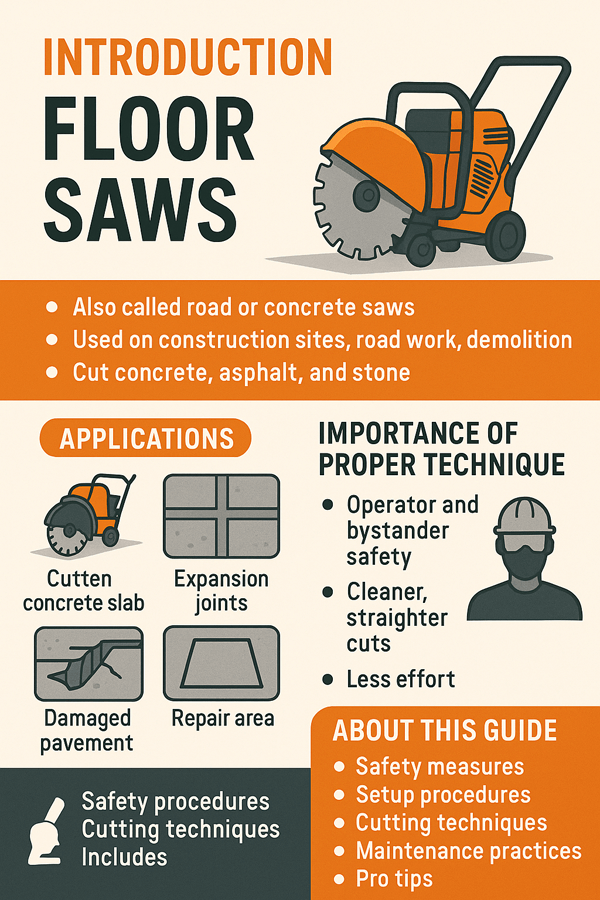

How to Use Floor Saw on Concrete Like a Pro [Step By Step]

A floor saw is also called a road saw or a concrete saw. It is a powerful machine designed to cut hard, flat surfaces. It is used in roads construction sites, in road works and in demolition.

Floor saws are concrete slabs, asphalt roads, and stone surfaces cutting. It becomes necessary to provide expansion joints in concrete floors. They also have the capability of removing damaged sections of pavement. They can mark areas ready to repair.

It is highly important to use the relevant technique. Proper working enhances the safety of the operator and the surrounding people. It also produces cleaner, straighter cuts with less effort.

This guide explains how to use a floor saw step by step. It covers safety, setup, cutting techniques, and maintenance. It also includes pro tips and common mistakes to avoid.

Contents

Understanding Floor Saws

Floor saws are essential in construction and roadwork. They create expansion joints in concrete slabs. They help in removing damaged pavement sections. They are also used in demolition. It cuts large floor sections into smaller, removable pieces.

What is a Floor Saw

A floor saw is a machine designed to cut flat surfaces. It has a large rotating blade mounted on a wheeled chassis.

Floor saw is a heavy-duty cutting machine used on flat surface. It can be used for virtually all concrete, asphalt, stone cutting and all other hard surfaces. The saw comes with a big diamond blade attached to a wheeled trolley.

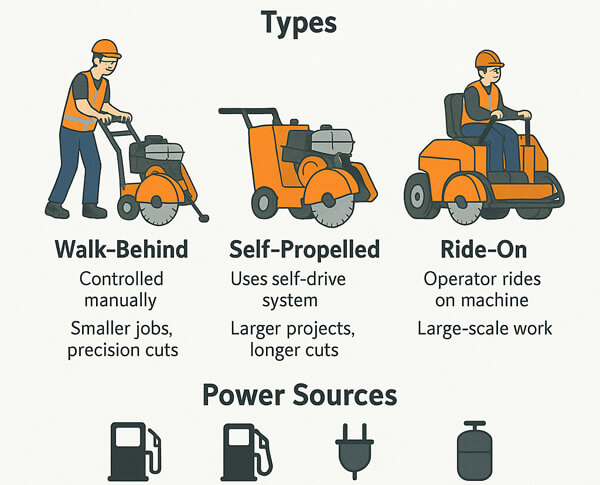

Types

- Walk-behind: Controlled manually by pushing from behind. Best for smaller cuts and lighter jobs where precision is key.

- Self operated: It moves along a self-drive system. They are good for large size projects and longer cuts.

- Ride-on: The machine will have a seat where the operator will sit to turn the machine.

Power sources vary. You can find petrol, diesel, electric, and hydraulic models.

