Best Saws for Cutting Asphalt: Your Complete Guide

Asphalt does not cut well with any sort of tool. It is a hard compact material. Asphalt must be cut correctly using the appropriate equipment without damaging the surface or destroy the tools.

Inappropriate saw use may result in ineffective work, safety and a lot of annoyance. When you use the appropriate one however, you will complete the task faster, safely and more effectively.

In the following guide we shall guide you through the different kinds of saw and blades. It also provides step-by-step cutting instructions, maintenance tips, and all safety tips you may require.

Are you a DIY enthusiast or professional contractor we have you covered

Contents

Understanding Asphalt as a Material

Asphalt is a mixture of aggregate (stones, sand, gravel) and bitumen (highly petroleum natural product). This combination renders it flexible, durable and hard to cut..

Why is this important

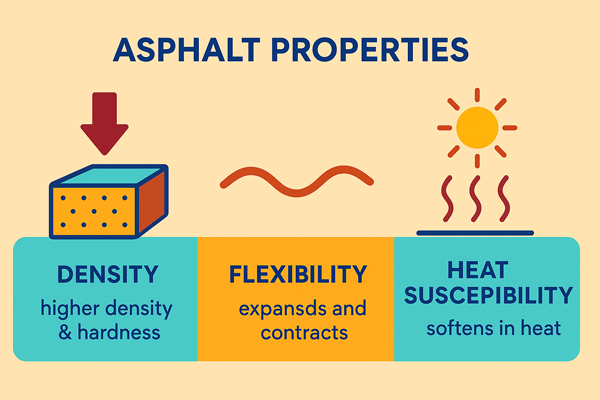

Asphalt is significant because of the fact that the material has three essential qualities. These properties are what should be taken into account and dictate how it should be cut:

- Density: Asphalt is of higher density & hardness as compared to other materials like concrete. This means that it requires more power to make the cuts.

- Flexibility: It is able to elongate and collapse with temperature differences. So, cutting asphalt has slightly different consistency of cutting. As concrete is a relatively easy cut and is more predictable.

- Heat susceptibility: Asphalt gets softened in heat.

Asphalt vs. Concrete Cutting

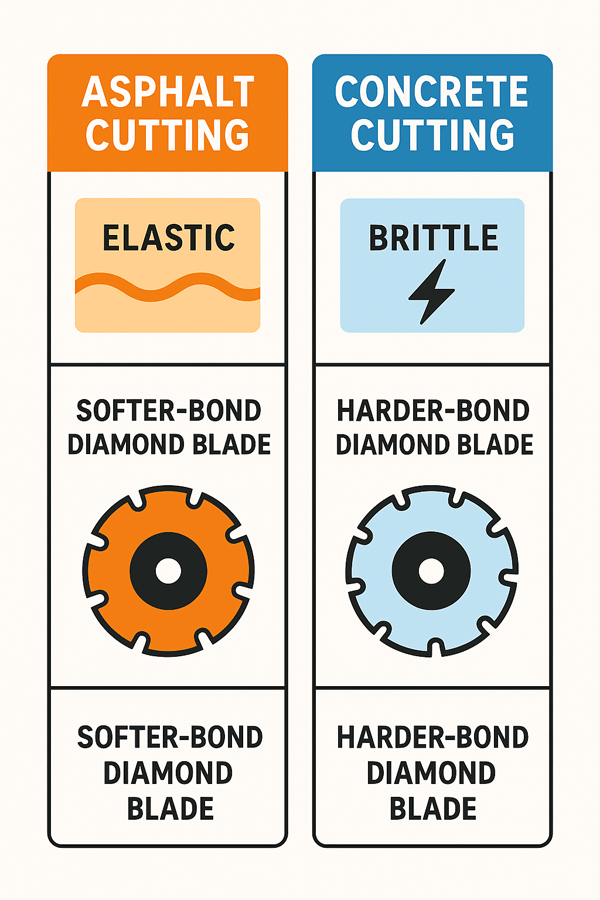

- Asphalt is elastic whereas concrete is brittle. Asphalt cutting needs a different blade, instead. Cutting asphalt requires a different type of blade. It reacts differently under the blade.

- Concrete often needs a harder, more durable blade. Whereas asphalt requires a softer-bond diamond blade. This blade keep the cutting smooth and efficient.

