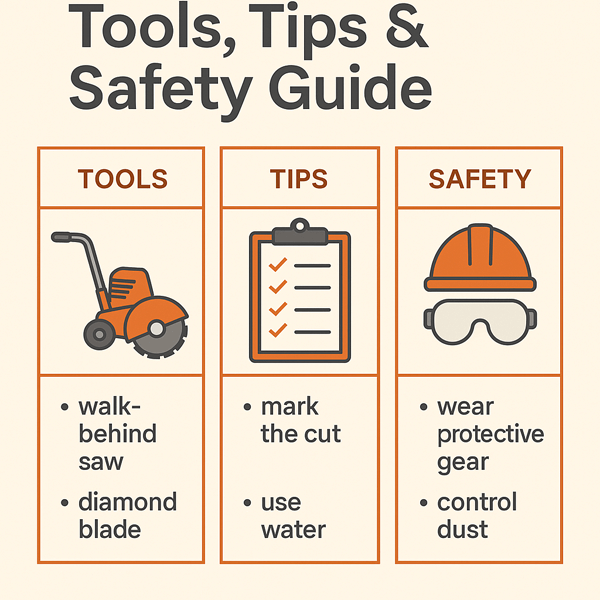

Best Way to Cut Asphalt: Tools, Tips & Safety Guide

Asphalt demands cutting as it can be needed in repairs or works on utilities. It can also be required for correction of the driveway, and road construction.

Asphalt removal poses some challenges regardless, the project size. These are handing dusts, heat, irregular cuts and safety issues.

This guide will explain how to cut asphalt in the best ways to do it. We will discuss the tools required, how to prepare and how to cut. Also, we will describe key safety tips and errors to be avoided.

Contents

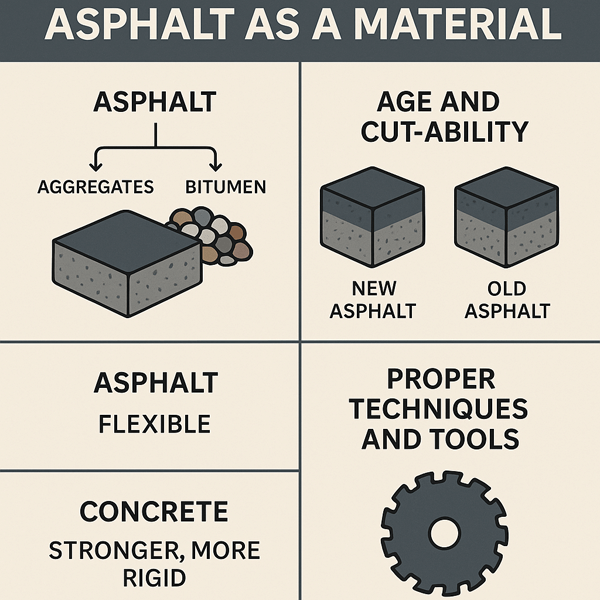

Understanding Asphalt as a Material

Asphalt is an aggregate-bitumen mixture. The bitumen is a sticky material that holds the aggregates (sand, gravel and stone) together. Old and thick asphalt surface may penetrate the asphalt cut-ability.

The new asphalt is much softer as compared to the old asphalt which is harder to cut through the outer surface. Concrete differs with asphalt in the manner it cuts. Concrete is normally stronger and sturdier, whereas asphalt is flexible.

This provides the added advantage of being able to cut asphalt easier. Although it does not mean that you should not take the right techniques and tools.

Choosing the Right Tool for Cutting Asphalt

The selection of the proper tool to cut asphalt varies according to the size of the project and projects. Now we are going to examine the most popular tools:

