Steel Bar Cutting Machine: One-Stop Guide As You Need

You have either bought the steel bar cutting machine or you intend to buy it.

This is a one-stop guide for all knowledge related to the steel bar cutting machine. We will talk about the types of rebar it cuts, the different sizes, cutting time, and the details of the motor.

We will also discuss its working principle, available spare parts, pricing, precautions and alternatives.

Contents

What Kind Bars It Cuts

The bar cutting machine cuts all sorts of steel bars. Its heavy machinery and build allow it to be used for different kinds of steel bars. Different variations of the machine have different limitations in type and size.

Some different types of steel used are:

Round bars:

It is a long and cylindrical metal bar that has numerous industrial uses. Its most common use is in shafts. They are not used in RCC since it will not provide any friction to the concrete.

Its different types are hot-rolled steel, cold-rolled steel, and stainless steel.

The GQ40 variation of the bar cutting machine can cut a minimum diameter of 6 mm and a maximum diameter of 40 mm.

The GQ45 can cut a minimum diameter of 6 mm and a maximum diameter of 45 mm.

Lastly, the GQ50 can cut a minimum diameter of 6 mm and a maximum diameter of 50 mm.

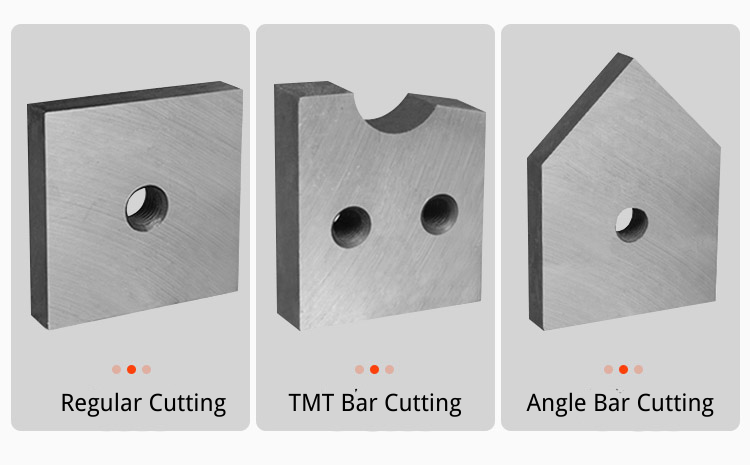

TMT bars:

Thermo-Mechanically Treated bars are the most used rebars in construction. They are reinforcement bars with high strength. They have a hard outer core and a soft inner core.

They have ribs or their outer surface to provide friction and form a strong bond with the concrete.

The GQ40 variation of the bar cutting machine can cut a minimum diameter of 6 mm and a maximum diameter of 32 mm.

The GQ45 can cut a minimum diameter of 6 mm and a maximum diameter of 36 mm.

Lastly, the GQ50 can cut a minimum diameter of 6 mm and a maximum diameter of 40 mm.

Flat bars:

Flat bars, also known as rectangular bars, are long and rectangular shaped. They are used in manufacturing support materials. For example braces, overhead doors, and frame structures.

Some types are hollow inside and prove to be very cost-effective. Its most frequent use is in steel structures.

The GQ40 can cut a flat bar with a maximum dimension of 70 mm in breadth and 15 mm in height.

The GQ45 can cut a flat bar with maximum dimensions of 70 mm in breadth and 15 mm in height.

Lastly, the GQ50 can cut a flat bar with maximum dimensions of 80 mm in breadth and 18 mm in height

Square bars:

They are also a type of rectangular bar but with equal dimensions. They are mostly used for manufacturing and repairs.

Square Bar can be in all types of metal: from cold-rolled steel and aluminum to brass, bronze, copper, and more.

The GQ40 can cut a square bar with maximum dimensions of 32 mm in breadth and 32 mm in height.

The GQ45 can cut a square bar with maximum dimensions of 32 mm in breadth and 32 mm in height.

Lastly, the GQ50 can cut a square bar with maximum dimensions of 40 mm in breadth and 40 mm in height.

Angle bars:

Angle bars, also called L-brackets or angle iron, are metal bars in the form of a right angle. These can be used to provide additional strength and stability in supporting beams.

It can also protect them from corrosion by covering the corners and sides. A more informal use for it is as a wall-mounted shelf.

The GQ40 can cut a square bar with maximum dimensions of 50 mm in breadth and 50 mm in height.

The GQ45 can cut a square bar with maximum dimensions of 50 mm in breadth and 50 mm in height.