Main Types of Saws Used for Cutting Asphalt

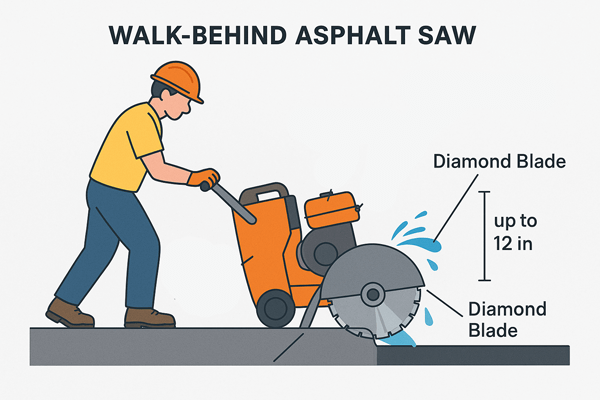

Walk-Behind Asphalt Saws

These saws are huge, heavy and powerful ones on which you walk behind as it continues to cut. They are normally employed on larger projects where accuracy and depth is an issue.

Suitable for: Road repairs and resurfacing, etc., If you are doing a lot of chopping of thick asphalt, this product is your match.

- Benefits:

- Stability and Precision: These are ideal in long cutting. They are the best when you require staying forthright and consistent.

- Depth Capacity: They are able to cut deeper and the maximum length is about 12 inches.

- Best for Big Jobs: When digging up a driveway, parking lot or a road, these saws will make the task very speedy and more accurate.

- Limitations:

- Cost: They may be quite expensive to purchase. Therefore, renting them may be a more affordable alternative when you only have one or two jobs to do.

- Heavy: They cannot be moved around and setting them up is time consuming.

- Fuel/Powder: It has longer set up time and cost addition due to the fuel or powder requirement of these saws (electricity or gas).

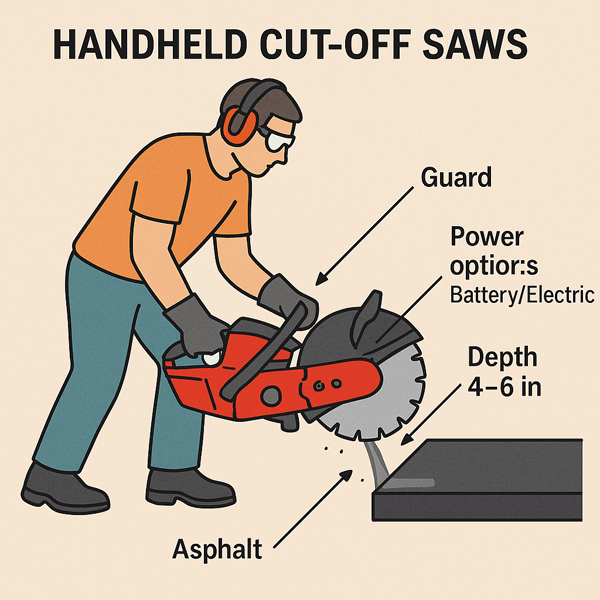

Handheld Cut-Off Saws

These are small and compact table top saws. They suit well when it comes to smaller tasks or where they cannot be reached because of the walk-behind saw.

Gas powered: They ensure the greatest power. They qualify better in large and more challenging tasks.

Battery / Electric powered: These are light and noiseless. These saws may not be powerful like their gas-powered equivalent. However, they are excellent to use in small, residential applications.

Best for: Minor repairs or utility cuts on driveways, sidewalks or residential roads. They are perfect when there is limited space you need to operate in or when you need to make some few cuts.

- Benefits

- Portability: These are easy to tote along and navigate. This means they are ideal in more confined areas.

- Fast Pace: There is no much fussing about transportation. You also do not have to install a bulky machine.

- Affordability: Handheld saws are less affordable. It may be important to note that a handheld saw is more affordable.

- Limitations:

- Limited Cutting Depth: This can only cut at 4-6 inches and may prove not enough in some projects.

- Manual Work: As compared to a walk-behind saw, they are heavier and require more manual work.