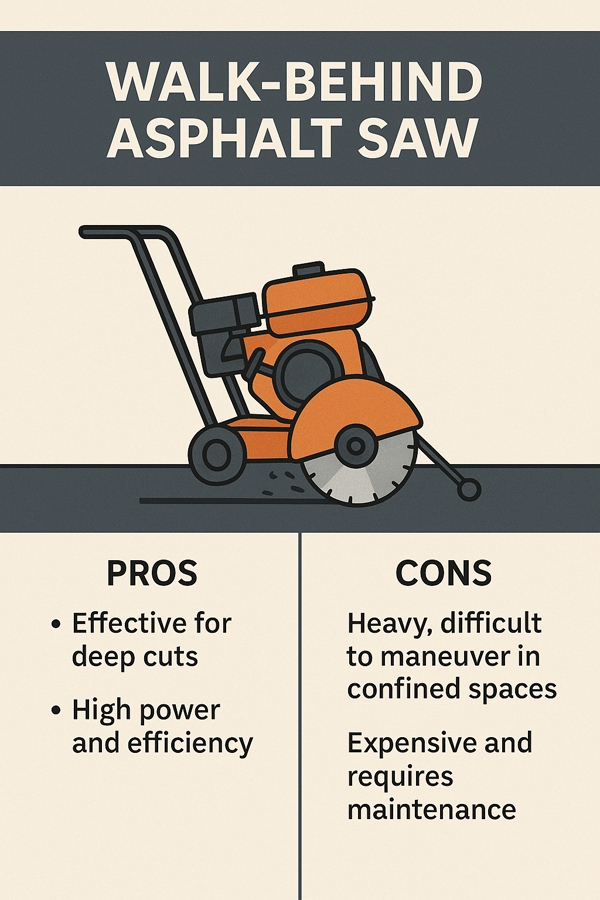

Walk-Behind Asphalt Saw

These saws work best in large; or deep cuts. They can be suited on roadwork, parking plazas, and big driveways. The walk-behind saws are generally heavy but they are also capable of workload.

Pros:

- This asphalt saw is effective for deep cuts.

- It possesses high power and gives good efficiency.

Cons:

- It is heavy and difficult to maneuver in confined spaces.

- Walk-behind saw is expensive and requires maintenance.

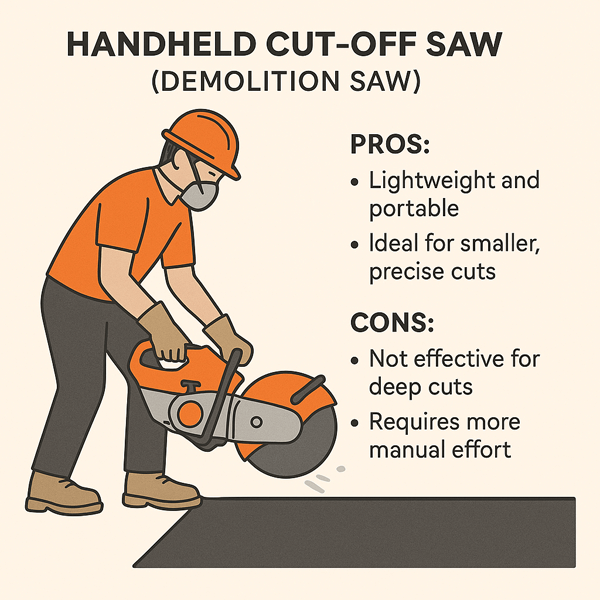

Handheld Cut-Off Saw (Demolition Saw)

Handheld cut-off saws do perfect job in case of smaller jobs or when utmost precision is required. These are lightweight and flexible saws. They come in handy in smaller cuts such as repairs on the driveways.

Pros:

- This type of saw is lightweight and portable.

- It is ideal for smaller, more precise cuts.

Cons:

- Demolition saw is not as effective for deep cuts.

- It requires more manual effort.

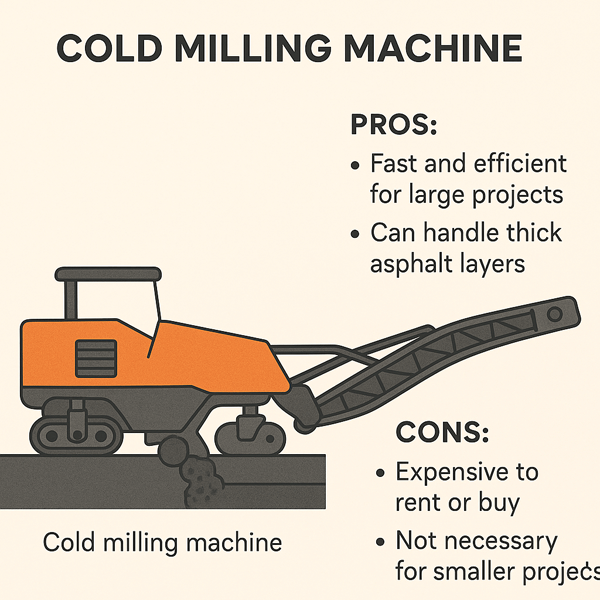

Cold Milling Machine

A large-scale removal of an asphalt is done by a cold milling machine. This machine can quickly grind down substantial asphalt layers. This characteristic makes it ideal for a commercial or municipal large-scale job.