Key Components

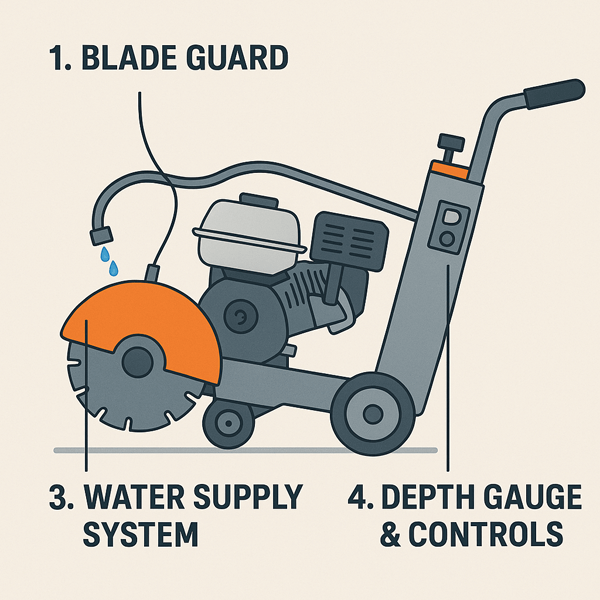

Main parts of floor saw are:

- Blade Guard: Protects the operator from debris. He must avoid sparks, and accidental contact with the blade during operation.

- Diamond Blade: Can be segmented for aggressive cutting. It may be continuous rim for smooth cuts, or turbo for faster penetration.

- Water Supply System: Directs water onto the blade to reduce heat. It also controls dust, and extend blade life.

- Depth Gauge & Controls: Lets you set and adjust cutting depth accurately. It will avoid overcutting or damaging the surface below.

Choosing the Right Floor Saw and Blade

Choosing the right blade is the key to the accurate cutting. You must consider the following:

Factors to Consider When Selecting a Floor Saw

Some important points to cater are:

- The size of the job and the thickness of the concrete: Light weigh machine can handle thin slabs. Thicker and strengthened concrete is worked on by bigger and heavier saws.

- Indoor vs. outdoor use: Electric saws produce no fumes. It makes them safer for indoor cutting. Petrol and diesel saws are better for open outdoor spaces.

- Power source suitability: Match the saw’s power type to your site conditions. It must be according to available fuel, and mobility requirements.

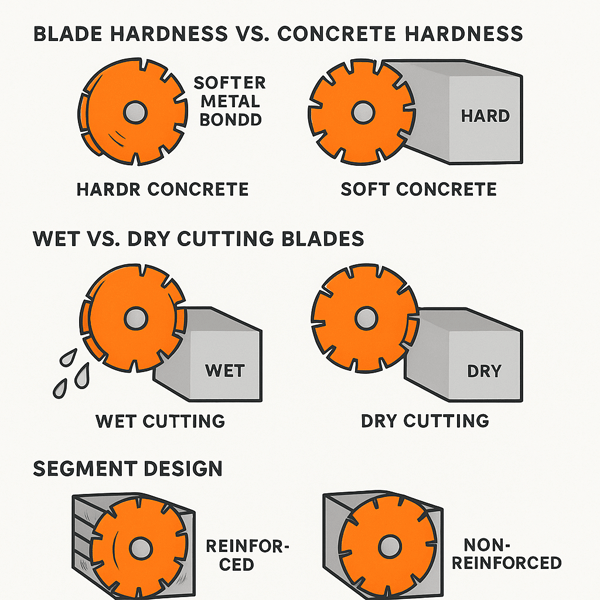

Selecting the Right Diamond Blade for Concrete

For selecting the diamond blade, consider:

- Blade hardness vs. concrete hardness: Use a softer metal bond for hard concrete. It will be required to expose diamonds faster. Use a harder bond for softer concrete to prevent rapid wear.

- Wet vs. dry cutting blades: Wet blades cuts down dust & heat, good for long continuous cuts. Dry blades are suitable for short, quick cuts where water isn’t available.

- Segment design: Choose blades designed for reinforced concrete when cutting through steel bars. Use non-reinforced blades for plain concrete to reduce cost and wear.

Preparing for the Job

There are some common steps that are essential while preparing for the job.