Table of Comparison

| Saw Type | Ideal Use | Depth Capacity | Portability | Typical Blade Size |

| Walk-Behind Saw | Large road projects | 8–12+ inches | Low | 14–36 in |

| Handheld Cut-Off | Small/medium jobs | 4–6 inches | High | 12–16 in |

The Role of the Blade in Asphalt Cutting

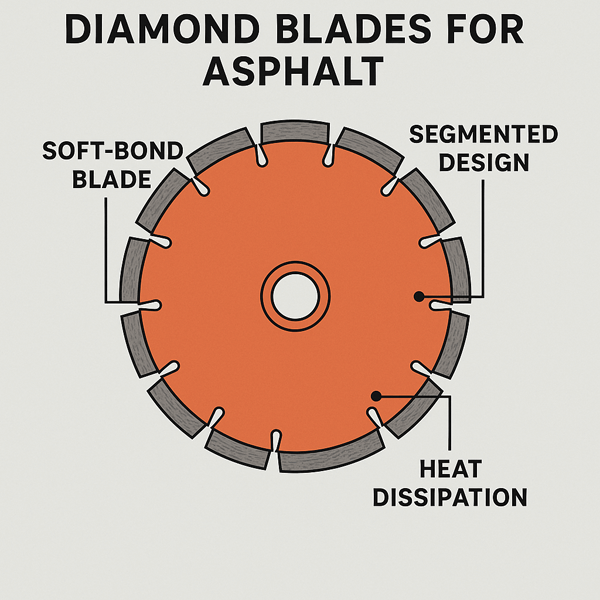

Diamond Blades for Asphalt

The most common choice of asphalt cutting is diamond blades. These blades are durable and have the ability of cutting hard materials, such as asphalt.

- Soft-bond blades: These blades in particular tackle the stickiness of asphalt. It prevents the blade from getting “glazed” over during use.

- Segment design: The segments (pieces of the blade that come to touch the asphalt) are made to aid in heat dissipation. It prevents sticking of debris. It eases the cutting process.

Wet vs. Dry Cutting

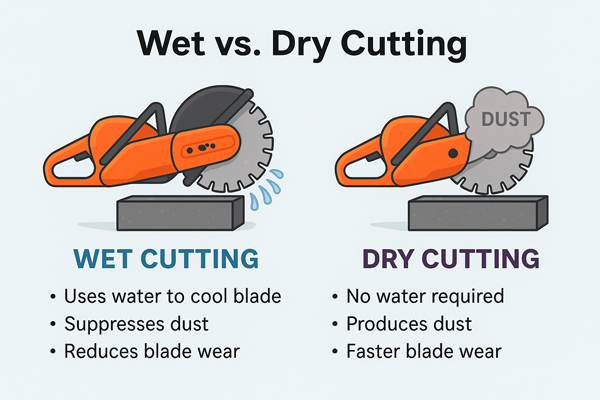

- Wet cutting: Wet cutting employs water as a means of cooling the blade as well as preventing the dust. It is the most desirable option to asphalt.

- Dry cutting: This is quicker to install but can be extremely dusty, which poses a health problem. It will also cause quicker wear on blades as they cannot be cooled guiding them so efficiently.

Tip: Try to use wet cutting when cutting on asphalt to minimize the dust and also have a cleaner cut.

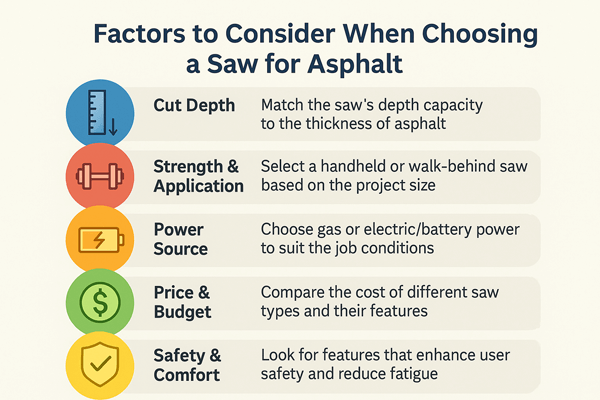

Factors to Consider When Choosing a Saw for Asphalt

As you are choosing which saw to use on your project, consider these major points:

- Cut depth: Depending on how thicker layers of asphalt you have to cut through, you will need a saw with larger depth range.

- Strength or power: A hand saw is preferred on small jobs at home. Huge work of repairing or resurfacing will need use of a walk-behind saw.