Pros:

- It is a fast and efficient for large projects.

- Cold milling machine can handle thick asphalt layers.

Cons:

- This is an expensive machine to rent or buy.

- It is not necessary for smaller projects.

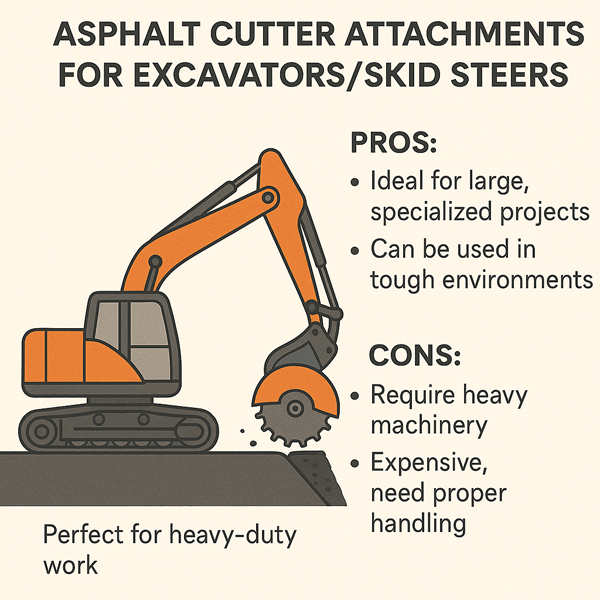

Asphalt Cutter Attachments for Excavators/Skid Steers

When specialized uses, asphalt cutting, an equipment is attached to a backhoe or skid steer. They are good when working on heavy loads where chunks of asphalt need to be chipped off in a short period.

Pros:

- This assembly is perfect for large, specialized projects.

- It can be used in tough environments.

Cons:

- This equipment assembly requires heavy machinery.

- These attachments are expensive and needs proper handling.

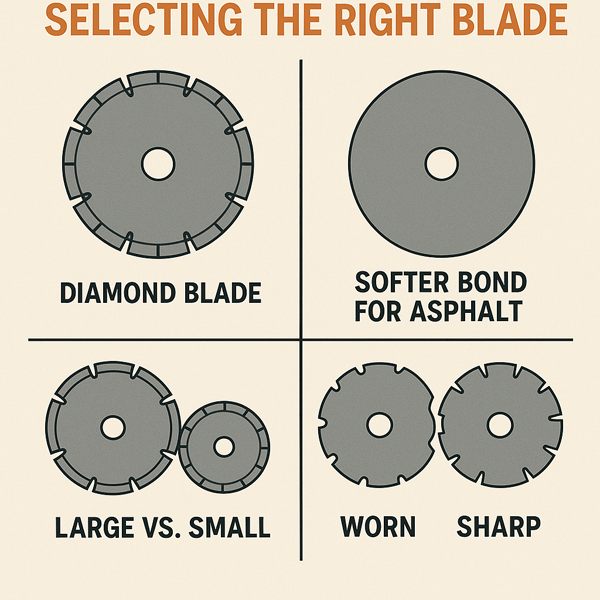

Selecting the Right Blade

There is so much to say when it comes to cutting asphalt and this is where one needs the right blade.

Diamond blades are vital in the cut through hard asphalt. Such blades are purpose-oriented. They can only be used on abrasive surfaces such as asphalt. It makes accurate cuts with little abrasion.

The softer- bonded diamond will perform better on asphalt. It gives the blade to retain its ability to cut.

Design of the blade is more crucial in size and segments. Big blades are well suited to deep cutting. Whereas small blades are suitable to precision.

Also, watch blade wear. A dull blade may create rough and jagged cuts and even break your equipment. Check the blade and make sure it is not worn, otherwise replace the blade.