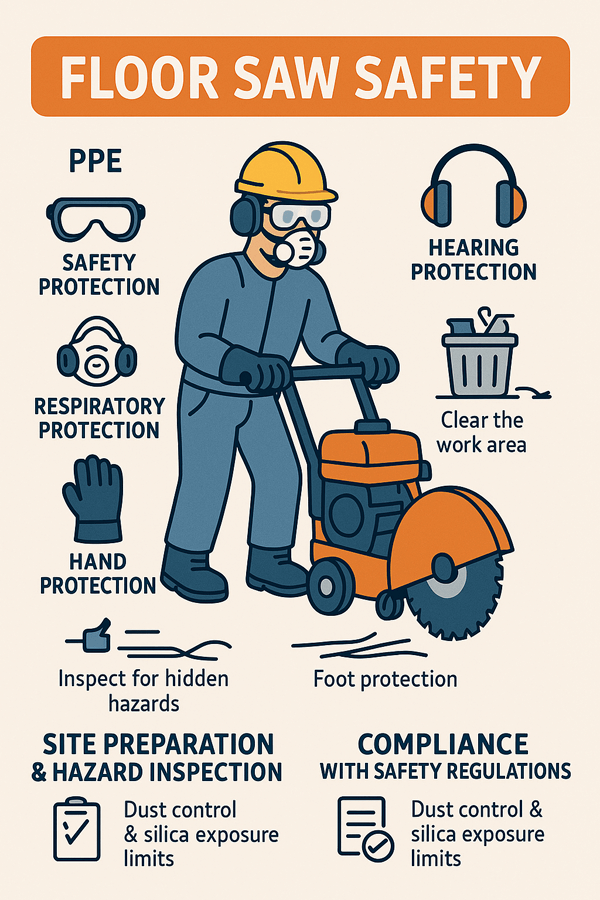

Safety First

Always ensure your safety before operating a floor saw.

- PPE: Take care of your eyes by wearing safety vision safety at all times. Use protection of the ears to eliminate hearing loss. Wear a respirator or dust mask to be safe to your lungs. Use heavy-duty gloves to avoid hand injury and steel-toe boots to avoid feet injury.

- Preparation of the site and inspection of hazards: You are supposed to clear garbage. Never leave clutter. Make sure that there are no secret utilities such as electric wires or waterlines etc.

- Conformity laws: Comply with all local dust control, safety laws. They must be including any silica dust exposure limits and noise restrictions.

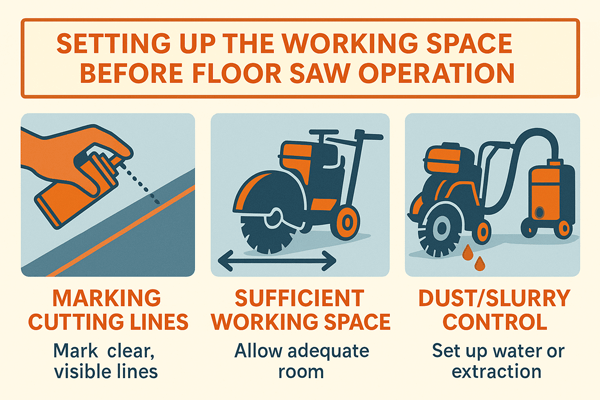

Setting Up the Work Area

Before start operations, set up your working space by:

- Marking cutting lines: You can just use chalk, spray paint to mark clear, visible lines where to cut.

- Sufficient working space: There should be adequate space for saw to move freely. This is more so with lengthy straight cuts.

- Dust/Slurry control: Set up water drainage on cutting under wet conditions. You can also set up on dry-cutting where there is the utilization of dust extraction.