- Power: Gas-powered saws are more powerful to work on large projects. The electric saws (or the battery operated) are less cumbersome to use.

- Price: Hand held saws cost less than the walk-behind saws. However, the chances are that you will work on large-scale projects regularly.

- Safety: Look at technology such as anti stress dampeners and dust proofing. It will add comfort and safety to the use of the saw.

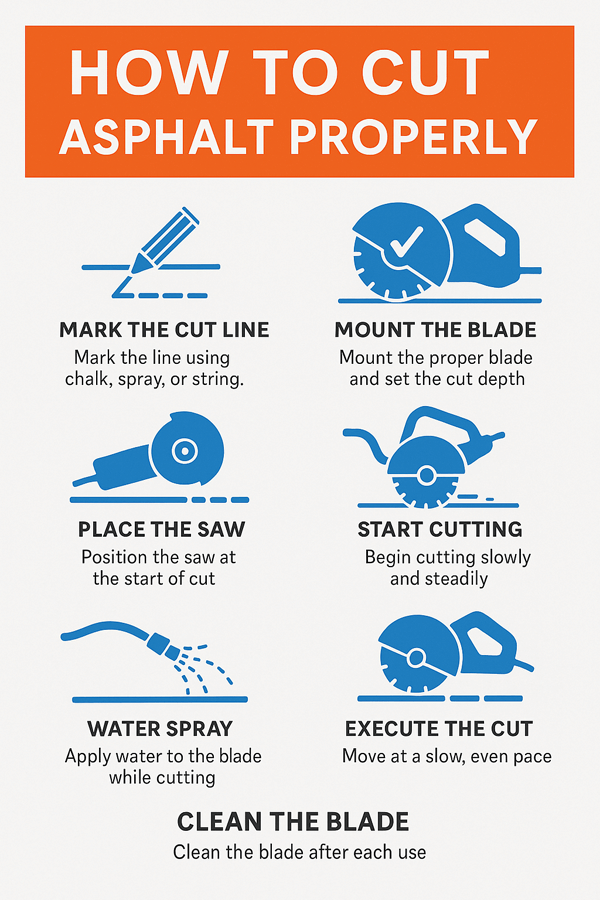

Step-by-Step Guide: How to Cut Asphalt Properly

- Mark the line of cuts: Mark the line of using chalk, sprays or string to demarcate the cut you’d like to have.

- Mount the blade: Mount the right blade and set the depth of cut to accommodate your cuts.

- Place the saw: Have the saw in position with the beginning of the cut.

- Start cutting: start slowly and make sure the saw is steady when cutting. Keep a low foot pression; use the saw.

- Water Splash: Apply water on the blade during the cut so as to cool it and reduce dust.

- Execute the cut: Slowing down towards the end of the saw, gives a smooth finish to it.

- Clean the blade: Clean the blade after each use as it is the easiest maintenance to protect it.

To improve the results, reach several shallow cuts instead of cutting deeply at a time.

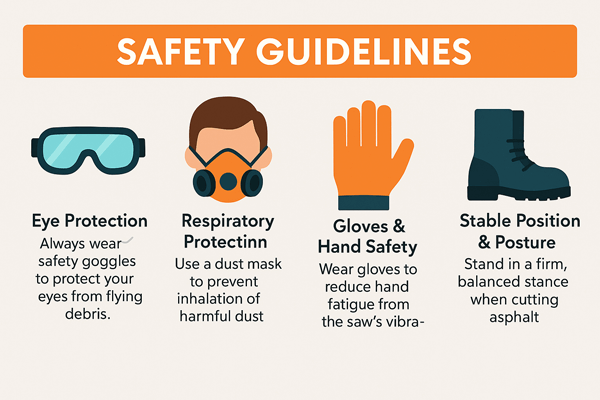

Safety Guidelines

The number one priority should be safety The following tips will also help you remain safe when cutting asphalt:

- Eye protection goggles to make sure your eyes are not roughed up by flying debris.

- Wear gas masks so that the dust is not breathed in.

- Sound protection because saws are very loud. Exposure to high level of noise can impair your hearing.

- Gloves will protect fatigue in the hand brought about by the vibrations of the saw.

- Holding a stable and upright position, you can avoid injuries and make sure you control the saw.

