What Is Plate Compactor? How Does It Work & How to Use

A successful construction project depends on a strong foundation as its primary element. Solid construction requires stable ground underneath, surfaces, sidewalks, and roads. Loose soil leads to the formation of cracks and dips and causes structural failures.

This is where a plate compactor becomes essential. This guide breaks down its parts, functions, and usage. This article contains pro tips to get the job done right.

Contents

What Is a Plate Compactor

Definition and Purpose

The plate compactor functions as a vibrating or Wacker plate to compress the soil. The machine uses a heavy vibrating plate to apply downward pressure on the ground.

The main goal is to densify materials by raising their content. It also decreases the risks of changes in material position or loss from elements. The failure rate of paving or foundation work becomes low after compaction.

Why Compaction Matters in Construction

Inadequate compaction causes structural failures. Roads may develop potholes. Pavers may sink or wobble. Soil with poor compaction becomes vulnerable to frost heave and water penetration.

Soil compaction activities boost soil-bearing capacity by 30% to 50%. Compaction-enhanced soils can bear higher structures and traffic loads.

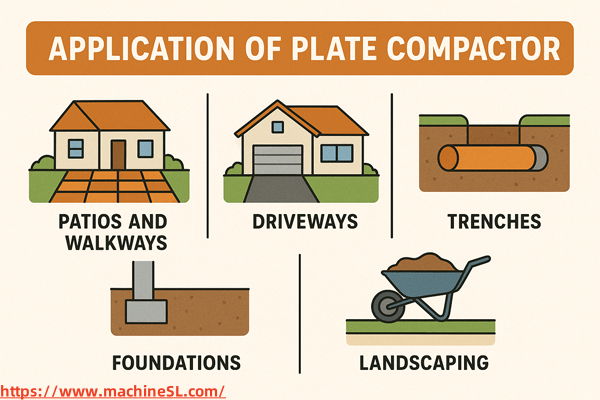

Common Applications

Soil compaction of soil is important in many structures, whether load-bearing or non-load-bearing. Yet, the following are common applications of compaction.

- Patios and walkways –Compaction of patios and walkways prevents uneven paver surfaces.

- Driveways – For driveways, compaction provides a solid base for gravel or asphalt.

- Trenches – Compaction ensures that pipes or cables remain undisturbed in trenches.

- Foundations – It strengthens the ground before pouring concrete into the foundations.

- Landscaping – For landscapes, it levels out topsoil, sand, or other base layers.

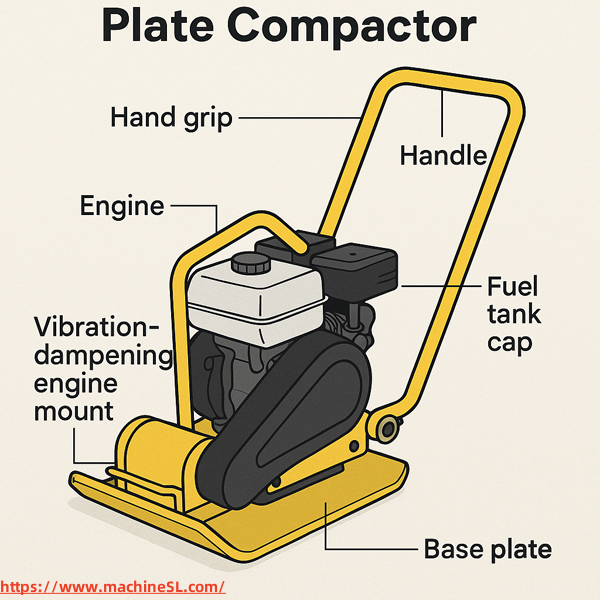

Key Components of a Plate Compactor

Keeping the importance of compaction in mind, let’s explore the tool for compaction. The most common equipment for compaction is a plate compactor. Now, here you can have a detailed glance at the plate compactor.

Engine

Engines of plate compactors range from 3 to 9 horsepower. Commercial models and standard gasoline engines use diesel. However, the majority of portable generators operate with 4-stroke gasoline motors. Most people trust the reliability of the Honda GX160 or Kohler models.

The engine powers the vibrator shaft and base plate. A larger engine means deeper and more powerful compaction.

