Can a Lawn Roller Really Compact Gravel? Here’s What You Need to Know

Compaction critical in construction and landscaping. In construction, compaction helps in creating stable soil bases to sustain the weight of structures. Strong and stable soils for vegetation growth in landscaping are also attained through compaction. The Lawn compactor is one of the most common compaction tools in landscaping.

A lawn compactor can be handheld or towed by a tractor depending on its size. The compactor utilizes the roller weight to compact loose topsoil, sod, and to flatten raised soil formations such as anthills. They come in different sizes depending on the required degree of compaction. Although they are meant for soil and grass, lawn compactors can be used to compact gravel. However, the effectiveness depends on the type of gravel being compacted

Contents

What is Gravel

Gravel is a construction material comprised of loose small to medium sized fragments of rock or other hard materials. Gravel can be created from typical rock or rare types such as granite and shell. There are several types of granite; classified based on size and source material. Common types of granite include;

- Pea gravel- This classification is based on gravel size. Pea gravel refers to particle sizes equal to that of peas. It ranges between 1/8 and 3/8 inches and is most applicable in decorative landscaping.

- River rock gravel- This is naturally occurring gravel found at the bed of rivers and other water bodies. The particle edges of river rock gravel are naturally rounded by the effect of water over time. It is commonly used in decorative landscaping and paving as the sizes range from pea-size to larger rock pieces.

- Crushed shell- This is an artificial type of gravel It is made by crushing sea shells to desired sizes. Crushed shell is popular as a paving and decorative material in coastal regions.

- Decomposed granite- This is a naturally occurring type of granite formed by weathering of granite over time. Due to its toughness, decomposed granite gravel is used in base construction for heavy structural projects. In some cases, it is used as a decorative material for landscaping projects.

Granite has many uses as a construction material and landscaping material. The uses depend on the size and toughness of the gravel particles. Here are some popular uses of gravel.

Structural uses

Gravel is used in construction for structural purposes in several ways. It is used in foundation bases to provide the soil with adequate strength to sustain building loads. In road construction, gravel is used in construction of subbase to sustain heavy traffic loads.

Landscaping and aesthetics

In landscaping, gravel is used as a decorative and/or structural material. Construction of walkways involve compaction of gravel to provide stable bases to support foot traffic. Decorative types of gravel such as crushed shell and river rock are used as surfacing material and wall decoration.

How Lawn Rollers Work

Lawn rollers are typically made of a cylindrical drum. The drum is made of either steel pr heavy duty plastic and is attached to a frame for pulling or pushing, depending on the roller type. While some lawn rollers are made of solid drums, some can be filled by sand or water to provide the weight needed for compaction.

There are several types of lawn rollers. The classification is based on the operation mechanism of the roller. Based on how the roller works, you may have the following;

- Push lawn roller- This is the most common lawn roller type. It is handheld and lighter than most lawn rollers. Push lawn rollers are best suited for small scale projects in fairly flat terrain.

- Tow behind rollers- This type of lawn rollers is commonly used for larger landscaping projects. The roller frame is attached to a tractor or truck then towed over the area under compaction. Tow behind roller is the heaviest and ideal for projects that require a higher degree of compaction.

- Spike lawn rollers– These lawn rollers have spikes on the drum that help to aerate the soil and break up compacted areas. They are ideal for use on lawns that have become compacted or for preparing a lawn for overseeding

Despite the type or lawn roller you choose, there are factors that should be considered for effective lawn compaction. These include;

- Terrain- How steep of flat the area under compaction is determines the choice of a lawn roller and end result of compaction. Using push lawn rollers in an uneven terrain is likely to yield poor results and cause extreme fatigue on the operator.

- Project size- The scale of the project should determine the size of lawn roller used. If compaction is to be done of a large area, tow behind rollers should be used. This helps with faster project completion and minimizes error due to fatigue.

- Soil moisture content- Too dry or too wet soils are difficult to work with. For effective compaction, the lawn should have moderate moisture to allow passing of the lawn roller. When the soil is too dry, particles cannot integrate, this affects the compaction process.

Compacting Gravel With a Lawn Roller

Although it is not the best tool for the job, a lawn roller can be used to compact gravel. However, the compaction results depend on a variety of factors. These include;

- Type and size of gravel- For effective use of the lawn roller, the gravel particles should be small enough to minimize movement when passed on by the roller. Pea sized particles are the best and easiest to compact using a lawn roller.

- Size of the lawn roller- Gravel is tougher than normal soil. To attain the needed compaction, you need a heavy lawn roller. This makes tow behind rollers ideal for gravel compaction.

The main concern while using a lawn roller to compact gravel is damage to the equipment. The drum is likely to be dented or broken especially when used on large gravel particles. In some cases, the roller might not attain the required degree of compaction due to its weight.

Alternatives to Using Lawn Rollers to Compact Gravel

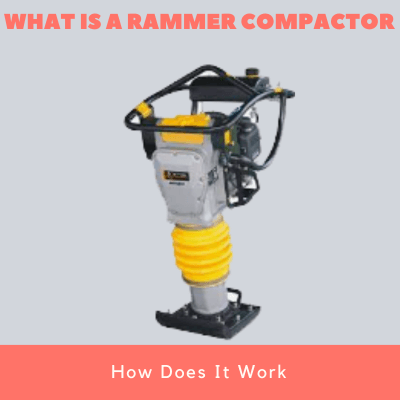

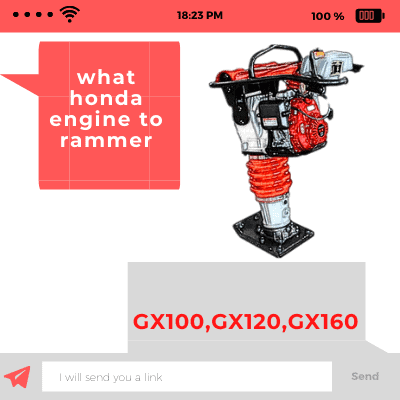

There are several other ways to compact gravel and attain good results. These include plate compactors, rammer compactors, and rollers. With plate compactors, the engine generated vibrations combine with the weight of the plate create enough force to settle gravel particles of any size. The up and down movement of the foot in rammer compactors drives the gravel particles to required compaction densities. With roller compactors, the vibrations and weight of the drum forces the gravel particles to settle.

With the above methods, it is easy to complete medium to large scale projects within a short time and attain the required compaction degree. The main disadvantage is that they require fuel or electricity to work. As a result, you spend much more compared to when using a lawn roller.

Conclusion

Lawn rollers are critical tools in landscaping. There are two main types of lawn roller; pushed and tow behind rollers. The selection of a roller depends on the scale of the project, terrain, and the required degree of compaction. Gravel compaction could be done using a lawn roller. However, this could damage the lawn roller since it is not the right tool for the job.

There are several alternatives to effectively compact gravel. These include using plate compactors, rammer compactors, and roller compactors. These are recommended for gravel compaction instead of using a lawn roller.

The lawn rolleris not as massive as it looks, so it is important to use it for its intended purpose to avoid injury. Although, in fact, it can handle gravel too.

Hi Fluix, thanks for your comments