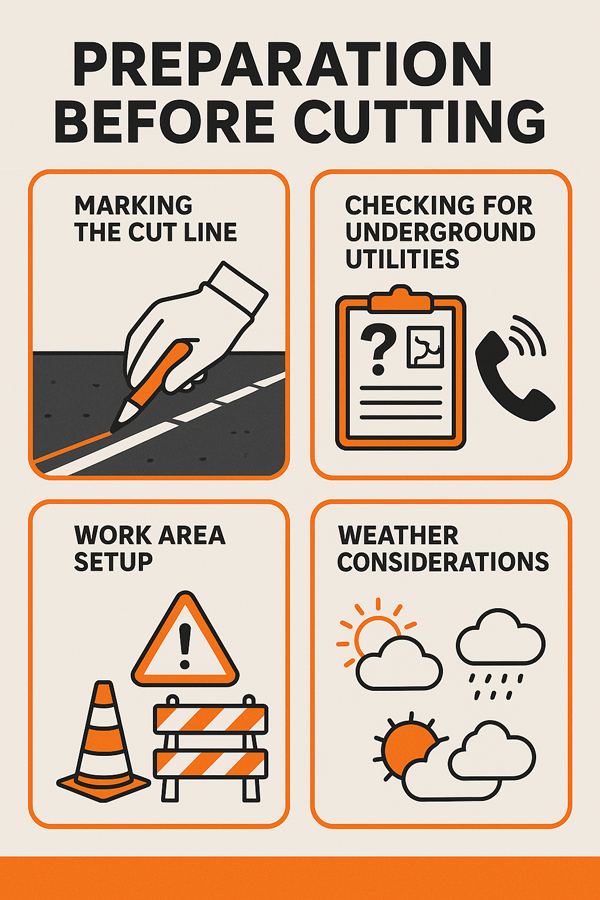

Preparation Before Cutting

Some preliminary work must be carried out before the process of cutting commences. It is necessary to ensure that the process is efficient and without any injuries. Here are the steps to follow during cutting process.

- Marking the Cut Line

Always start by marking the cut line accurately. For this purpose, use chalk, spray paint, or a snap line to make sure your cuts are straight and even.

- Checking for Underground Utilities

It is better to check for underground utilities before you begin. Calling the local utility service is a must before you dig or cut.

- Work Area Setup

Put up barricades, warning signs and traffic control as required. This ensures the safety of the workforce and the pedestrians.

- Weather Considerations

Weather plays a role in the cutting process. To carry out in hot weather, wet cutting to reduce the heat on the blade is recommended. When the weather is colder water cutting is normally preferable. However, you are to modify depending on particular requirements..

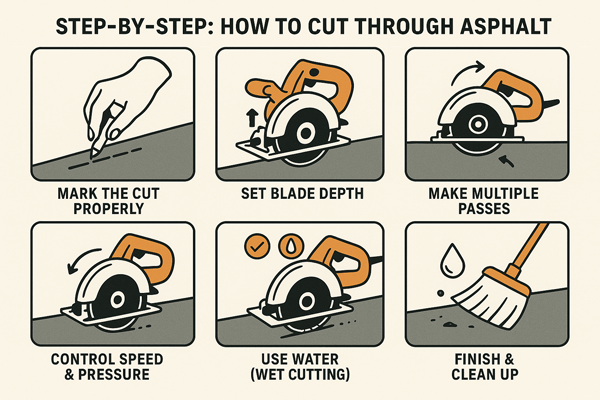

Step-by-Step: How to Cut Through Asphalt

So, let us do the cutting in steps.

- Mark the Cut Properly- Before placing the saw then mark the cut. Keep a snap line or chalk to assist with your cuts.

- Set Blade Depth- Set blade depth to 1/4- 1/2 the depth of the asphalt on the first pass. This helps prevent the blade from binding.

- Make Multiple Passes- It is better to make several shallow passes for required depth. Making a deep cut can cause problems. These may be wrong cut, safety risk etc,.

- Control Speed & Pressure- You should make a cut with a controlled speed and pressure. Rushing and forcing too much pressure to cut can ruin the blade. Maintain a constant speed and excess of power.

- Use Water (Wet Cutting) –Wet cutting is invaluable to both minimize the dust and cool the blade. This is particularly significant on health and safety grounds.

- Finish & Clean Up- When the cut has been made, tidy up and make the actual area and work safe.

