Tamper vs Compactor:Which is The Better Tool For Your Project

Compaction is an essential process in construction. It helps attain the needed construction material density for load bearing structures. These include structure foundations and road subbases. Several equipment can be used for compaction. The choice of equipment depends on the nature of work to be done and expected outcome.

Some of the most common compaction equipment include rollers, rammers, and plate compactors. This article is focused tamping rammers and plate compactors and their essence in the construction industry.

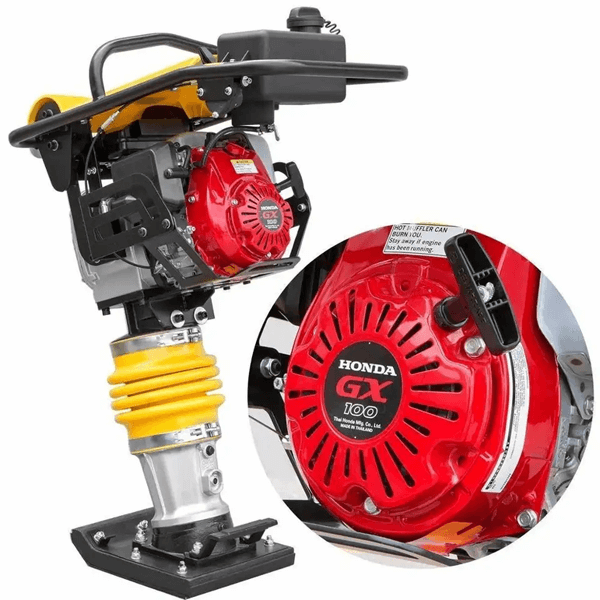

A tamping rammer is a piece of equipment with power generation mechanism; engine or electric powered, with a foot made of strong material such as steel. Compacting force generated by the engine or electricity is transmitted to the ground through an up and down movement of the foot.

Plate compactors have the same power generation mechanism as tamping rammers. However, the compacting force is transmitted to the material through a square or rectangular steel plate. The rammer and compactor are discussed in detail below.

Contents

Tamper

Tampers (tamping rammer) are applicable in a variety of projects. They come in different sizes and features. The choice of a tamper to use depends on aspects such as project size, expected output, working conditions, and contractors’ personal preferences.

Tamping rammers are classified into engine-powered and electric powered. Technological advancements have been done on tamping rammers to maximize output while reducing operational costs. For instance, some engine powered tampers have air cleaners to elongate the engine working life and enhance the performance.

Here are some of the main advantages of using tampers in compaction;

Portability

Tamping rammers are generally smaller making them ideal compaction equipment for remote jobs. Some tamper brands, such as Mikasa have side mounted handles for easy loading and unloading.

Ease of use

In modern tampers, ergonomic aspects are highly considered in the designs. The tampers are made to maximize comfort and minimize technical knowledge needed to operate them. Mikasa, a renowned manufacturer of tamping rammers, uses high-tech dampers to reduce the vibration reaching the operator. In some models, Mikasa installed tachometers that help operators monitor engine RPM and operating hours.

Versatility

To cover the construction industry, tampers are manufactured to adapt in a wide range of project sizes, locations, and size conditions. Electric tampers are ideal for areas that require minimal noise and emissions, such as hospitals. Since such tampers require a power source, one can use diesel powered tampers for remote projects. Some tampers have levers which can be used to adjust the engine power to deliver the required compacting force. Such rammers can be used in multiple projects or used in one project that requires different levels of compaction.

Compactor

Compactors (plate compactor) are applicable to a variety of compaction activities. However, their application is limited when it comes to tight spaces. Compactors come in different sizes, and deliver a more even and faster compaction than rammers.

Plate compactors are also classified according to their power source. Engine-powered compactors are convenient for larger projects that require higher degree of compaction. Movement of compactors is by the vibration of the steel plates in contact with the ground. The vibration can be set using a lever to attain forward and reverse motions while compacting construction material.

Here are some advantages of using a plate compactor in construction;

Power and efficiency

Compactors deliver higher power compared to tamping rammers. The combined weight of the engine and compacting plate deliver a higher compacting force. Unlike tampers, compactors move by their own vibration; the consistent contact with the ground ensures an even compaction is attained.

Heavy-duty construction

Some construction projects involve compacting hardcore over large areas. Such projects require a higher compacting force that tampers can deliver. Engine powered compactors deliver high compacting force ensuring the desired results are attained. The uniform compaction delivered by compactors allows the compaction process to be done in layers whenever necessary. For instance, hardcore compaction in buildings is done in layers to attain the needed base strength for heavy construction.

Large capacity

The steel plate on compactors is relatively large compared to tampers. This implies that a larger area can be covered over a shorter time when using compactors. The high frequency vibration allows smooth movement of the compactor over material. Additionally, some compactors are made with dampers and other ergonomic features that minimize operator’s fatigue. This allows the operator to work efficiently over longer hours.

Comparison Between Tampers and Compactors

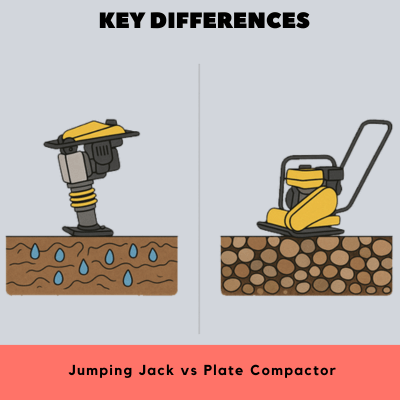

Tamping rammers and plate compactors are two popular equipment used for compacting soil and asphalt. Both have their own unique strengths and weaknesses, and the best choice between the two depends on the specific compaction needs of a project.

Applications

Tamping rammers are designed for compacting construction material in confined spaces and tight areas, such as sidewalks, walkways, and driveways. Plate compactors, on the other hand, are designed for larger compaction projects and can be used on a variety of surfaces, including gravel, asphalt, and soil. Plate compactors are ideal for compacting soil and asphalt in open areas such as parking lots, roads, and bridges.

Cost

Plate compactors are generally more expensive than tamping rammers, mainly because of their larger size and greater compaction capabilities. However, the cost of either type of equipment depends on the specific model and its features.

Performance

Plate compactors are more powerful and can cover a larger area in a shorter time. They are also equipped with larger plates, making them more effective for compaction in open areas. Tamping rammers, on the other hand, are designed for precision compaction in tight spaces and are better suited for applications that require a high-frequency impact force.

Conclusion

Tamping rammers and plate compactors are two popular equipment used for compaction. Tamping rammers are designed for compacting soil and asphalt in confined spaces and tight areas, while plate compactors are designed for larger compaction projects in open areas. Tamping rammers offer the right balance between portability, ease of use, and versatility, making them a popular choice for a variety of compacting applications. Plate compactors, on the other hand, are more powerful and can cover a larger area in a shorter amount of time.

When choosing the right tool, it is important to consider the specific compaction needs of the project. If a project requires compacting over a large open area, a plate compactor is the best choice. If the project requires precision compaction in a confined space, a tamping rammer is the ideal choice.

It is important to carefully consider the specific needs of a project and choose the right tool for the job. Both tamping rammers and plate compactors can save time and effort while providing efficient and reliable compaction results.

Leave A Comment