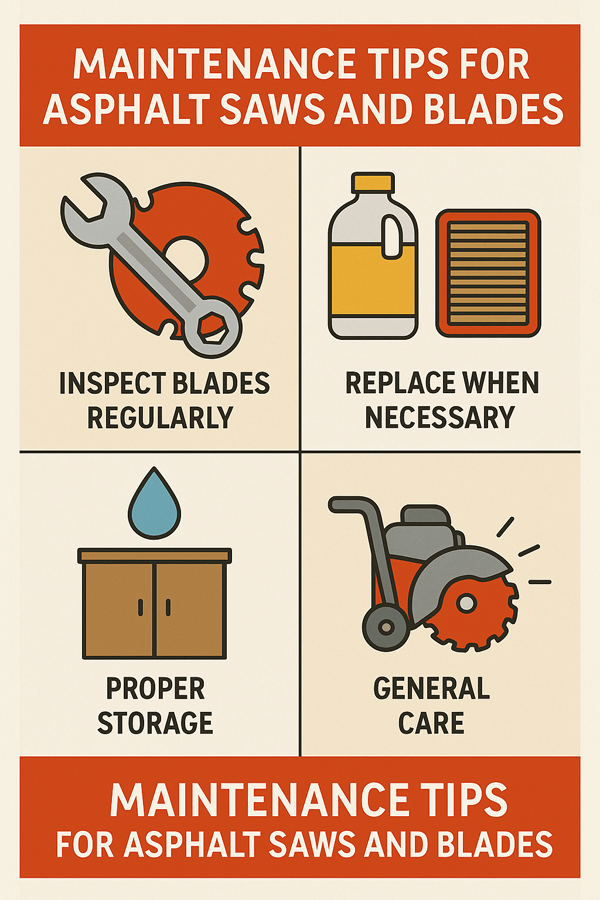

Maintenance Tips for Asphalt Saws and Blades

Adequate maintenance can make you save in the long run by making your tools last longer:

- Look at blades on a regular basis to examine and check damage, about-wear and unevenness.

- Change them when they have to Gas-powered saws change the oils and clean the air filters.

- Keep all your tools stowed when not in use so that they are not corroded.

- When the saw is not in use, maintain it in some dry place.

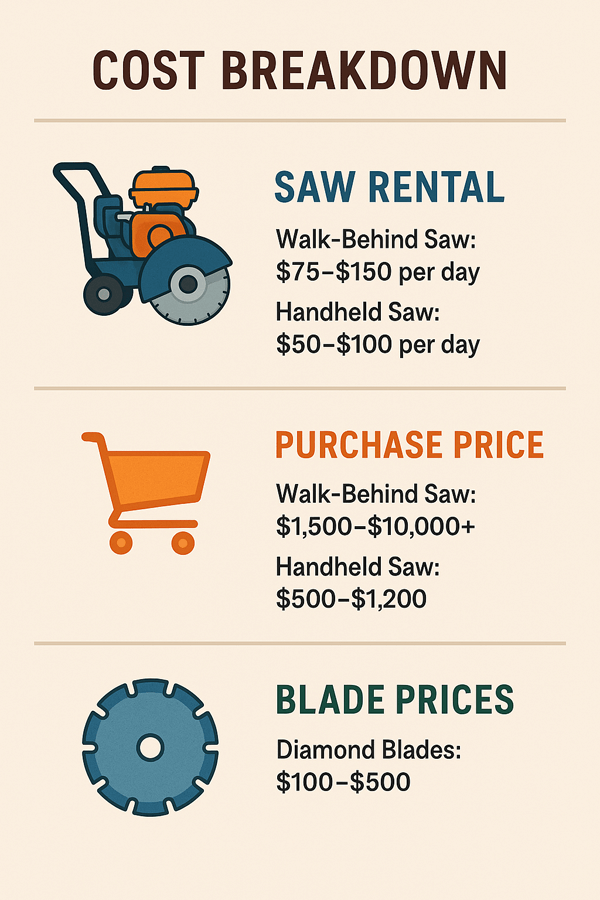

Cost Breakdown

- Saw rental: The cost to rent a walk-behind saw is approximately $75-$150 per day. Handheld saws are additional $50-$100 a day.

- Purchase price: A walk-behind saw can be priced between $1500 and $10000+. Whereas the most popular model of handheld saw retails at around $500-$1,200.