Base Plate

Base plates are made of solid steel or cast iron. They usually range from 16 to 24 inches wide. Heavier plates produce stronger compaction but may be harder to manoeuvre.

Some plates are tapered or curved at the front edge. It helps with smooth movement across surfaces without digging in.

Eccentric Vibrator Mechanism

The eccentric vibrator mechanism handles producing vibration. It is located inside the base, the spinning shaft holds an off-balance weight. As it rotates, it generates vibration that shakes the entire machine.

This vibration is what forces particles of soil or gravel to lock together tightly.

Handles and Controls

Long handles reduce operator fatigue and improve control. Many compactors feature vibration-dampening grips to reduce hand-arm vibration syndrome (HAVS).

Controls typically include a throttle, an on/off switch, and sometimes a water spray valve. The water spray valve is for asphalt jobs.

Optional Water Tank

The optional water tank is useful when compacting hot-mix asphalt. The applied water layer prevents the plate from acquiring trapped material. It extends the operational life of machines while enhancing their output finish quality.

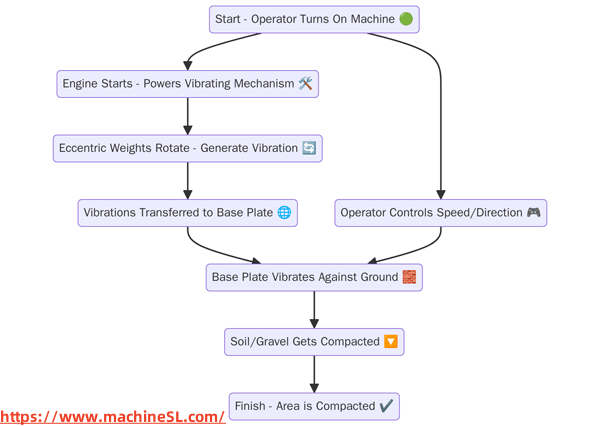

How Does a Plate Compactor Work

One must grasp the basics of soil compaction to understand the working mechanism. Here are some brief explanations for the working of plate compactors.

Soil Compaction Basics

Soil contains solid components, water elements and air space. The major goal of compaction is to remove air between particles. It reduces the space between particles and increases density and strength.

During compaction, moisture plays a key role. The ideal compaction level is achieved with the optimum moisture content in the soil. It lies between 10%-20% for granular soils.

Vibration from Eccentric Weights

The off-centre rotating weights produce vertical vibration. This motion loosens the soil momentarily. Then the machine’s weight presses it downward.

Compactors vibrate at 2,000–6,000 vibrations per minute (VPM). Higher VPM is better for granular soils.

Impact and Downward Force

Each vibration is like a mini-impact. The force drives particles downward and eliminates voids. Machines exert anywhere from 1,000 to 4,000 pounds of centrifugal force.

Continuous Motion

As the vibration occurs, the machine “walks” forward. Operators follow behind, guiding the compactor in rows. Reversible models can move back and forth, reducing the need for turning in tight areas.

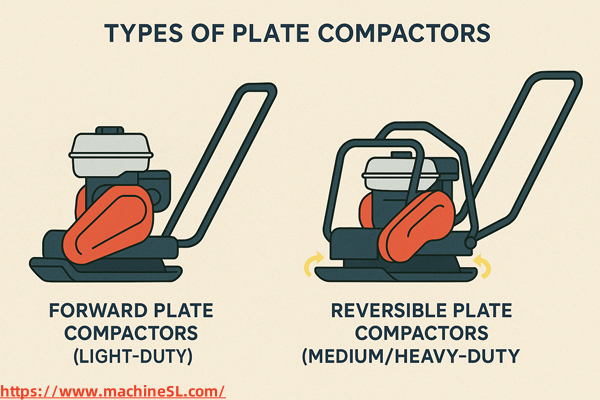

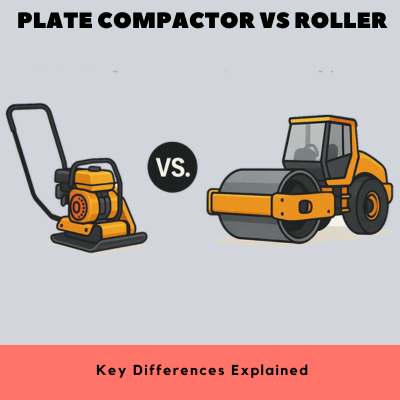

Types of Plate Compactors

According to the purpose and specifications, there are two types of plate compactors.

