4 Kinds Wire Straightening Machines: How To Use Them

wire straightening machine for sale start from $350

Contents

Wire Straightening Machines (For Scrap Wire Pieces)

Working in a construction site, you will be dealing with a lot of excess scrap materials. Most of these are from cutting metals, rebars and wires. You may think that after it is cut, all of these are considered as waste and a loss but thinking outside the box, it can actually still be usable and you can even earn money from these scrap wire material. One way of making use of these bent scrap wire is allowing it to pass the wire straightening machine wherein it your desirable straightness will be achieved.

Most of these straightening machine looks differently, but the components of the machine actually are the same and present to all.

- Single of Dual Rollers (which there also different grove design)

- Adjustable Screw for Rollers (to adjust the tightness)

- Feeder (where you let the bent wire in)

How do you use the wire straightening machine?

- First is to know the diameter of your wire and use the roller size and the number of rollers required for the said bent wire. Optional: if the machine has different groove style, you can also use it depending on your desire.

- Next, now that you have attached the rollers, adjust the tightness of the rollers using the screw that you can see on top of the machine. The roller size have different weight which the tightness of these roller will affect the bending process.

- Now that you have adjust the necessary tightness, the number of rollers and the required roller size, feed the bent wire into the machine. As you feed the bent wire in the wire straightening machine, it will pass through the rollers, where it will be applied with the different weight, and through its spinning mechanism, pushes it out the straightening machine.

- With the result, you can check if it is your desired straightness of the wire. If not, pass it through the wire straightening machine until you have achieved the desired straightness of the wire.

- Do it to the remaining scrap wire.

This wire straightening machine can accommodate wires with 2 to 5 mm in diameter and has a speed of greater or equal to 28m/ min. The power required for this wire straightening machine is 3kW.

Wire Straightening And Cutting Machine(For Wire Coil)

Coiled wire are mostly pre-made but coiling of wire is possible for the purpose of keeping long wires neat and intact to each other. Since wire are bendy and flexible, it can easily be coiled but the problem arise because it cannot come back to its straightened form. After you have rolled it over, the spring-like result cannot be manually straightened and impossible to perfect. Thankfully because of the advancement of the machine, we now have wire straightening machine that also be cut in your desired length which can save you time and effort. Using the wire straightening machine with cutting mechanism is a wise investment.

Most of these straightening and cutting machine looks differently, but the components of the machine actually are the same and present to all.

- Single of Dual Rollers (which there also different grove design)

- Adjustable Screw for Rollers (to adjust the tightness)

- Cutter

- Feeder (where you let the bent wire in)

How do you use the coiled wire straightening and cutting machine?

- First is to know the diameter of your wire and use the roller size and the number of rollers required for the said bent wire. Optional: if the machine has different groove style, you can also use it depending on your desire.

- Next, now that you have attached the rollers, adjust the tightness of the rollers using the screw that you can see on top of the machine. The roller size have different weight which the tightness of these roller will affect the bending process.

- Now that you have adjust the necessary tightness, the number of rollers and the required roller size, feed the bent wire into the machine. As you feed the bent wire in the wire straightening machine, it will pass through the rollers, where it will be applied with the different weight, and through its spinning mechanism, pushes it out the straightening machine.

- When it is pushed through the machine, the wires will be cut in your desired length until it have finished the entire wire length.

With this straightening and cutting machine, it is with quality and efficiency as it can produce cut-out wires which as well are straightened first. These straightening and cutting machine can be used for wires with diameter of 2 to 5 mm. The speed can be up to 35m/min and more and the power used for these machine 4.75kW.

Wire Rod Straightening And Cutting Machine(For Wire Coil)

Wire rod bending capacity depends on the material and its properties. The slenderness of the wire rod is the ratio of the cross-section to its effective length. The higher the slenderness of the wire rod, the easier it is to be bent. As you bend the wire rod, it can not be easily brought back to its original form because of its stiffness. The bend of the wire rod can be in the shape of V and U where it can also indicate the strength of the wire rod. One way of straightening the wire rod is through the straightening machine and if needed to be cut, in a hybrid machine that can accommodate the cutting after straightened.

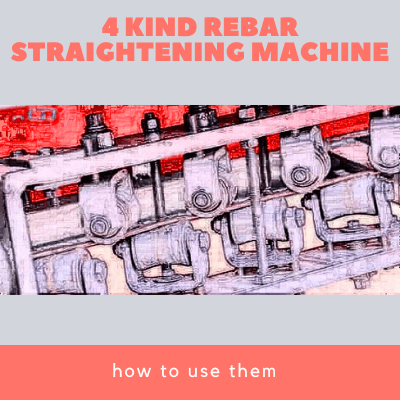

Most of these straightening and cutting machine for the wire rod looks differently, but the components of the machine actually are the same and present to all.

- Multi-axial Rollers (which there also different grove design)

- Adjustable Screw for Rollers (to adjust the tightness)

- Control Machine

- Feeder (where you let the bent wire in)

How do you use the wire rod straightening and cutting machine?

- Use the required roller sizes for your wire rod diameter. Adjust the number of rollers need for the straightening process.

- First, feed the wire rod to the machine. DO NOT TURN THE MACHINE ON, as it might cause accidents. Pull it through the rollers.

- After pulling it through the rollers, adjust the screws to tighten the rollers where the wire rod passes through. The screws can be seen just on top of the rollers.

- After done the adjustments, turn on and control the spinning speed of the machine and customize the length of cut after the wire rod is straightened.

- After making the necessary steps, feed the wire rod until all of the wire is being accommodated.

- If necessary, allow it pass through the machine a couple of times to achieve the straightness of the rod.

These straightening and cutting machine can be used for round bar with diameter of 4 to 12 mm and rebar with diameter of 5-10 mm. The speed can be up to 35m/min and more and the power used for these machine 7.55kW.

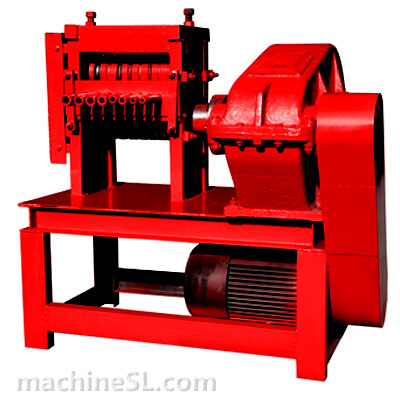

Rod Straightening And Cutting Machine(For Wire Coil)

This type of machine is also used for straightening round bar and rebar but is built to be more efficient. This machine can accommodate round bar with diameter ranging from 4 to 14mm and rebar diameter from 4 to 12mm. Compared with the smaller rod straightening and cutting machine, the speed can be up to 70m/min and higher. The power required for this machine is 20.5kW.

The process in using these machine is just the same with the smaller version.

- Use the required roller sizes for your wire rod diameter. Adjust the number of rollers need for the straightening process.

- First, feed the wire rod to the machine. DO NOT TURN THE MACHINE ON, as it might cause accidents. Pull it through the rollers.

- After pulling it through the rollers, adjust the screws to tighten the rollers where the wire rod passes through. The screws can be seen just on top of the rollers.

- After done the adjustments, turn on and control the spinning speed of the machine and customize the length of cut after the wire rod is straightened.

- After making the necessary steps, feed the wire rod until all of the wire is being accommodated.

- If necessary, allow it pass through the machine a couple of times to achieve the straightness of the rod.

wire straightening cutting machine for sale start from $350

Leave A Comment