What Is Floor Scarifier And How To Use It

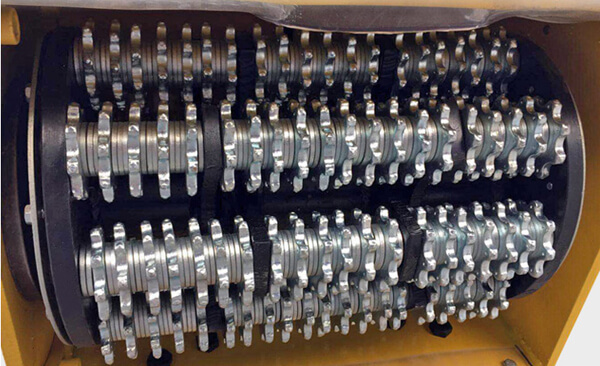

Scarification utilizes steel or carbide star-shaped cutters mounted in rows around a rotating drum. There are several types of cutters available for various applications.

Using this drum machine, up to 2 inches can be removed in one go. Road construction is where scarifiers are most commonly found. Pavement traffic lines can be removed, high spots can be ground down, and the surface can be grooved.

In the removal of old coatings and resurfacing, scarification is extremely effective. In this article, we will discuss what is scarifier, how it works, where you can use it how to use it.

Contents

What Is A Floor Scarifier

Scarifiers, also known as surface planers or milling machines, use rotating tools to cut or scar the surface of the concrete. Because the cutting wheels rotate at very high speeds, scarifiers remove concrete faster and more aggressively than grinders.

Concrete is chipped away by these cutters leaving rough surface profiles for various purposes. Some models are capable of removing up to 1/4 inch of material in one pass, and cutting depths are adjustable on most machines.

How It Works

A removable drum mounts the cutting wheels or flails. Models differ in the number of cutter shafts per drum, but generally, machines with more shafts can hold more cutters per loading for increased scarifying action and higher production rates.

A variety of styles of cutters are available to suit various applications, and they are made of tungsten carbide or hardened steel. Variations in diameter, width, number of cutting teeth, and tip style (e.g. flat, sharp, or angled) can produce vastly different results depending on the floor material and final profile desired.

What Does A Scarifier Do To Concrete

Their cutting wheels (made of tungsten carbide or hardened steel) are mounted on a removable drum and rotate at very high speeds in order to cut, plane, or scar the surface. As these cutters or flails constantly pound the surface, small chips of concrete are broken away to produce a rough profile. By impacting the surface vertically, the cutters can reduce any high spot or lip to the lower level of the adjacent floor.

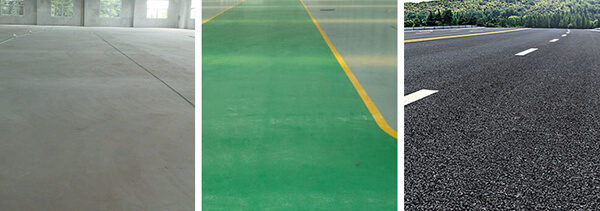

The number of cutter shafts per drum varies from machine to machine, but generally, the more shafts a machine has, the higher its production rate and scarifying action. Depending on the cutter assembly used, different profiles can be created. According to the requirements of the application, surfaces can be left smooth, textured, or roughed up.

When Should You Scarify Concrete

The scarifier is used for removing coatings (such as mastics, rubbery adhesives, or epoxy), grooving sidewalks and walkways, and leveling misaligned concrete joints and uneven surfaces.

Scarifiers are a good choice when:

A CSP of 4-5 is necessary

These Concrete Surface Profiles (CSP), developed by the International Concrete Repair Institute (ICRI), are divided into ten classifications of surface textures according to distance from the peaks of the surface to the valleys.

The way in which a scarifier “cuts” a floor is by using Tungsten Carbide cutters or flails. These flails act like little hammers that continuously hit the concrete and break away small pieces. The result is a very rough profile that is required by some coatings to bond properly.

There is a need to remove more than 1/4″ of concrete

Since the flails are used to break away concrete chips, uneven or rough floors are quickly and safely impacted down. The highest points of a slab are often near construction joints or cracks, so a scarifier is perfectly suited to attack any high spot and reduce it to the adjacent low spot.

Additionally, scarifiers can perform a wide range of tasks with interchangeable cutting wheels and drum setups. Examples include:

- Removing coatings (including heavy mastics, rubbery elastomeric, and epoxy)

- Milling (light or heavy)

- Making walkways slippery by grooving them

- Removes trip hazards from sidewalks

- Levels uneven surfaces and misaligned joints

How To Use A Floor Scarifier

Following steps should be followed to operate the scarifier:

- Hook up the scarifier in the correct voltage socket and make sure the current is being supplied. If you have a gasoline model check how it can be fueled.

- Slowly lower the cutter head to the slab surface using the cutter head lever and then rotate the depth control down until your head cutter touches the slab.

- After the contact has been made, lower the machine by 1/8” additionally. If you try to cut beyond this limit, it might cause damage to the machine and drum itself.

- Along with the scarifier, use a vacuum system. Water can also be used to settle down the dust.

- Start cutting in passes. If you move it at the right pace, the machine can cut the material. According to the size, weight, horsepower, and hardness of the material, a machine’s speed will be determined. If you push the machine too fast, it will skim over the surface. The self-propelled planer should not be allowed to walk away from you if you keep an eye on it. When the cutter is running, it should never be stopped.

- A first pass should be made from north to south, and a second pass from east to west. As a result, the material is removed evenly to depth while compensating for surface differences in height.

- To stop cutting, move the cutter head control lever to raise the cutter head assembly above the slab surface.

- For gasoline and propane-powered engines, close the throttle and turn the ignition switch to the off position. For an electric model, simply press the OFF button.

- After cutting clean the entire machine and let it cool down. Check for any worn or damages to cutters and perform the required maintenance.

- If water was used to settle down the dust, clean the slurry underneath the machine before it dries down.

Conclusions

Steel or carbide star-shaped cutters are mounted in rows around a rotating drum for scarification. Scarifiers, also known as surface planers or milling machines, cut or scar concrete’s surface using rotating tools.

Using tungsten carbide or hardened steel cutting wheels mounted on a removable drum, they cut, plane, or scar surfaces at high speeds. The scarifier can be used to remove coatings (such as mastics, rubbery adhesives, and epoxy), groove sidewalks and walkways, and level misaligned concrete joints and uneven surfaces.

Leave A Comment