Forward Plate Compactors

Light and ideal for smaller jobs. Weigh between 100–200 lbs. Great for walkways, patios, and home landscaping.

Reversible Plate Compactors

Mid to heavy-duty machines weighing 300–1,000+ lbs. Used in commercial applications and roadwork. The ability to move in both directions increases efficiency.

Comparison Table

Here is a comprehensive comparison between forward and reversible plate compactor as below:

| Type | Typical Weight | Ideal Use | Force Output | Direction |

| Forward | 100–200 lbs

| Patios, small foundations | ~3,000 lbs | Forward only |

| Reversible

| 300–1,000 lbs | Roads, trenches, driveways | ~4,500–9,000 lbs | Forward/Reverse |

How to Use a Plate Compactor

Let us understand the workings of a plate compactor in detail. The process of compaction should encompass the following:

Pre-Use Preparations

Before using or even switching on the plate compactor, there are some preparations. These are musts as they provide safety, smooth operations and risk risk-free environment. The following are the pre-use preparations for operating plate compactors.

- Check Fuel, Oil, and Air Filter

Checking the fuel, oil and air filter can reduce the chances of machine failure. Low oil or dirty filters can damage the engine. Always inspect levels and cleanliness.

- Wear Safety Gear (PPE)

Plate compactors produce high noise and dust during operations. One must ensure the use of PPE. Gloves protect from vibration. Goggles prevent dust irritation. Ear protection guards against loud noise levels, often exceeding 90 dBs.

- Inspect the Site

Before compaction, it is advisable to thoroughly check the site. Remove large rocks, tree roots, or debris. Wet areas may need draining before compaction.

Operating Steps

Adequate measures before operating plate compactors make the operations smooth. For proper compaction, follow the steps below:

- Start the Engine Safely

Engage the choke, turn on the switch, and pull the cord firmly. Let the engine warm up before full throttle.

- Hold and Guide the Machine

Use both hands. Keep feet at a safe distance. Steer the compactor smoothly and avoid jerky motions.

- Compact in Overlapping Passes

Overlap each pass by 25–30%. Use a chalk line or string guide for straight alignment.

- Maintain Consistent Speed

Too fast? You’ll miss spots. Too slow? You risk over-compaction. Aim for a walking pace.

- Shut Down and Clean

Turn off the fuel valve. Let the machine cool. Clean off soil and debris with a wire brush or scraper.

Pro Tips for Best Results

As this article is a detailed and extensive guide, here are some professional tips. Adopting these tips can achieve the best compaction result. It also helps to prevent any operational risk. For example,

- Compact soil in layers 2–4 inches thick. It will result in the optimal compaction of soil.

- Slightly moist soil compacts better than dry or saturated ground. It prevents excessive dust and the easy compaction of soil particles.

- Don’t compact frozen ground—it can lead to frost heave.

- For paved surfaces, use the water tank feature to prevent sticking.

Common Mistakes to Avoid

Some common mistakes can occur during the operation of plate compactors. These mistakes can lead to a tough situation at the site during soil compaction. Such as:

- Skipping the moisture test. Dry soil will resist compaction.

- Using a forward-only compactor on a large site.

- Leaving the machine idle with fuel on, can cause serious injuries in case of failure.

- Compacting more than 6 inches in one pass. This will result in improper compaction.

Maintenance and Safety

As you know, machinery needs proper care, and it will serve you as you want. A plate compactor is a helpful piece of equipment. It needs to be maintained properly and checked in a routine. So here is a daily maintenance checklist for plate compactors.

- Fuel: Check levels and leaks

- Oil: Top off if low

- Bolts: Tighten all fasteners

- Belt: Inspect for cracks or looseness

Cleaning and Post-Use Care

Use compressed air to blow out dust. Wipe down controls and handles. Store dry to avoid rust.

Proper Transport and Storage

Use a ramp for loading. Secure with tie-down straps. Store upright in a locked shed or trailer.

Operating Safely Around Unstable Ground

Stay away from slopes greater than 20°. Don’t compact near open trenches—they can cave in under vibration.

