How To Straighten Rebar With 5 Tools [Pieces And Coils]

In construction, partially embedded reinforcing bars often need to be bent or straightened. It may be necessary to bend a bar due to incorrect fabrication, poor placement, or to facilitate access.

Straightening a bent bar might be necessary for any of the same reasons or if it was accidentally bent during construction. Let’s see how we can straighten the rebars and do we have any weakening caused by this straightening process.

Contents

Straighten Rebar Pieces

Manually straighten rebar

Manually straightening the bend bars is quite a labor-intensive task. Following steps are followed to straighten the bent bars.

- The first step is to tie all the bent bars together.

- Next, you should clamp all the bars to a fixed support.

- Note that clamping is done in the middle of bars at the point where bars are bent.

- The next step is to move bars in the opposite direction of the bent.

- More laborers might be required to rotate the bars depending on the number of bars being straightened.

- Bars are usually rotated by an angle of 180 degrees to get them straight.

Straighten rebar by the portable straightener

A portable straightener is usually powered by a battery or electricity. Following steps should be followed for straightening rebars with a portable straightener.

- Check the condition of the bending hook. Ensure that the bending hook is fully tightened.

- The rollers should be changed according to the rebar diameter.

- During cold weather, warm up the hydraulic oil for 30-60 seconds so that it reaches the appropriate viscosity. Pull the trigger-switch to extend the piston to its full stroke, and then switch to moving mode to retract the piston to its starting position. Perform this step 2-3 times without rebar.

- Straightening deformed rebar is the primary purpose of the tool. Straight rebar can also be bent with it.

- PUSH and PULL are the two modes of operation. By moving the lever on the mode control valve, you can select the desired mode. PUSH for piston advances and PULL for piston retracts. Press the switch to move the piston in either direction.

- Put the rebar between the bending hook and two rollers. The length of the rebar should be longer than the distance between two rollers to make sure it is properly positioned in the hook.

- To extend the bending hook, pull the trigger-switch.

- The rebar must be properly positioned in the hook and against the rollers.

- Once the rebar is fitted correctly, push it or pull it up to the desired angle to straighten it.

Straighten rebar by a rotate straightening machine

This method is used when you have either too many bars to be straightened or the length of the bar is long.

This machine has basically rotating clamps inside it which straighten the bars. Following steps are followed to strengthen rebars with this machine.

- The first step is to pile up large amounts of rebars that need to be straightened. Running the machine to straighten out only a few rebars is an inefficient process.

- Next is you start the machine. Usually, they are powered by electricity.

- The machine also needs to be clamped down the firm surface.

- Turn on the machine.

- Insert the bent rebars or stirrups or scrap steel from one end.

- The straight steel rebars will come out from the opposite end.

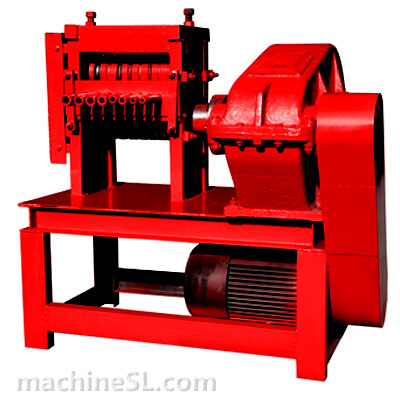

Straighten rebar by rollers opposite straightening machine

This machine is an even much better alternative for straightening rebars. It is best suited for coils. It has basically a huge roller installed in it, which compressed down the bar to make it straight. Following basic steps should be followed to operate it.

- Start the machine.

- There are insertion holes for the rebar. They are usually more than one. The diameter of the holes can also be adjusted in some models of the machine.

- Next is start inserting the rebar in the machine from one end. You do not need to push the rebar inside the machine. The roller inside the machine will basically pull rebar by itself.

- The straighter rebar or coil will come out from the other end.

- These machines are also good for rebar straightening assemblies.