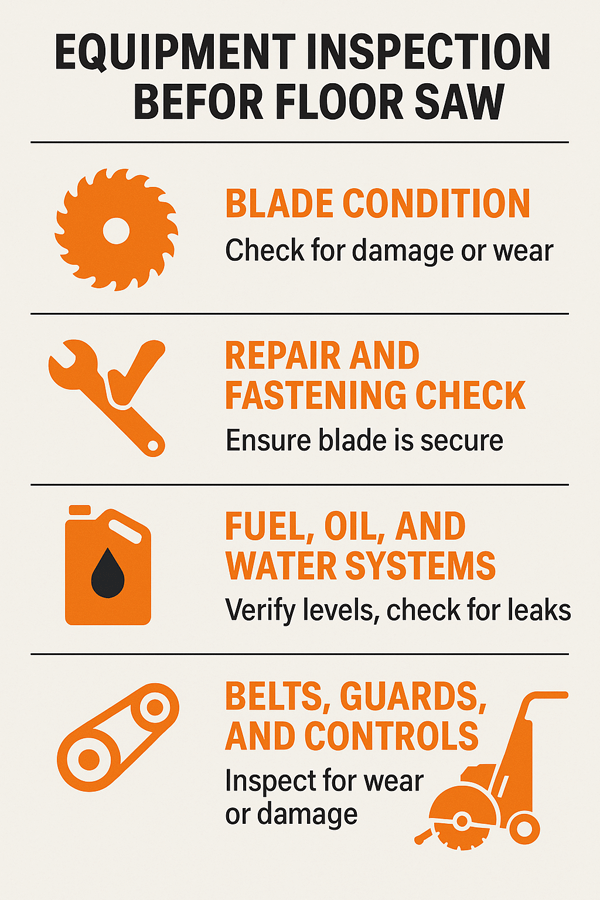

Equipment Inspection

Equipment must be inspected as follows:

- Blade condition: Check on parts missing or cracks, or over-worn parts. They may lead to failure in the course of the cutting operations.

- Repair Analysis: Check the repairs and see that the blade is well fastened and secure the arbor nut.

- Fuel, oil and water system: Look at levels if they are proper and there are no leaks.

- Belts, guards and controls: Check to see if there is wear or damage. So that mechanical breakdown does not occur.

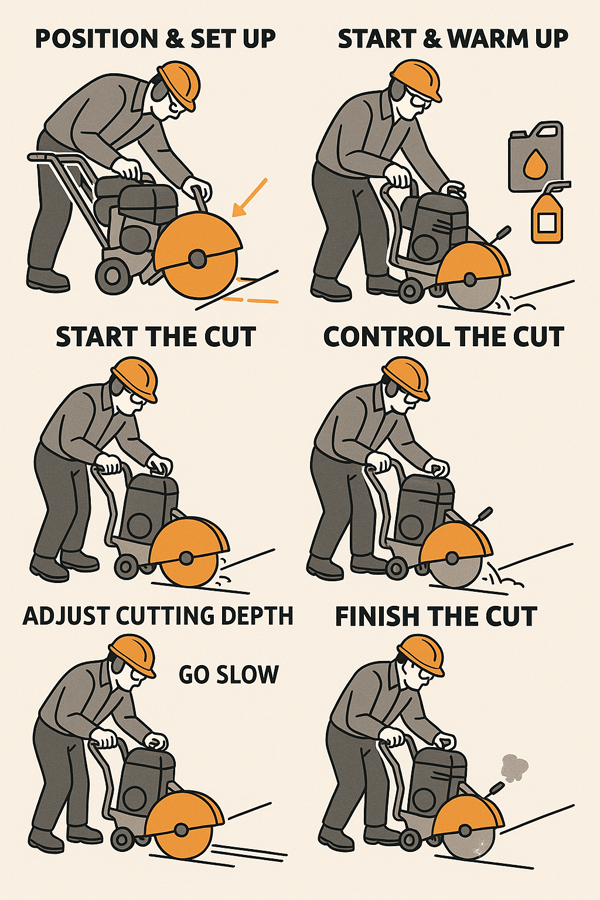

Step-by-Step Guide to Using a Floor Saw on Concrete

Here is a step by step for using a floor saw

Step 1: Positioning the Saw

- Get a line before you start to match it with the saw.

- Set the size of the blade in sufficient depth.

Step 2: Plot saw on

- In the second step, the saw should be plotted on.

- In case of petrol and diesel vehicles, test fuel and oil prior to ignition.

- Put the saw on and notch it into a warm state.

Step 3 The cut-start- makings

- Suddenly dropping the blade will never get you into the concrete.

- Then the blade must be fully engaged and proceed to go forward.

Step. 4: Control Cut

- Pound down hard nothing on blade.

- Cutting should be done at its slow pace so as to avoid overheating.

- Keeping the blade cool is the key for wet-cutting. You must monitor water flow.

Step 5: Adjusting Cutting Depth

- Have few shallower cuts rather than one deep one for deep cutting.

- In cutting reinforced concrete, go slowly on striking the steel reinforcement.

Step 6: Finishing the Cut

- Raise the blade completely before moving away from the cut.

- Turn off the saw and allow it to cool before storage.

