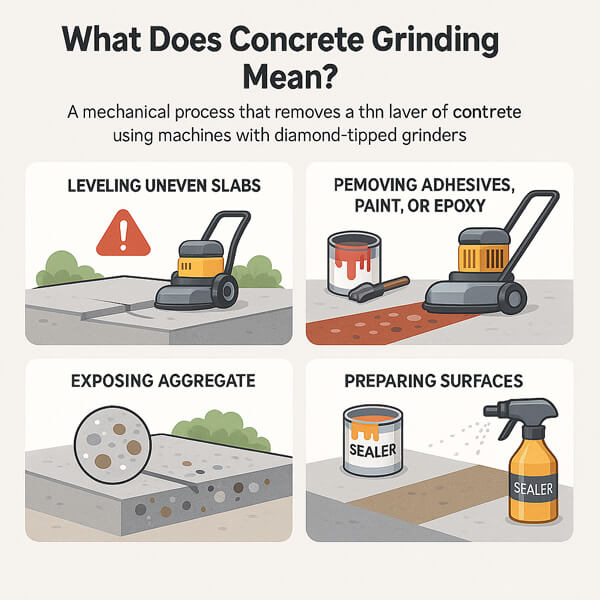

The mechanical process by which a thin layer of the concrete surface is removed is referred to as grinding. Machines that have diamond tips or discs cut material away at a slow pace. The operations are accurate and regulated. It makes it suitable for both functional repairs and decorative finishes.

The main purposes are:

- Levelling uneven slabs. This eliminates exposure to trip hazards in the sidewalks, patios or garages. Uneven slabs may soon become a safety problem. It happens to be one of the most prevalent motivations for grinding.

- Eliminating adhesives, paint or epoxy finishes. Old floors tend to require preparation prior to refinishing. Grinding removes hard-to-remove residues that otherwise interfere with new finishes. Consequently, the bonding of the coatings will not be possible.

- Exposing aggregate. One can make a decorative appearance of the stone in the concrete by grinding. With this method, many polished floors create the look of terrazzo. It is both durable and stylish.

- Preparing surfaces. Smooth slabs are easier to seal, overlay, or polish. Grinding also opens the concrete’s pores. It enhances the bonding of stains, sealers or overlays that come later.

Deep cracks or large settling are not repaired by grinding. It only addresses surface-level issues. For structural damage, other solutions like slab jacking or full replacement are usually required.

When Should You Grind Concrete

Grinding works well in many situations. Specifically, you should opt for grinding in the following circumstances.

- It is ideal for uneven slabs where one edge has lifted slightly.

- You can go for grinding in driveways, patios, and sidewalks often develop trip hazards.

- Old Oil spills and previous epoxy flooring can be polished away on the garage floor. The process eliminates the residues and provides a clean surface on which to seal.

- Sometimes commercial floors require grinding, too. Busier places need smooth finishes that are not dangerous.

- More ornamental work, such as finishes on concrete or terrazzo floors, begins with grinding.

But grinding is not always the answer. If your slab has structural cracks, deep settling, or poor subgrade support, grinding won’t last. In those cases, levelling or replacement may be better.

Tools & Equipment for Concrete Grinding

Here is the list of all the types of tools and equipment that can be used for a specific type of grinding.

Handheld Angle Grinder

A handheld grinder is perfect for small areas and edges. It uses diamond cup wheels that attach to the tool.

Pros: It is affordable, portable, and easy for DIY projects.

Cons: It is quite slow for large spaces, tiring for long use.

Walk-Behind Concrete Grinder

For larger slabs, a walk-behind grinder is best. It uses multiple discs to cover wide surfaces quickly.

These machines offer speed, efficiency, and better dust control. They are available for rent at most hardware stores.

Scarifier (Concrete Planer)

A scarifier is more aggressive than a grinder. It is mounted on rotating cutting wheels. That cut away thick coats or deteriorated concrete.

It can be used to eliminate glue, paint or uneven surfaces. But it leaves scratches which must be smoothed over sometimes afterwards.

Dust-Control & Vacuums

Silica dust is hazardous as a result of grinding. OSHA regulations require dust management. You can use wet grinding (spraying water to reduce dust) or dry grinding with HEPA vacuums. A dust extractor is essential for safe work.

Safety Gear (PPE)

Put on goggles, a respirator, gloves, hearing protection, and knee pads all the time.

Silicosis is an acute pulmonary infection that may be caused by silica dust. PPE is not negotiable as a protective measure.

Step-by-Step Guide: How to Grind Down Concrete

Now let’s have a look on the process of grinding concrete step-by-step.