Straighten Rebar Coils And Cut Them Into Pieces

In the previous section, we discussed several types of machines that can straighten the bent bars. Now let’s discuss a machine that can not only be straightened but also cut the rebar’s coils for several purposes.

Operation

This machine works in a similar manner to rotate straightening machines.

Specifically, the processing unit of the machine consists of a primary correcting part, which receives coil rebars in the unwound state, while simultaneously linearizing them by transversely pressing them from left and right; and a feeding part.

From the processing unit, the bar reaches the cutting unit, which is a place at the opposite end of the machine. It cuts the bar into the desired length.

Some salient features

- You can adjust the speed of straightening and cutting.

- You can also input the time for which you want to run the machine.

- The machine automatically counts the number of cutter rebars pieces it has produced.

- The machine has an interactive control panel for efficient operation.

Does Straightening Rebar Weaken It

Before we answer this question, it is vital to understand that whether bending a straight bar or straightening a bed bar, the bending operation is always involved. So the real question is will this bending action weaken the rebar and if it weakens, how many times we can apply bending operations on a bar?

Bars that have been accidentally bent can have various bend angles and bend diameters. Due to the unpredictable bending direction, the longitudinal ribs of the bar may be located at the neutral axis of the bend (weak axis bending), at the extreme fiber (strong axis bending), or at any intermediate location.

The weakening of a bar depends on the diameter of the bar and the temperature of the bar. Before we get into details, let’s see what the code says.

What Does The Code Say

The ACI 318 code says about it:

Reinforcement partially embedded in concrete shall not be field bent, except as shown on the design drawings or permitted by the Engineer

Adding on the commentary of this statement, ACI 318 says:

Construction conditions may make it necessary to bend bars that have been embedded in concrete, and it usually is not possible to provide a pin of the minimum diameter specified in the code at the point of the bend. Such field bending should not be done without the authorization of the inspecting engineer. The inspecting engineer must determine whether the bars can be bent cold without damage, or if heating is necessary. If heating is required it must be controlled to avoid splitting of the concrete or damage to the bars.

Will the bar weakens

- The small diameter reinforcing bars exhibit better bending and straightening performance than the large-diameter bars. So the lesser the diameter, the more frequently the bar can be bent.

- Large diameter bars could be bent at a temperature of 70° F to the ACI specified diameter around the weak axis without breakage. So the axis along which the bar is being bent or straightened also matters.

- Large diameter bars do not bend as much as 90 degrees at the ACI diameter around the weak axis could be field straightened at a temperature of 70° F without breakage.

- The breakage may occur at a slightly smaller angle when straightening is done at 30° F. So lesser the temperature more prone will be the bar to breaking or weakening. It can develop micro-cracks,

- Bending or straightening large diameter bars around the strong axis results in a greater incidence of breakage in the two deformation patterns in which the transverse lugs run into the longitudinal rib. Breakage is less likely in bends around the strong axis for the deformation pattern that tapered out before meeting the longitudinal rib.

- Heating the bars to 1500° F significantly improves the ability to bend and straighten large-diameter reinforcing bars. Bends as small as 5 in. diameter around the strong axis could be straightened without breakage.

Conclusions

To conclude, bar straightening is an essential operation required on construction sites. It may be necessary to bend a bar due to incorrect fabrication, poor placement, or to facilitate access.

Straightening a bent bar might be necessary for any of the same reasons or if it was accidentally bent during construction. We can straighten rebar using manual operations which are quite labor-intensive.

Alternatively, we can use electric portable rebar straighteners or rotating straightening machines, or rebar roller machines. The rebar roller machine is best for the coil. We can also cut the rebars with the same machine. Bending action involved in the straightening process weakens the rebar. The weakening of a bar depends on the diameter of the bar and the temperature of the bar.

Usually, the lesser the diameter, the more frequently the bar can be bent or straightened out. Similarly, the increase in temperature also improves bar straightening capabilities.

Leave A Comment