How to Use Concrete Cutter Like a Pro [Step By Step]

Concrete cutters are used for grooving in the concrete surface, masonry, asphalt surfaces. Such machines vary in size and power, providing versatility. Such as the work they can handle, and these machines can be used in small DIY jobs.

They are equally useful for large-scale construction and many more applications. It is essential to know how a concrete cutter is used. It will make you work quicker, safer and in a cleaner environment.

It will cut smoothly and in a professional style. Moreover, it will decrease the possibility of breaking something. You can learn to operate the saw used to cut slabs or be part of a demolition crew in this guide.

Contents

What Is a Concrete Cutter

A concrete cutter is a machine that is constructed to cut into solid materials. It is also a very popular tool to cut concrete, asphalt and the like with the help of a fast-rotating blade. You will find that it is common in peeling off road jobs, laying pipes, and demolition.

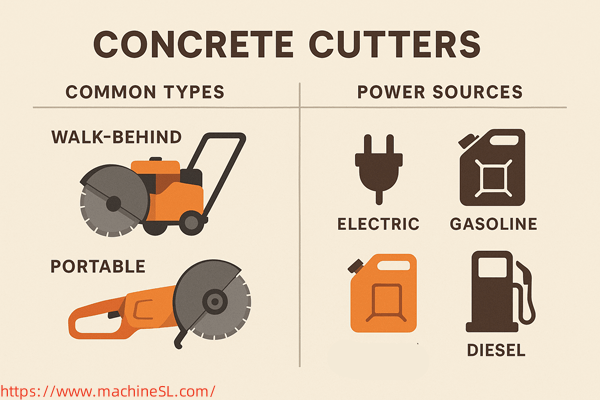

Common types:

- Walk-behind Concrete cutter: These cutters possess a lot of control and stability. This type of saw is made to cut long and straight cuts. For example, expansion joints or concrete trenching.

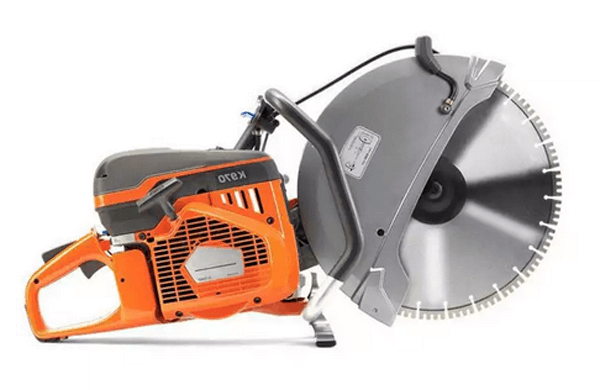

- Portable concrete cutters: These can be smaller and portable. Thus, they are ideal in tight working areas, high places or horizontal areas. They are comfortable plunging and excellent at performing precision tasks.

Power sources:

- Electric: These are Silent, emission-free, non-odorous, non-polluting. Therefore, it would be preferable when confined to a noiseless workplace.

- Gasoline: Portable and high-powered, the gasoline products have wide applications. Especially, they are effective in outdoor construction sites that lack a power supply. But they produce fumes and require ventilation.

- Diesel: Designed to perform the nicest (most strenuous) jobs. They are common on large infrastructure where power and durability are priorities, in dusty or rough settings.

When and Why You Need to Cut Concrete

Cutting concrete is often necessary during both construction and renovations. It helps you make precise changes, create access for utilities, or control how the material behaves as it cures.

Common reasons to cut concrete

- Expansion and control joints: These can be used to prevent intermittent cracks. It allows the concrete to release the tension on temperature changes or contraction.

- Repairs or demolition: Repairs or demolition can be easier. When damaged parts can be removed using cutting, it becomes more convenient.

- Utility fittings: You can provide utility fittings by cutting. Cuts give you the opportunity of laying the plumbing, electrical lines or even the drainage system where needed.

When to cut

- Early entry cutting (1–4 hours after pouring): This is done with lightweight saws and special blades to create clean joints before the concrete sets too hard.

- Standard cutting (6–12 hours after pouring): Done once the concrete hardens a bit more. Deeper cuts are possible, but there’s more risk of chipping if mistimed.

