5 Different Types Concrete Joints: How To Make & Repair and What to Fill

Concrete is a construction material used for various types of civil engineering applications like buildings, bridges, roads, foundations, dams, etc. The concrete is essentially produced by mixing appropriate quantities of cement, sand, aggregate, and water.

In some cases, concrete is also reinforced with steel rebars. Such type of concrete is called reinforced concrete.

For several reasons, the surface of the concrete is cut to create a space between. The open space between the two surfaces is called the joint.

In this article we will see, what are the different types of joints, how we can make them, and how we can fill them if they are needed anymore.

Contents

Why We Need Concrete Joints

Joints in concrete are created to compensate for the expansion or shrinkage in concrete due to changes in temperature.

To prevent the cracks caused by shrinkage and expansion, joints are created by forming, tooling, sawing, and placing joint formers in the concrete.

As a result of these pre-planned cracks (joints), cracking will not develop in concrete and a better-finished surface would be obtained. Additionally, the opening and closing of these preplanned concrete cracks (joints) can easily be monitored.

Apart from prevention of cracks from expansion or contraction, concrete joints are sometimes made due to the material and span of the concrete. In such cases, the joint allows free movement of concrete due to its expansion and prevents damage to the other structural elements connected to the concrete.

Concrete joints can be found in the following types of structures.

- Floor slabs

- Pavement slabs

- Bridge decks

- The interface of two types of structures (wall and floor or columns and floor slab, etc.)

- New concrete structure built on an existing concrete structure

Types of Concrete Joints

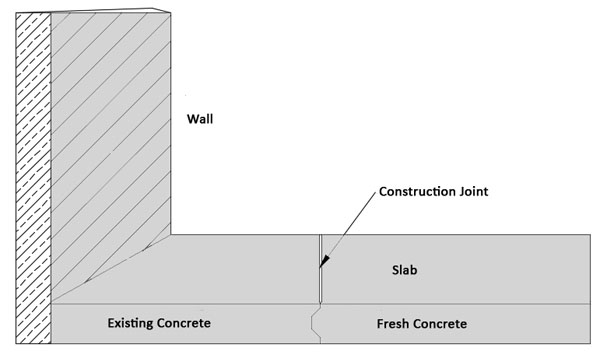

Construction Joints

Joint made when fresh concrete is placed against hardened concrete due to work constraints.

In many structures, construction joints are made to accommodate the construction sequence of concrete placement. Of course, the amount of concrete that can be placed in any operation is dependent on the mixing capability of the batching plant and the available time.

After a certain time interval, there would be a break in concrete supply and then it would start again. During that break already placed concrete would get hardened. After the break, the wet concrete would again be placed on hardened concrete.

In this regard, a construction joint is a separating plane between the already placed concrete and the wet concrete batch.

Expansion Joints

Joint made to take care of the expansion of concrete subjected to higher temperatures.

The concrete expands its volume due to an increase in temperatures. Concrete expands to about 10 millionths per degree Celsius. Although this expansion is very small. But in large volumes of concrete like in bridges, pavements, etc., the expansion would be significant.

If the concrete is not freely allowed to expand, the stresses due to temperature variation would not be relieved. As a result, cracking would be developed.

To allow free movement of concrete, joints are made at several locations by providing a gap. These joints are called expansion joints and allow the free movement of concrete under expansion.

Expansion is a function of length. Concrete structures which are usually longer than 45 m would require one or more expansion joint.

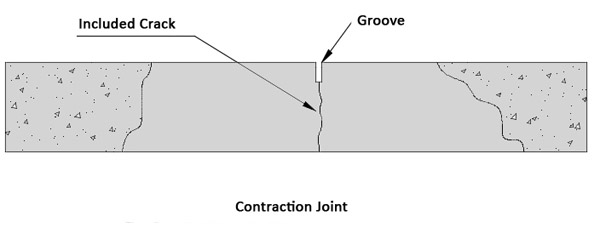

Contraction Joints

Joints are made to cater to the shrinkage of concrete while drying and hardening.

Like expansion, concrete also experiences contraction due to a reduction in temperatures. Tensile stresses result from drying shrinkage and ambient temperature drops in restrained concrete elements that are prevented from contracting.

To overcome cracking caused by these tensile stresses, joints are placed in concrete in predefined locations to accommodate displacements due to contraction.

A contraction joint is sawed, formed, or grooved in a concrete.

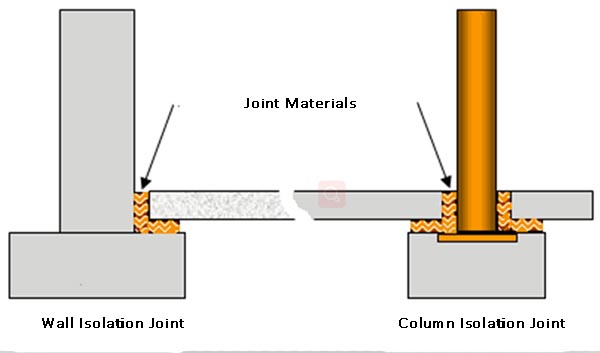

Isolation Joints

Joints are made to separate two concrete elements to avoid adverse loading.