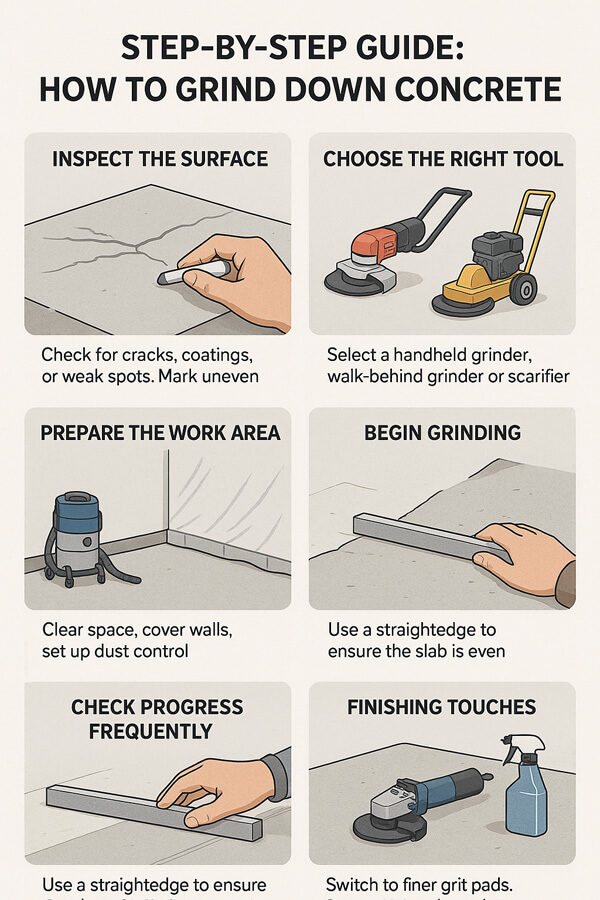

- Inspect the Surface

Check for cracks, coatings, or weak spots. Mark uneven areas with chalk. Do not grind slabs with structural problems.

- Choose the Right Tool

Select a handheld grinder for edges. You can choose a walk-behind for large areas, or a scarifier for heavy removal.

- Prepare the Work Area

Clear furniture, cover nearby walls, and set up dust control. Make sure ventilation is good if grinding indoors.

- Begin Grinding

Start at one end and work systematically. Use slow, steady passes. Let the machine do the work. Don’t force the machine to work.

- Check Progress Frequently

Use a straightedge to check flatness. If high spots remain, re-grind until even.

- Finishing Touches

When you feel like a more sophisticated look then change to smaller grit pads. Clean all dust before applying the sealer or overlay.

Cost of Grinding Concrete

Grinding is usually priced by the square foot. Prices between $2 and 8/ sq. ft., depending on your location and the state of the slab.

Some of these are: slab size, thickness, finish to be removed, and the required finish. Decorative polishing costs more than basic leveling.

DIY is cheaper if you already own a grinder. Renting equipment may cost $50 – $200 per day. Professional jobs can be more expensive but save time.

Compared to replacement, grinding is far more affordable for minor issues.

Advantages of Concrete Grinding

Here is an insight into the general advantages of concrete grinding, such as:

- Fast and affordable. Immediate results without tearing out concrete. It saves both time and labor compared to replacement.

- Improves safety. Removes trip hazards from uneven slabs. This reduces the risk of falls and potential liability.

- Versatile. Works for prep, polish, and coatings removal. You can use the same process for both functional and decorative purposes.

- Eco-friendly. Reuses the existing slab instead of replacing it. This reduces construction waste and lowers your carbon footprint.

Disadvantages & Risks

While grinding concrete, you can face the following risks:

- Only a surface fix: It does not solve underlying soil problems. If the ground continues to move, the slab will still shift.

- Makes the slab thinner: Grinding makes things slightly a bit thin. In the long run, this can decrease the load-bearing ability of concrete.

- Freeze-thaw susceptibility: Open pores will absorb water. This causes cracking in cold climates when there is a freeze towards thaw cycle.

- Patchy aesthetics: The grinding can bring forward various colors of aggregate. This can leave the surface looking inconsistent.

- May void warranty. Improper grinding can cause damage. Some manufacturers or contractors may not honor warranties if grinding is done incorrectly.

Concrete Grinding vs. Alternative

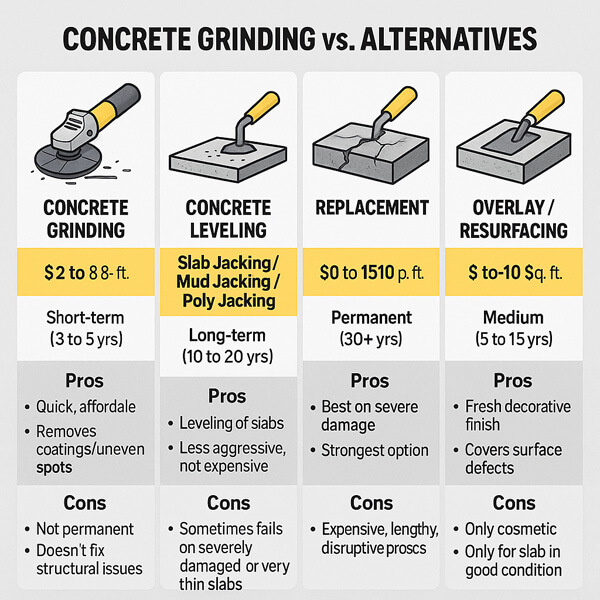

Concrete Grinding: It is recommended on small irregular areas or metal finishes. It can provide short-term fix only.