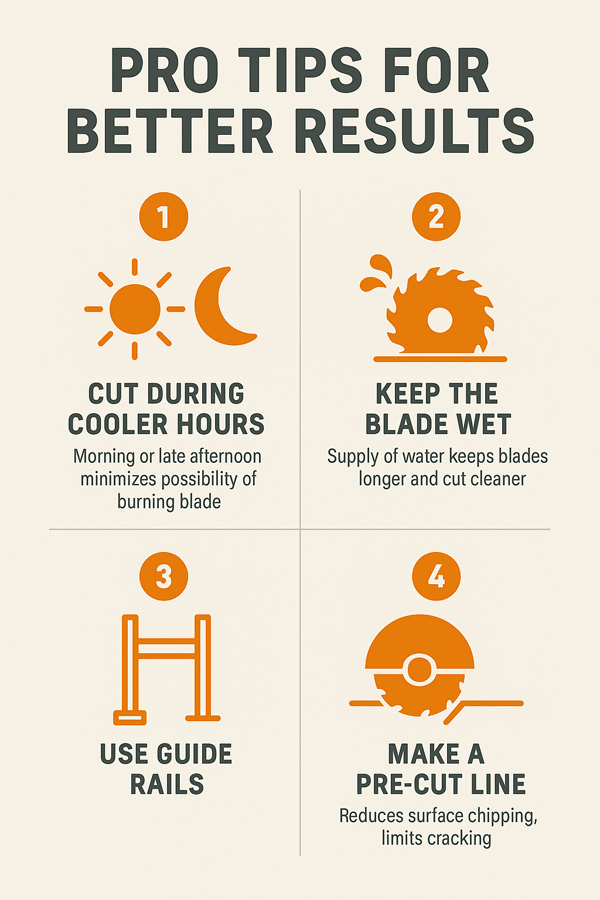

Pro Tips for Better Results

- Cut during cooler hours: Morning or late afternoon minimizes the possibility of burning the blade.

- Wet your blade: Supply of water keeps the blades longer and reduces the amount of dirt that gets into the cuts.

- Guide rails: It is portable. It also aids the creation of very straight and professional cuts almost every time.

- Pre-cut line: Cut shallowly before getting full-depth cut. It is important in order to remove surface chipping, and limiting cracking.

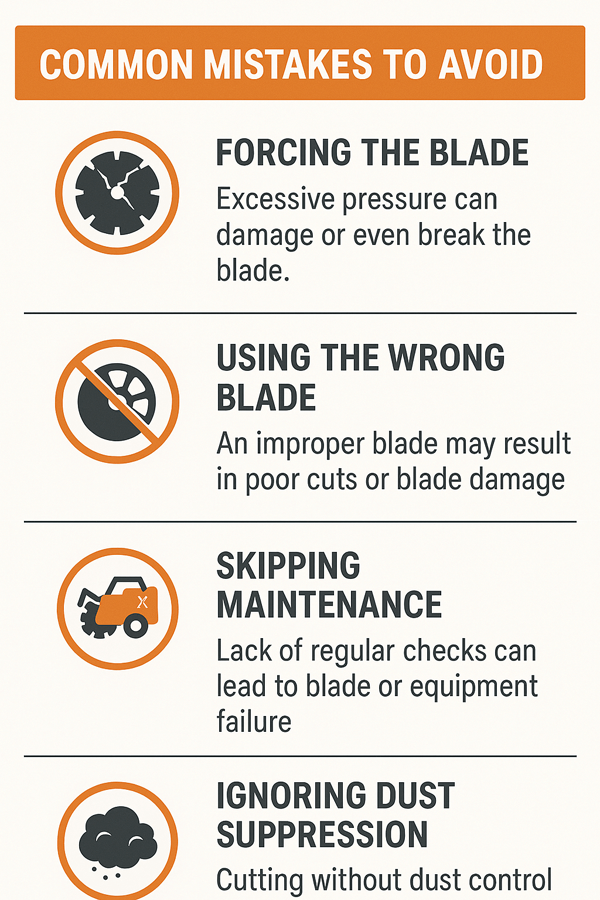

Common Mistakes to Avoid

In order to cut safely and adequately, always avoid:

- Forcing the blade: It is upsetting the blade more than needed that leads to wearing out and may even break.

- Improper blade: Putting an asphalt blade on concrete may damage the blade. It would result in unsatisfactory cuts.

- Failure to maintain: Failure to go through regular checks can lead to blade damage. The lubrication of the blades may result into expensive mid-job breakdowns.

- No dust suppression: It is dangerous to health. Moreover, it can lead to legal liabilities to cut without dust suppression.

