How to Use Concrete Mixer [Continuous & Batchs; Drum Mixer & Pan Mixer]

One of the fastest way to produce concrete is through concrete mixers. Concrete done by hand mixing may be the cheapest but laborious therefore for medium to large projects, concrete mixer is the key. Concrete done through concrete mixers does not only have an advantage of being lesser labor or supervision but can also produce concrete with good uniformity.

It is well known that the quality, workability, strength and durability of concrete is not only dependent to the ratio of your concrete but with how consistent your mix is.

We can categorize concrete mixer into two types according to its working principles wherein each type will have its different ways of using:

- Continuous Concrete Mixer

- Batch Concrete Mixer

Contents

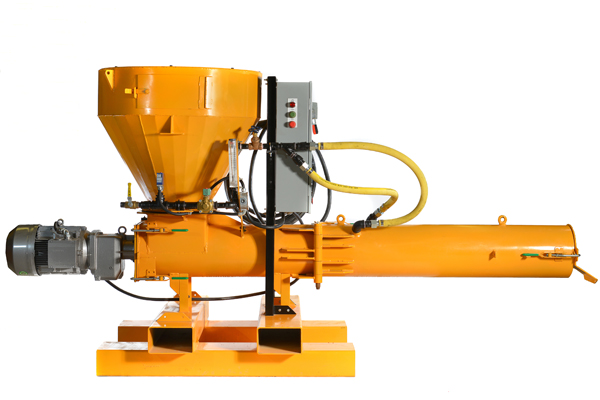

Continuous Concrete Mixer

Continuous concrete mixer is a process wherein the raw ingredients like cement, fine and coarse aggregates, admixtures and water are continuously being fed or loaded by a screw feeder and are mixed into the drum and are discharged continuously and simultaneously until the concrete job is achieved or until the work break occurred.

Usually, continuous concrete mixers are set up on the construction site itself so the concrete process works with no delay or interference and that the concreting works will be continuous, as its name suggests.

Continuous concrete mixers are usually seen on large-scale construction projects like bridges, dams, etc since these types of structures demands large masses of concrete which requires higher possible productivity of concrete.

How to use continuous concrete mixers

Since continuous concrete mixers are made for higher production of concrete, everything is run by big equipment. The key part of the continuous concrete mixer are the on-tilting drum with screw-type blades.

As the raw ingredients are being fed by a screw feeder, the materials are rotated axially and radially by the mixer vessels which follows a zigzag pattern and in constant motion.

The movement of the concrete to the discharge point is through retention time of the mix which occurs by adjusting the fed rate, mixer speed and mixer design.

Batch Concrete Mixer

From the name itself, batch concrete mixer is a process of mixing raw ingredients of concrete like cement, fine and coarse aggregates, admixtures and water by batch on scheduled time and is discharged batch after batch. Batch concrete mixers can be done in two ways which depends on the axis of which the mixer is rotated. These two types are:

- Drum type mixer – which is rotated in horizontal or inclined

- Pan type mixer – which is rotated in vertical

Both type of batch concrete mixer have blades or baffles inside which the drum or pan are rotated at a certain velocity and angle depending on what type it is.

Drum type mixer

Drum type mixer consist of double conical shape drums wherein each have its own purpose. One of which is responsible for the lifting of the raw ingredients as the drum rotates on its axis. The drum type mixer is further classified according to the shape of the drum, the angle of the drum’s rotation, the sizes of the blades and the angle of the blades. With this further classification, the three type of drum type mixer are:

- Tilting drum mixers

- Non-tilting drum mixers

- Reversing drum mixers

Tilting Drum Mixers

Tilting Drum Mixers are concrete mixers that are conical or bowl-type in shape which can be inclined or “tilted” in various angles in reference to the x-axis. Tilting drum mixers are more applicable for concrete mix that requires lesser workability and those that contains large-sized aggregates which are greater than 7.5 cm.

Since tilting the drum in full zero degrees with the x-axis required more energy in the mixing process, it is suggested to keep the angle at 15 degrees to achieve the right consistency of the concrete mix and will not segregate or causes the concrete to stick at the bottom of the mixer.

Non-tilting Drum Mixers

Non-tilting drum mixers are in fixed position whether inclined or full horizontal which means that it is not capable of being tilted in different angle, but only on its fixed position.

Since it is non-tilting, the drum of which the raw ingredients are being mixed can be opened on both ends allowing the materials to be poured down on one end (which usually is the top) and the other end is the chute where the concrete is collected or released on the other.

Since this type does not allow rapid discharge, it is more applicable with concrete mixes which aggregates have lesser than 7.5 cm as it lessens the possibility of segregation. Usually for mixes that have smaller aggregates, it is more appropriate for smaller scale.

Pan Type Mixer

Pan type mixers are in circular pan shape which the raw materials are being mixed by the set of blades inside of the pan. This set of blades are usually arranged in star shape to allow all the raw ingredients to be incorporated well and have specific blades that are responsible of scraping the materials on the side of the pan to avoid sticking.

The pan type mixer can have two unique method. One of which is that the pan is fixed and the blades inside rotates in vertically and the other method is where the blades are in static position and the pan rotates in vertical axis.

The pan type mixer is more results are more efficient and the produced concrete is being collected in the central hole in the pan.

How to Use Batch Concrete Mixers

Even though there are different type of concrete mixers, the steps in using batch concrete mixers are general and are applicable in different type.

Wear Your PPEs And Other Gears

Since we are dealing with equipment that are run by engine and that our raw materials are very small, protective gears are required to avoid inhaling or hurting our eyes. Wear your PPEs like and not limited to rubber gloves, eye wear and particle mask.

Set Up Your Concrete Mixer And Gather Your Ingredients.

In setting up your concrete mixer, always make sure that it is placed in an even surface and set your mixer in its upright position. Gather all the raw materials like cement, fine and coarse aggregates, admixtures and the required amount of water.

Turn On Your Engine

Once everything is ready. Turn on your engine, open your fuel tap and make sure that your choke is fully closed. Once your engine is in its required velocity you may now proceed to the next step.

Pour Out Your Dry Ingredients With Initial Water

You can start pouring out all of the dry ingredients like cement and aggregates but with more or less half of the required quantity of water. Not pouring all the water is to avoid overmixing the concrete.

Add More Water (If Necessary)

Now that your raw materials are being mixed in your concrete mixer, you can now add more water if necessary to achieve the paste consistency of the concrete. Depending on the type of your concrete mixer, the concrete can be fully mixed within five minutes.

However, if there are any dry area, chunks or your concrete is not uniform, add more until the desired consistency is achieved.

Conclusion

To achieve the right consistency of your concrete, always make sure that you are using the applicable concrete mixers with your dry ingredients. Different concrete mixers are not required but are suggested and are made to make it easier for us to achieve the uniformity of the concrete.

Leave A Comment