Lastly, the GQ50 can cut a square bar with maximum dimensions of 63 mm in breadth and 63 mm in height.

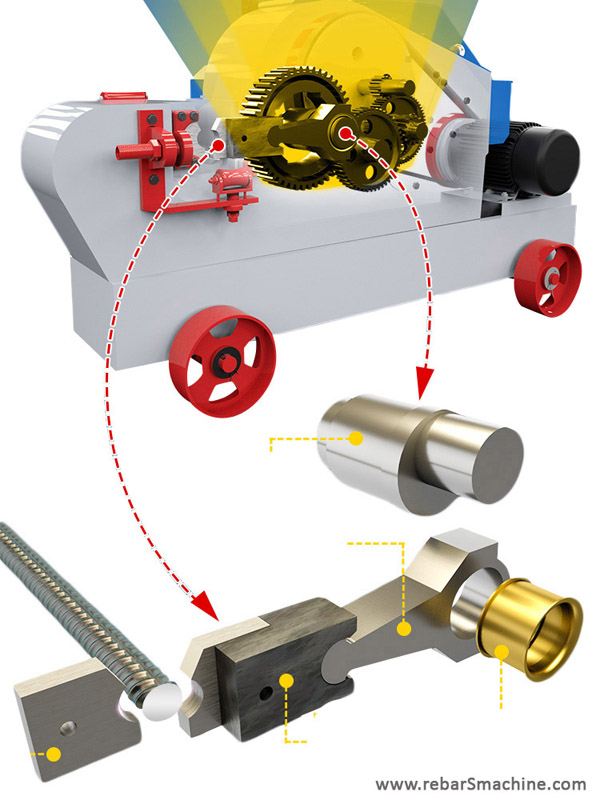

Working Principle

The machine can be described as semi-automatic. It works on the principle of pulleys, gears, and electric motor.

It consists of a strong electric motor. The electric motor is connected to a large pulley through a V belt. The electric motor makes the pulley move. The pulley then turns several connected gears inside the machine.

The resulting torque drives the crankshaft. The crankshaft then drives the connecting rod to move the cutting blade.

One blade is fixed while the other blade is moveable. The bar to be cut is placed in between them. The force generated by the motor is so much that the blades can cut the rebar in two.

This mechanism is also called Grip and Slice. The U-shaped support between the blades grips the bar.

The moveable blade then moves from its slot and presses on the bar. This cuts the bar cleanly at the point of contact with the blades.

Spare Parts

Is the machine acting rusty? Is it performing slow? Do you think you might have to buy a new one? Well, have no worries. The spare parts for this machine are available. The major spare parts that can be replaced are:

- Windings

- Connecting Rod

- Crankshaft

- Motor

- Alloy blades

Price

The basic price of the machine is the same for all regions. But the final price of the machine depends upon factors like shipping charges, no. of units, and customs duties.

For expmaple, if you are a buyer in Pakistan or India

The price for any model ranges from PKR 1.65 lac to PKR 2 lac in Pakistan.

Meanwhile in India, the price ranges from INR 75000 to INR 1.1 lac.

| Country | Lower | Higher |

|---|---|---|

| Pakistan | PKR 1.65 lac | PKR 2 lac |

| India | INR 75000 | INR 1.1 lac |

Safety Checklist

Using heavy machinery at a construction site can be dangerous. So you should keep a couple of things in mind before starting the process:

- Stand at least 2 feet away from the machine when operating it

- Use gloves to handle machinery and bars

- Make sure to keep all wires covered

- Keep your hands away from the blade

- Adjust the cutting clutch to your desired length.

Alternates

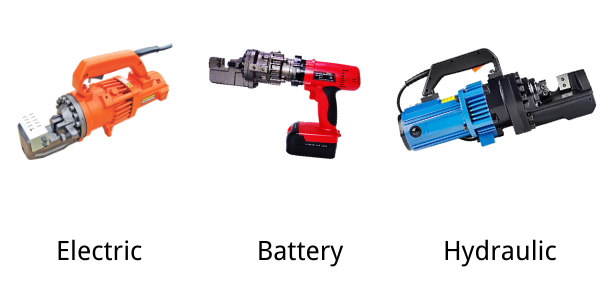

In case of a short budget, less working space, or less manpower, an alternative is the portable steel bar cutter. It is small, easy to carry, and relatively less expensive.

It comes in different types.

Some work on electricity, some on battery, and some are hydraulically operated.

Leave A Comment