Concrete Leveling (Slab-jacking/ Mud-jacking/ Poly-jacking): These are slurry slabs and more permanent solution. It is a cheaper method than replacement.

Replacement: It is suitable for slabs that are thick, cracked or very damaged. It is the most expensive option but provide long-lasting fix.

Overlay/Resurfacing: It deposits a new surface layer. This is best for improving looks.

Comparisons

Here is a brief comparison for all the methods as below:

| Method | Cost Range (per sq. ft.) | Durability | Pros | Cons |

| Concrete Grinding | $2 to $8 | Short-term (3 to 5 yrs) | Quick, affordable, removes coatings/ uneven spots | Not permanent, doesn’t fix structural issues |

| Concrete Leveling (Slab jacking / Mud jacking / Poly jacking) | $5 to $25 | Long-term (10 to 20 yrs) | Leveling of slabs, less aggressive, not expensive | Sometimes fails on severely damaged, or very thin slabs. |

| Replacement | $50 to $150 | Permanent (30+ yrs) | Permanent best on severe damage strongest one | Expensive, lengthy, disruptive process. |

| Overlay/Resurfacing | $3 to $10 | Medium (5 to 15 yrs) | Fresh decorative finish, covers surface defects | Only cosmetic Only in good condition of slab |

Pro Tips for Best Results

To record the needed outcomes after grinding concrete, it is better to remember several following facts:

- Grind in cooler hours: This will ensure that the blades or pads do not overheat. It also helps reduce strain on the machine.

- Use guide rails or straightedges: These tools ensure precision and consistent depth. They also reduce the chance of uneven spots.

- Wet grinding reduces dust: It creates a smoother finish and keeps pads from wearing out too fast. The downside is that you must manage slurry cleanup.

- Dry grinding is faster: It requires proper dust extraction, but saves time. A good HEPA vacuum will keep the area safe and clean.

- Test a small section: Always try grinding in one area before tackling the entire slab. This helps you adjust technique and check results.

- Never grind deeper than 2 inches: Going too deep risks structural weakening. If that much removal is needed, replacement is usually better.

Common Mistakes to Avoid

To err is human, and to learn is the best practice to avoid mistakes. So, here are some common avoidable mistakes you can make while grinding concrete.

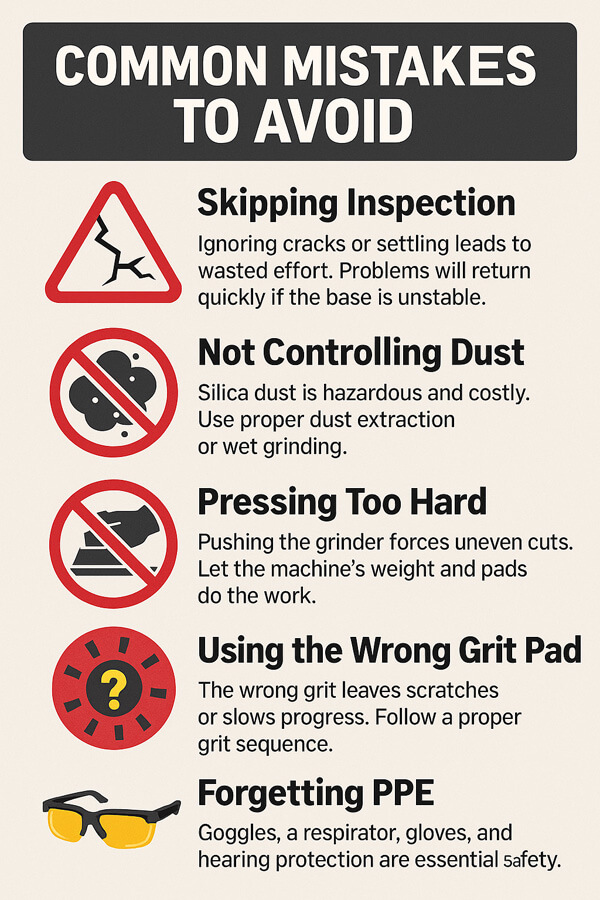

- Skipping inspection: Ignoring cracks or settling leads to wasted effort. Problems will return quickly if the base is unstable.

- Not controlling dust: Decontamination of silica dust is costly, and its health impact could be far more damaging. It is necessary to perform proper dust extraction or wet grinding.

- Pressing too hard: Pushing the grinder forces uneven cuts. Let the machine’s weight and pads do the work for a smoother result.

- Using the wrong grit pad: The wrong grit leaves scratches or slows progress. Follow a proper grit sequence for best results.

- Forgetting PPE: Safety equipment is no luxury item. The health hazards and broken arms are avoided in the long run. You can wear goggles, masks and hearing protective goggles.

Conclusion

Concrete grinding is a cost-efficient, fast and versatile way of repairing or preparing slabs. It smooths out bumps, eliminates finish and increases protection. It does not always last long, however.

Only the surface is taken care of in grinding. In longer-term fixes, also think about levelling or replacement. You can choose the right tools, introduce a portion of cautiousness, and eradicate the mistakes to be able to grind down concrete.

When done correctly, it will not only save you some money, but it will probably extend the life of your slab.

Leave A Comment