Choosing the Right Concrete Cutter

The correct choice of the tool and blade will help to make your work much easier and safer.

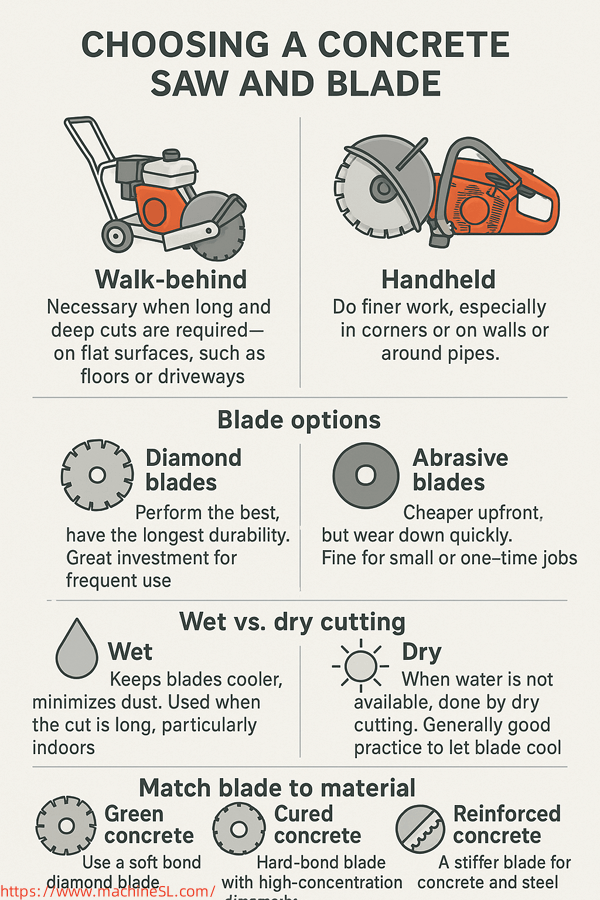

Saw types

- Walk-behind: A walk-behind saw is necessary when long and deep cuts are required. It becomes essential if cuts are required on a flat surface, such as floors, driveways or foundations.

- Handheld: Do steer work with a handheld cutter, especially in corners or on walls or around pipes.s.

Blade options

- Diamond blades: These blades perform the best, have the longest durability. They can cut cured concrete, reinforced concrete, or green concrete. A great investment for frequent use.

- Abrasive blades: Cheaper upfront, but wear down quickly. Fine for small or one-time jobs—just not great for tough or reinforced surfaces.

Wet vs. dry cutting

- Wet – Wet cutting keeps blades cooler, minimising the dust. It is used when the cut is long, particularly indoors.

- Dry – when water is not available, it is done by dry cutting. It is always a good idea to take a few moments every once in a while to let the blade cool. It is generally good practice to keep the area well ventilated.

Match your blade to the material

- Green concrete: As an aid, use the soft bond diamond saw blade. It cuts through newly poured, uncured concrete easily.

- Cured concrete: The concrete has to be cured with high-concentration diamonds at a high concentration. It is necessary to yield clean results using a hard-bond blade.

- Reinforced concrete: This will need a stiffer blade that can cut concrete and steel.

When choosing the right equipment to go with, also consider how deep the cut should be. It is also important that how fine the task is, and how big the space should allow for the correct choice.

Preparation Before Cutting

Before you even begin the operation, a few simple steps will prevent injuries. It will make the operation easier.

Safety gear:

- Trained personnel should always wear safety gear. These must be protective goggles or a face shield, earplugs, a glamorous, and a dust mask or respirator. Concrete cutting is noisy and dusty.

Check your surroundings:

- Also look for hazards that could be concealed rebar, live wire. Scan a device, or you can ask your local authorities to know, in case you are not sure.

Mark your lines:

- Long and straight cuts should be done with the help of the chalk lines. Waterproof markers are to be utilized on wet areas. Two cuts are better than one.

Clean the surface:

- Clear away the trash that could result in impacting the blade. A clean flat surface will give you better results.

Set depth and guard:

- Set the cutting depth by using the blade setting by touching the blade setting to the desired depth.

