12 Questions to Concrete Pavement Joints: Answers One By One

It is never too late to learn something different and unique. Likewise, when it comes to concrete pavement joints, there are several things that you should be well aware of.

Whether, you are a homeowner, property owner, or city worker. Here, you will be learning about 12 questions related to concrete joints.

Thereby, answers to these questions will help you make a suitable fit for the pavements

concrete pavement joints cutting machines

Choose a pavement joint cutter

Contents

What is a Concrete Pavement Joint?

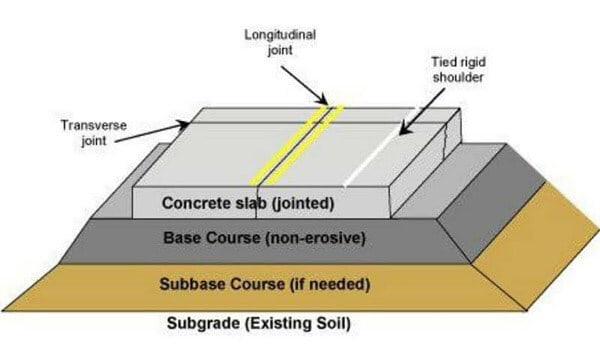

As it name suggests, it is used in concrete pavements. It helps them maintain their firmness and shape. Joints used in concrete construction mainly include construction, expansion, contraction, and isolation joints. They are placed in concrete slabs and pavements at regular intervals to prevent cracks in concrete.

Concrete pavement by their nature will crack sooner or later. The simple method is to saw cut pavement to create joints between the cracks. Pavement joints are strong to hold the area as they are designed and constructed directly into the cracks of the pavement.

How to cut pavement joint

Are Expansion Joints Needed in Concrete?

Expansion joints in concrete pavement are sometimes needed to adequately open the contraction joints. It helps to get an estimate of temperature for expansion.

Expansion Joint is made from an element that expands due to variations in temperature. If you construct a structure without placing an expansion joint, the sudden change of temperature will affect the adjacent structure. In fact, it would might ruin its entire shape.

What Material is used for Expansion Joints in Concrete?

Concrete expansion joints are quite vital to separate concrete and slabs from different areas, and the parts of the entire structure. These joints enable free mobility between the members of the adjoining structure.

It helps to minimize the uncertainty of cracking, when free mobility is restrained. After the concrete is placed, suitable tools are utilized to make inner channels in the poured concrete for setting the joint materials.

Material for Expansion Joints in Concrete

- Rubber expansion joint

- Fabric expansion joint

- Metal expansion joint

- Toroidal expansion joint

- Gimbal expansion joint

- Universal expansion joint

- In-line expansion joint

- Refractory lined expansion joint

What is A Transverse Joint in Concrete?

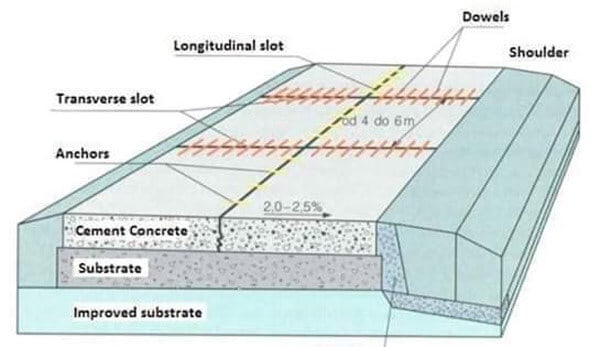

Transverse joints serve different purposes by running perpendicular to the length of the pavement.

However, it depends on the type of pavement being worked upon. Being sawed or shaped in a concrete slab, it creates an extension that goes upwards. Also, it enhances the location of cracking, which occurs as a result of the variations in slab dimensions.

Thus, making it the most basic kind of joint used on concrete pavements.

How Far Apart Should Expansion Joints Be in Concrete?

It is quite vital to place concrete expansion joints while installing concrete slabs. Since they enable a decent amount of room for a movement.

The recommended distance within expansion joints is between 10 feet or more. It should be set at least this near to assure that the concrete slabs do not crack or split into two.

However, this distance can get even lesser than 10 feet; it all depends, if you are working on a small one. Concrete expansion joints can be set at any particular distance within a slab.

Although the greatest distance is 10 feet from the slab’s end to an expansion joint.

How Many Types of Joints Are There in Concrete Pavement?

There are four different types of concrete joints based on their strength distribution.

- Construction Joints

- Expansion Joints

- Contraction Joints

- Isolation Joints

Do Concrete Slabs Need Expansion Joints?

It certainly needs expansion joints as all concrete will narrow and shrink slightly, as it dries down.

When it is placed, it will grow or contract depending on the suitable temperature. Expansion joints are utilized to enable the slab to shift and not put pressure on whatever it joins throughout the concrete.

It requires a little preparation before pouring; utilizing control joints and expansion joints. Moreover, it will reduce the risk of splitting, cracking, and extend the concrete’s lifetime.

What is The Standard Guideline for Spacing Contraction Joints to Space Them in Feet?

While constructing a contraction joint, you have to place a standard space. It should not be more than 2-3 times according to the slab’s thickness in inches. However, a slab of 4-inch slab needs to have a distance of joints 8-12 feet in total length.

The maximum suggested distance, connecting joints has been limited to two to three times the slab thickness, in inches. However, a 6 inches thick slab allows a maximum joint spacing within 12 and 18 ft.

How Do You Seal Between Concrete And Asphalt?

To seal between concrete and asphalt, you need to get a sealing gun with a tube of polymer-modified sealant. Simply, cut the tube end and install the sealant to fill the gap between the concrete and the asphalt.

Make sure to enable the sealant to dry overnight before driving or walking on the gap.

If you are facing a wider gap, then use a foam pipe to make the seal done. Foam pipe padding is covered with a thin layer of polyethylene that repels moisture.

Do Concrete Control Joints Need To Be Sealed?

Concrete control joints need to be sealed. Once the joint is cut into place, it will be left as seal or filled. However, the process of sealing should be done quickly to enable the joint to widen up.

The joint seal aims to prevent rainwater and dirt from getting in the joint. It also prevents intrusion from beneath the slab. However, a seal can further enhance the look of the floors and slabs installed.

How Do You Seal A Concrete Joint?

The concrete joint does not have to be completely clean to apply the sealant. You can remove the old sealant with the grinder as it will not conflict with the new sealant. You can apply the new sealant when the temperature is around 40-100F.

The perfect temperature is in center of the scale, as the joint will not entirely expand. It will take around 1 to 2 hours or 4 to 5 days to get a complete dried up surface.

What is A Joint Sealant in Construction?

From a constriction standpoint, a joint sealant is used for two purposes.

Firstly, it reduces the risk of both infiltration of surface water. Secondly, it compacts elements into the system of the joint. Joint sealants also decrease the potential for dowel bar corrosion by diminishing approach of deicing compounds.

Leave A Comment