Engine Tamping Rammer: The Essential Guide

Compaction is one of the critical processes in construction. It involves compressing construction material such as soil and asphalt to desired standards for load bearing. Compaction can be done by a variety of equipment. However, this article focuses on the engine tamping rammer and its significance as a compacting equipment.

An engine tamping rammer consists of a gasoline or diesel engine that drives a link mechanism up and down inside a tamper plate, delivering a forceful impact to the ground. This process helps to settle and compact the construction material, creating a stable base for further construction work.

Engine tamping rammers are commonly used in construction projects such as laying the foundation for buildings, paving roads and paths, and installing underground utilities.

The use of engine tamping rammers offers several benefits to construction projects. An engine tamping rammer is more efficient and effective than manual compaction methods, as it can compact a larger area in less time. Engine tamping rammers provide greater precision and control, allowing for uniform compaction across the entire project area.

Additionally, it reduces the physical strain on workers, as it does not require manual labor and can be operated by one person. This can lead to a safer work environment and reduced risk of injury.

Contents

How an Engine Tamping Rammer Works

Components of an engine tamping rammer

An engine tamping rammer consists of several key components, including a gasoline or diesel engine, a gear box, a tamper plate, and a guide handle.

The engine provides power to the gears, which in turn drives the link mechanism up and down inside the tamper plate.

The tamper plate delivers forceful impacts to the ground, compacting the soil or asphalt in the process.

The guide handle allows the operator to maneuver the tamping rammer and control the compaction process.

The operating principle of an engine tamping rammer

The engine drives the gears, this power is directed to a cylinder, causing the link mechanism inside the cylinder to move up and down.

As the link mechanism moves, it drives the tamper plate into the ground, delivering forceful impacts that compact the soil or asphalt.

The guide handle allows the operator to control the direction and depth of the impacts.

Types of engine tamping rammers

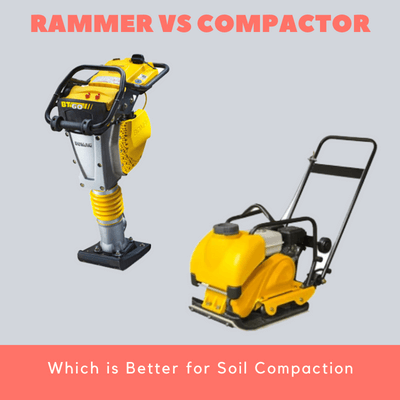

There are two main types of engine tamping rammers: Diesel engine tamping rammers and gasoline engine tamping rammers; these are discussed in detail below.

Gasoline engine tamping rammers

These are powered by gasoline and are known for their high mobility and versatility, making them suitable for outdoor use on various types of soil.

Diesel engine tamping rammers

Diesel-powered tamping rammers are strong and reliable, making them a good choice for heavy-duty projects and construction sites with limited access to electricity.

Applications of an Engine Tamping Rammer

Engine tamping rammers are versatile tools that are widely used in the construction industry, road building, and landscaping and garden design.

In construction

Engine tamping rammers are used to compact soil and asphalt for building foundations, laying pipes and cables, and paving roads and sidewalks. The tool’s ability to deliver forceful impacts and precise control makes it ideal for creating stable, long-lasting construction bases.

In road building

Engine tamping rammers are used to compact asphalt and soil in order to create stable roadbeds. The powerful and efficient nature of engine tamping rammers makes them ideal for preparing large areas for paving, such as highways, bridges, and airport runways.

Additionally, engine tamping rammers can be used to repair damaged road surfaces, making them an essential tool for road maintenance.

In landscaping and garden design

Engine tamping rammers are used to compact soil and prepare areas for planting. They are also used to create garden paths, retaining walls, and other hardscaping features.

The precision and control provided by engine tamping rammers makes them ideal for working in confined areas and creating uniform, attractive garden designs.

Advantages of an Engine Tamping Rammer

Engine tamping rammers offer several advantages with respect to efficiency, durability, and user-friendliness. These are further discussed below.

Efficiency

Engine tamping rammers are faster and more efficient than manual compaction methods. They can compact a larger area in less time and provide more consistent and uniform compaction across the entire project area.

This can help to reduce the overall time and cost of a construction project, making it more efficient and cost-effective.

Durability

Engine tamping rammers are designed to withstand tough construction conditions and frequent use. They are built with high-quality materials and are engineered to last. This means that engine tamping rammers are a long-lasting investment that can provide reliable performance for years to come.

User-friendliness

Engine tamping rammers are easy to operate and maintain. They can be operated by one person, reducing the need for manual labor and reducing the risk of injury.

Additionally, engine tamping rammers are equipped with ergonomic handles and adjustable guides, making them comfortable and easy to use. The low-maintenance design of engine tamping rammers makes them a hassle-free investment that can be used with minimal downtime.

Maintenance and Safety Tips

Regular maintenance and safety precautions are essential for ensuring the longevity and safe operation of engine tamping rammers. Here are some tips to help keep your tamping rammer in good condition and to ensure safe operation:

Maintenance Tips

- Regular oil changes: Regularly change the oil in your engine to ensure smooth and efficient operation.

- Clean the air filter: A dirty air filter can reduce engine performance, so make sure to clean it regularly.

- Check and tighten bolts and nuts: Regularly inspect the bolts and nuts holding the engine, handle, and tamper plate to ensure they are tight and secure.

- Lubricate moving parts: Regularly lubricate moving parts, to ensure smooth operation and reduce wear.

Safety Precautions

- Wear protective equipment: Always wear protective gear, such as safety glasses and ear protection, when operating a tamping rammer.

- Keep a safe distance: Always keep a safe distance from the tamper plate when the engine is running to avoid injury.

- Avoid overloading: Overloading the tamping rammer can cause damage and increase the risk of injury, so always use the tool within its recommended weight capacity.

- Never tamper with electrical systems: Never attempt to tamper with electrical systems or wiring, as this can be dangerous and cause damage to the tamping rammer.

- Train operators: Ensure that all operators are properly trained and familiar with the safe operation of the tamping rammer.

Conclusion

An engine tamping rammer is a powerful and versatile construction equipment. It offers several advantages over manual compaction methods, including increased efficiency, durability, and user-friendliness.

In addition, engine tamping rammers are designed to be low-maintenance and easy to operate, making them a smart investment for contractors, builders, and landscapers.

Looking to the future, there is a growing demand for engine tamping rammers that are more efficient, user-friendly, and environmentally sustainable. As technology continues to advance, we can expect to see new and innovative developments in tamping rammers that offer greater performance and reliability, making them even more valuable tools for the construction and landscaping industries.

Leave A Comment