- Dust and debris are also confined because the lower the blade, the better. Ensure that the blade guard is a bit above what you want to cut, though.

If using wet cutting:

- Connect a water source. Install a hose that has a control valve. Ensure that there is even water flow over the blade to allow it to cool and manage dust.

How to Use a Concrete Cutter Step-by-Step Guide

You can use a concrete cutter as below:

Step 1: Start the Machine

- With gas or diesel cutters, refill the fuel, examine oil levels, clean the filter and examine the spark plug.

- In case of electric cutters, ensure that the source of power is safe, dry and well grounded.

- Do a proper warm-up as per the user manual.

Step 2: Position and Start Cutting

- Align the blade with your marked line. Use guides if your saw has them.

- Lower the blade gently. Never drop it onto the surface—it can chip the concrete or damage the blade.

Step 3: Maintain Control

- Keep a steady pace. Let the blade do the work without forcing it.

- In dry cutting, the blade should cool after stops. Be aware of blazing signs of smoke or burning smells.

- Keep the depth consistent by using a gauge or ruler.

Step 4: Finish the Cut

- Grind to a halt at the finish. When done, lift the blade slowly.

- Wait until the blade stops spinning and then turn off the saw before moving the machine.

- Look at your cut. It ought to be neat, straight, and deep enough.

Best Practices for Quality and Safety

Safety is priority. So, practicing the following will lead to good quality and better safety at work.

- When the opportunity presents itself, cut wet–it is simpler and easier on the blade.

- Segmented diamond blades can be used to do reinforced or heavy-duty work.

- In case of rough edges, it is better to avoid cutting down until the middle of the working process and start it again.

- You should regularly check your saw and see that there are no loose belts or worn parts.

- Pay attention, particularly to such hindrances as wiring, walls, or traffic. In such cases, a spotter will help a lot.

Common Mistakes to Avoid

One must avoid the following mistakes while using a concrete cutter.

- Cutting too early: If cutting the concrete too early, edges are likely to split or crack.

- Cutting too far: You can face uncontrolled splitting. Since the concrete expands and shrinks.

- Wrong blade: Using the wrong blade type is a waste of time, tool damage and ruined cuts.

- Not wearing PPE: Wearing gear always causes hazards. Dust, noise, and flying particles can cause injury for real.

- Too much force: Overwhelming the blades will not do better—it will only worsen the blade.

- Erratic motion: Shots make ugly lines and punch in weak areas of concrete.

Maintenance Tips for Concrete Cutters

A little care goes a long way in keeping your concrete cutter in top shape.

- Instead, a bit of attention goes a long way in ensuring that your concrete cutter is in its best shape possible.

- After use, cleaning: Wash out dust residues or mud with a brush or pressurised air. Clean blades with clean water and wash them off.

- Eye Inspection of the blade: Checks, dents or a deformed shape. And damaged blades go to be replaced at once

- Oil models: substitute the oil and oil check. Change or clean wash air filters.

- Keep it away: Place your cutter in a dry and covered place. Avoid the severe weather.

FAQs

Can I use the same cutter for asphalt or stone?

Certainly, yes, as long as you use the proper blade. Asphalt needs a softer blade, while stone may require a turbo or segmented blade.

What blade should I use for reinforced concrete?

You should use a laser-welded diamond blade to cut concrete and rebar.

How deep can I cut with a handheld saw?

The majority of the handheld models are 5 inches deep. A bigger blade on a walk-behind saw is more appropriate in the case of deeper cuts.

Do I always need water to cut concrete?

Not always, but wet cutting is recommended whenever possible. It reduces dust and keeps blades cool. Use dry cutting only for short jobs or where water isn’t an option.

Conclusion

A concrete cutter initially is a very daunting piece of equipment to work with. It may be quite easy and quick with proper preparation, equipment, and methodologies. You can use the equipment for both – an easy groove or cutting a thick slab.

So, it can make the whole job a little cleaner, quicker and a lot safer. Pause before a cut, select the right blade, safety measures.

Timing and conditions are critical to avoid mistakes and improve efficiency. Worst of all–let the blade itself do the work. In no time and with practice and care, you will surely be cutting concrete like a pro.

Leave A Comment