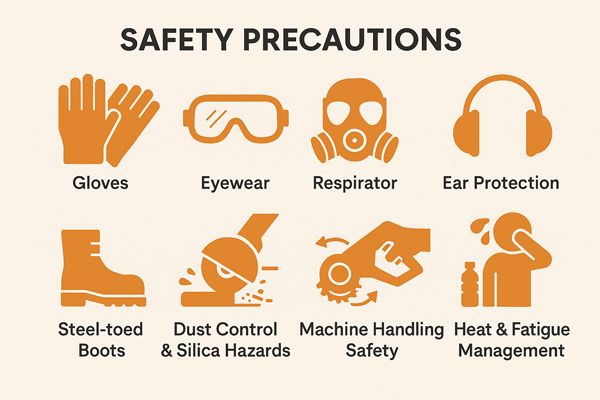

Safety Precautions

Safety is the priority in the process of cutting asphalt This is a protective gear check list:

- Gloves: These are required to prevent rocky surfaces interaction with hands.

- Eyewear: The eyewear or safety gogles shield eye with external objects hitting them.

- Respirator- It is required to stop inhaling heavy dust particles.

- Ear Protection- Hearing protectors prevent damage to your ears. It can control the issues caused by the high noise during the running of the machines.

- Steel-Toed Boots- Safety shoes are needed to prevent the dangers of heavy projections.

- Dust Control & Silica Dangers- Asphalt cutting involves fine dust. It may consist of silica that could be harmful to your lungs when inhaled. Wet cutting should always be adopted in order to cut down on dust and enhance good visibility.

- Machine Handling Safety- Power cutters and saws have the tendency of kick back. It is probable especially in case they are handled haphazardly. Maintain a straight firm grip on the machine at all times.

- Handling Heat/Fatigue- Asphalt work is often done in a hot sun. Fatigue is therefore the factor that makes one prone to witness an accident. Rest often under shade, have as much as possible to drink and be able to share the work.

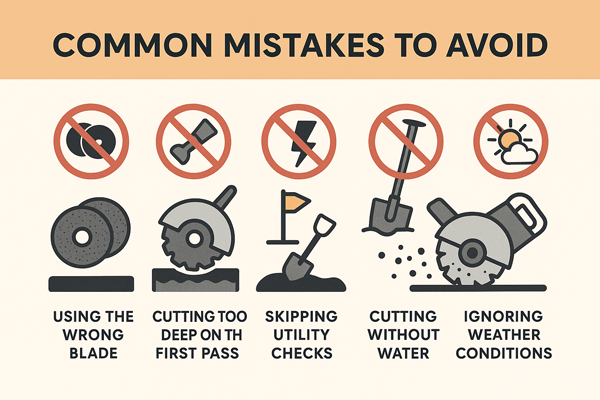

Common Mistakes to Avoid

To ensure a clean, efficient cut, some common mistakes are better to be avoided. Don’t do the following to achieve a clean efficient cut:

- Applying the Inappropriate Blade Type- You should use a diamond blade not an abrasive blade when you work on asphalt.

- Cutting Deep on the First Swing- Before attempting deep cuts, always have shallow cuts first.

- Never skip utility checks- Once you make a mark of where you want it, always check. You need to make sure that there’s no utilities in the ground.

- Cutting without water- Always use water for wet cutting when necessary. Cutting without water increases dust and heat during the process.

- Ignoring Weather Conditions- The wrong weather can affect cutting efficiency and blade performance. Plan accordingly.

After the Cut: Asphalt Repair & Finishing

When the cut is complete then repairs are needed. Clean up the cut ends so that they provide a close fit to patch with. You can repack the cut with fresh hot mix asphalt or cold patch, as you wish.

Proper compaction- Compaction should be in order to make repairs long lasting. Use the roller or the hand tamp to compact the fresh asphalt.

FAQs

Can I cut asphalt with a circular saw?

Yes, but only for shallow cuts. A circular saw won’t handle deep asphalt effectively.

What is the thickness limit in which asphalt can be cut without special equipment?

On a typical saw, the asphalt can cut up to 3-4 inches. Most standard saws can cut asphalt up to 3-4 inches thick. Anything thicker may require specialized equipment.

Should I use wet or dry cutting for asphalt?

Wet cutting is advisable to minimize dust as well as to keep the blade cool. Nevertheless, dry cutting is permissible under a cold weather regime.

Conclusion

It is not a small job to cut asphalt. But it can become a manageable work. For this, the tool tips, early preparation and safety is necessary to keep in mind. You must select the right blade. Make multiple passes and prioritize safety. These are essential to make a clean, efficient cut. These tips will help you in how to tackle any project involving asphalt cutting.

Leave A Comment