Isolation joints have one simple purpose, which is to isolate a slab or concrete element from something else like a wall or a column or a drainpipe. This due to the fact that different structural elements would have different displacements due to shrinkage or expansion.

If the structural elements are connected, as one will contract or settle, the other may provide restraint, which will usually cause cracks.

Decorative Joints

All previously mentioned types of joints are used for structural purposes. On the other hand, decorative joints are used for aesthetic purposes. They can be made by scoring or saw cutting through the concrete surface.

For aesthetic purposes, the cuts made within the concrete should be only 1⁄4-inch deep. However, to serve their function, they must also be about 25 percent of the depth of concrete elements like a slab.

How to Make Joints

Construction Joints

- Construction joints should be preplanned at such a location avoiding maximum shear and flexure.

- Joints should be well masked to avoid an ugly appearance.

- The top surface should be roughened for the subsequent pouring of concrete to develop a proper bond.

- The existing surface of concrete may be clean, roughened, and treated before placing new concrete.

Following two steps are followed to make construction joints.

1. Cleaning the Surface of hardened concrete

- Wet- or dry-grit sandblasting

- High-pressure water blasting

- Mechanical removal by scabbier, or grinding wheels

- Power brooming and vacuuming

2. Apply Topping

- Cement- sand grouting is prepared.

- A latex bonding agent is mixed with cement sand grout and spread on the surface.

- An epoxy bonding agent is placed on the surface of existing concrete

After following the previous two steps, the new concrete is poured. In some cases, a tie bar is also provided, in the unreinforced concrete elements to prevent the opening of the joint.

Contraction joint

Typically, four methods are commonly used to create contraction joints in concrete surfaces: forming, tooling, sawing, and placement of joint formers

1.Formed Contraction Joints

Joint formers are used to create contraction joints. Joint formers can be made of either rigid or flexible material. Basically, they are plastic strips in T shape, which are place in the concrete during casting usually with a cutter.

2.Tooled Joints

These joints are tooled into the concrete surface during the finishing operations. A groove is formed to cause a weakened plane, which controls the location of the developing crack. Grooving tools with blades 1-1/2 to 2 in. (40 to 50 mm) in depth are used.

3.Sawed Joints

As with tooled joints, saw-cut grooves should be made at least 1/4 the depth of the member. Various types of sawing equipment and techniques are available, including diamond-studded blades and abrasive blades.

Expansion joints

Expansion joints are formed similarly to contraction joints. They can also be either grooved, formed, or sawed into the concrete.

Isolation joints

Isolation joints are usually made by inserting joint material next between the interface of structural elements. That interface could be either between a column or wall to a pipe and slab. The joint material is usually asphalt-impregnated fiberboard/ Additionally, plastic, cork, rubber, and neoprene can also be used. The depth of the isolation joint should go all the way to the depth of the slab or other structural elements.

Decorative joints

Decorative joints are my either scoring or saw cutting. Scoring is done with a groover tool when the concrete is fresh. Score lines can be cut straight, but also may be done diagonally to the edges. Conversely, saw cuts are accomplished when the concrete is hardened. Geometric shapes can be saw-cut into the slab and then stained to create a contrasting look.

What to Fill Joints (Seal,Caulk)

Joints are filled to achieve liquid tightness, which will allow structures to maintain their long-term integrity. A joint sealant is usually made of high-quality rubber or plastic.

Construction joints

The filling is done to the full depth of the joint. The filler material must have enough compressive strength to support the edges of the joint from stresses imposed by surrounding structural elements.

Contraction joints

They are commonly filled with100% solids epoxy filler or polyurea filler

Expansion joints

They are commonly filled with a compressible fiberboard material.

Isolation joints

In order to have a cleaner isolation joint, the top part of the joint material is removed and filled with an elastomeric sealant.

Decorative joints

Sometimes decorative joints are filled with different colorful vinyl’s are used for aesthetic purposes

How to Repair Joints

A damaged joint can be repaired by following these steps:

- Prepare the surface using the grinder to abrade the edges of the joint

- All the dust and debris should be removed

- Abrade the edges again with a pole sander

- Put a wooden piece in the longitudinal direction of the joint.

- Cement- sand grouting is prepared

- A latex bonding agent is mixed with cement sand grout and spread on the surface.

- An epoxy bonding agent is placed on the surface of existing concrete

- After the grout is dried, the wooden piece is removed

- Lastly, the joint is rubbed with a pole sander again to have a smooth surface.

Conclusion

To conclude, several types of joints are made in concrete, which can serve both structural and aesthetic purposes. A range of joint making technologies are available ranging from saw cutting devices to grooves and joint molds.

Lastly, joints can be filled with a range of materials including plastics, rubbers, epoxies, and even fiberboards.

Can you please send me the other materials that can be used for concrete joint. Pics if possible.

thanks for your comments