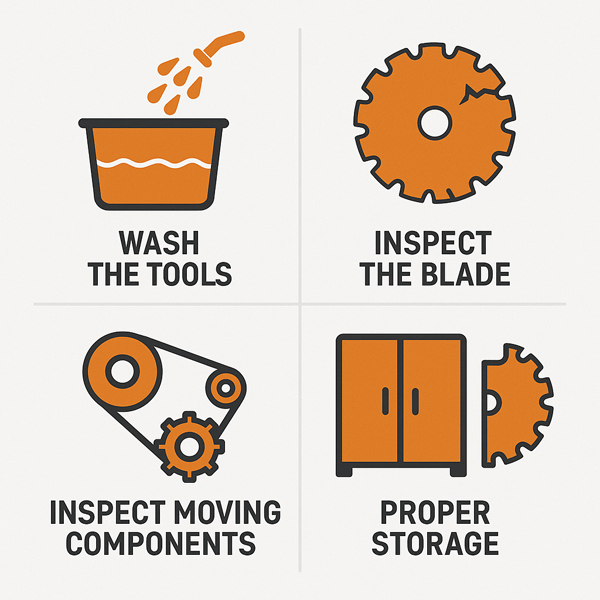

Maintenance After Use

A machine can only long-last if maintain fully. You must:

- Wash the tools: Wash the tools on all sides which may be of concrete slurry or dust.

- Take a look at the blade: Is it worn out, cracked or broken at some places?

- Inspect moving components: Inspect to determine whether belts, pulleys and bearings are intact.

- Storage: Store in dry place with the blade being taken apart in order to dry it.

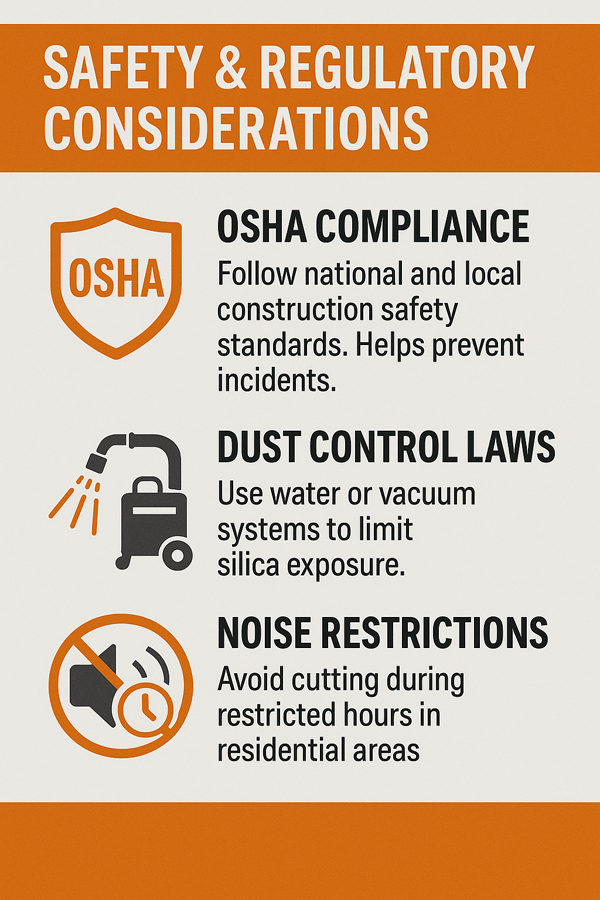

Safety & Regulatory Considerations

- OSHA compliance: OSHA compliance saves you from incidents. You must follow national and local construction safety standards during the operations.

- Dust control laws: Use water or vacuum systems to prevent silica exposure.

- Noise restrictions: Avoid cutting in restricted hours in residential zones.

Conclusion

The efficient use of a floor saw early preparation. An appropriate technique and timely maintenance. Using the right saw and blade on the job gives cleaner cuts as well as saving on equipment.

Safe and efficient worksite is efficient. Observing every cutting procedure helps to avoid cutting of the blades. After use, it is good to maintain it by following some routine maintenance. Saw needs to be in a perfect shape during future projects.

There are special precautions, such as PPE, dust control. These safeguard both the operators and people. With experience, little time, and sufficient precaution in hand, you can perform professional. It can result in precise and safe cut each and every time.

FAQs

Can a floor saw cut asphalt?

Yes. Use an asphalt-specific blade for best speed and finish.

What’s the maximum depth a floor saw can cut?

Most floor saws cut between 100–450 mm depending on blade size and machine power.

Can I use a dry blade with a wet saw?

Yes, but really better to match the cut to the blade for the safety of both you and the blade for those matters.

How do I cut concrete indoors with minimal dust?

Use an electric saw with a wet blade and a water system for dust suppression.

Leave A Comment