Taking Breaks to Avoid Vibration Fatigue

Use padded gloves. Take breaks every 30–40 minutes. Switch tasks to reduce exposure.

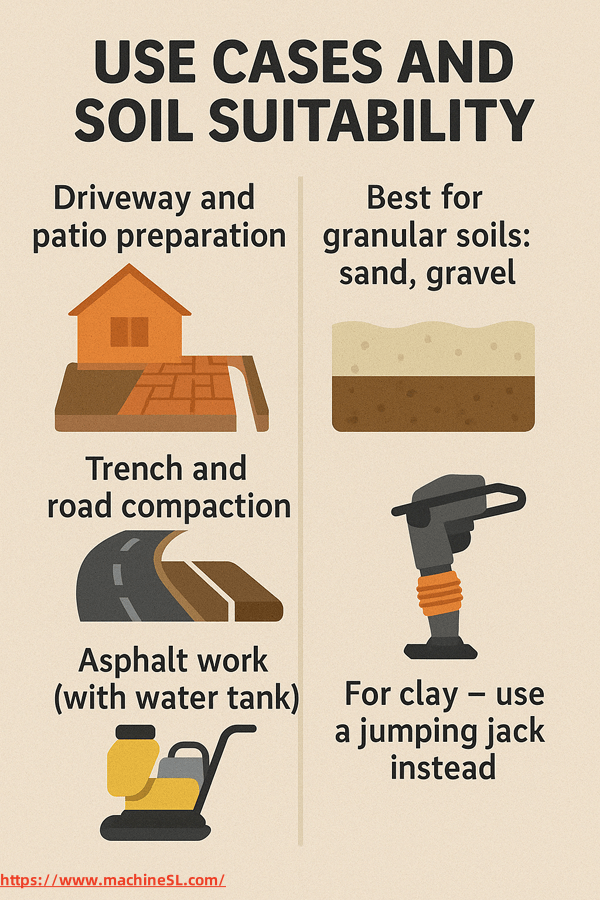

Use Cases and Soil Suitability

The construction and landscaping needs plate compactors for soil and gravel compaction tasks. The following presents the primary deployment instances of plate compactors:

Driveway and Patio Preparation

Before laying bricks or pavers, compact a crushed gravel or sand base. Prevents future movement and weed growth.

Trench and Road Compaction

After laying pipes, compact the backfill soil to prevent sagging. Reversible compactors excel here.

Asphalt Work (With Water Tank)

For hot mix asphalt, use a plate compactor with water to prevent sticking and tearing.

Best for Granular Soils: Sand, Gravel

Granular soils compact well because they lack cohesion. Plate compactors work best in these conditions.

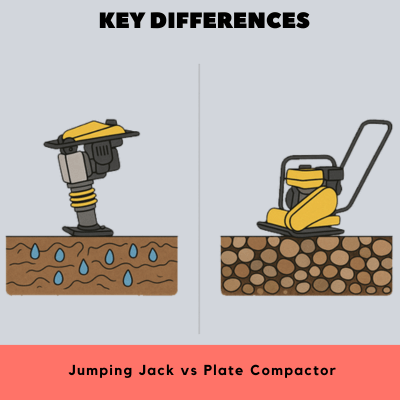

Avoid on Clay – Use a Jumping Jack Instead

Clay is cohesive and resists vibration. Instead, use a rammer (jumping jack) that delivers vertical impact.

Frequently Asked Questions

Can You Compact Wet Soil?

Yes, you can compact wet soil but only if it’s slightly damp. Too much water makes the soil mushy and hard to compact.

How Deep Can You Compact?

With plate compactor each pass compacts about 2–4 inches. For deeper compaction, apply multiple layers.

How Many Passes Are Ideal?

Number of ideal passes varies but generally, 3–6 passes are enough. Use a soil test (Proctor test) for accuracy.

Wacker Plate vs. Plate Compactor – What’s the Difference?

There is no difference between Wacker plate and plate compactor. “Wacker” is a brand. It’s now a general term used like “Band-Aid” for adhesive bandages.

Should You Rent or Buy for Small Projects?

Renting is ideal for occasional use. Costs range from $40–$80/day. If you need one regularly, buy a plate compactor unit for $400–$1,200.

Leave A Comment