- Blade prices: Diamond blades typically retail between $100 and $500. It depends on size and quality of the product.

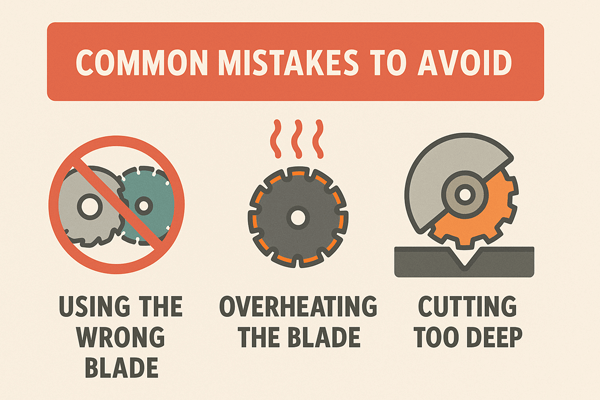

Common Mistakes to Avoid

If you are cutting asphalt, avoid the following mistakes.

- Using a concrete blade instead of an asphalt-specific blade will cause your saw to wear out.

- Overheating the blade by cutting without taking breaks will damage the blade and asphalt.

- Cutting too deep unnecessarily wastes time and energy. Shallow cuts are often all you need.

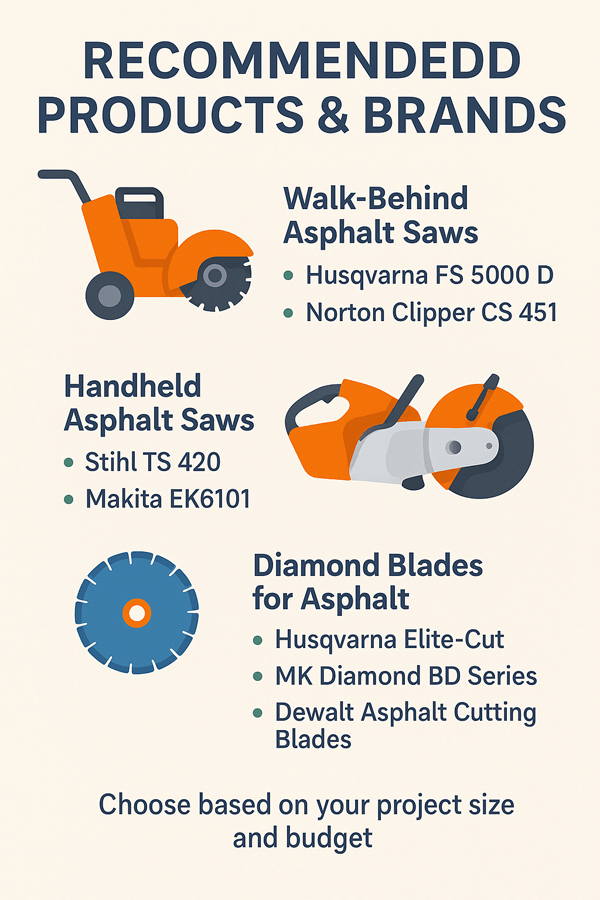

Recommended Products & Brands

Walk-Behind Asphalt Saws

- Husqvarna FS 5000 D

- Norton Clipper CS 451

Handheld Asphalt Saws

- Stihl TS 420

- Makita EK6101

Diamond Blades for Asphalt

- Husqvarna Elite-Cut.

- MK Diamond BD Series.

- Dewalt Asphalt Cutting Blades.

Choose based on your project size and budget.

Conclusion

Asphalt cutting is a challenging task that needs appropriate saw and saw blade. Walk-behind saws will work well when you want to do large work and deep cuts. Hand saws are aptly suited to small tasks. Put the focus on safety as well as care of your equipment best outcomes.

FAQ Section

Can you use a concrete saw blade to cut asphalt?

No. Asphalt needs a soft bond diamond blade.

What’s the maximum depth you can cut with a handheld saw?

Usually 4–6 inches.

Do you need water to cut asphalt?

It’s best. Water cools the blade and reduces dust.

Is it better to rent or buy an asphalt saw?

For one-time jobs, rent. For frequent use, buy.

How long do asphalt blades last?

It depends on depth and material. On average, 30–60 hours of cutting.

Leave A Comment