Plate Compactor VS Roller? Key Differences Explained

Do you need a dependable base for your construction or landscaping effort? It is essential to get the soil right. The top two tools used in the job are the plate and roller compactors.

The machines are designed to cope with soil, gravel, or asphalt compaction. Their differences are visible in size, the tasks they perform. Similarly, they have different cases for which they are best suited.

Choosing the appropriate machine is important. A bad choice might result in weak structure, more effort, and more expenses.

This article is useful no matter if you’re a contractor or want to do work yourself. It will help you pick the correct one for your project.

This information examines the differences between plate compactors and rollers. We are going to review the mechanics and recommend the right place for both machines.

Contents

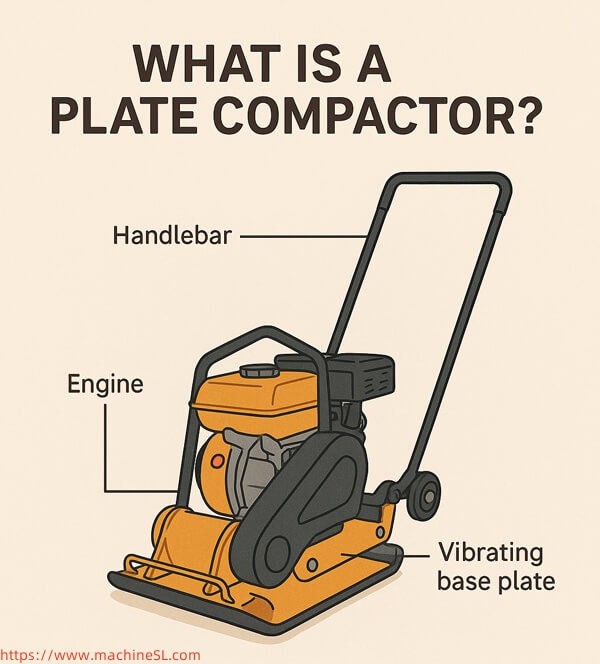

What Is a Plate Compactor

A plate compactor is a machine used to compact soil, gravel, or asphalt as you walk behind it. The equipment has a large, thick steel plate that shakes very quickly.

Vibrating the machine forces the particles in the powder to get closer together. The weight of the machine allows it to do so.

The result? A smoother and sturdier floor. You’ll find these machines at construction and landscaping sites. Compactors help in repairing foundations, sidewalks and other small flat surfaces.

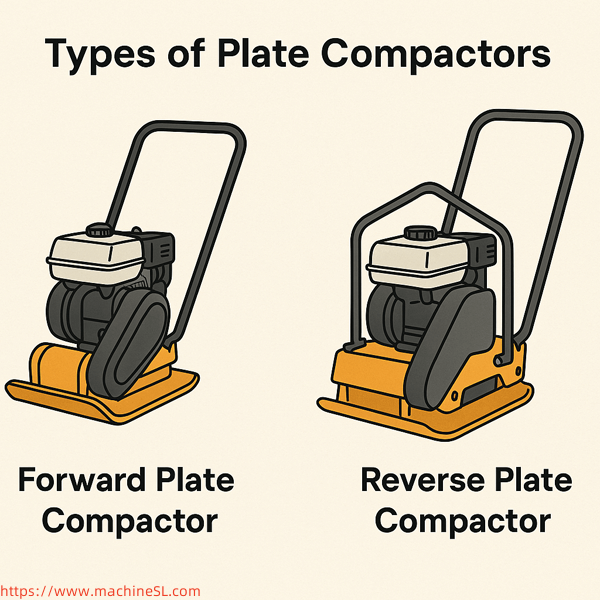

Types of Plate Compactors

Two types of plate compactors are commonly used. These are:

- Forward Plate Compactor

A forward plate compactor is one of the best tools for most everyday projects. It is both simple to use and effective.

It moves only forward with vibration produced by an engine-driven weight. Shaking the soil or rocks eliminates air pockets, promoting strong compaction.

- Reverse Plate Compactor

A plate compactor that is able to be reversed. Backwards and forward movement is possible with these models. They make it easier to handle your finances.

They are used to work on smaller surfaces with a lot of layers. Reverse compactors are often bulkier and pricier, but they are also easy to use and efficient.

Common Use Cases

The plate compactor is not ideal for cohesive soils, such as clay. Yet they have a wide range of applications. These application areas cover:

- Preparing sidewalks and small driveways

- Compacting trenches or tight spaces

- Landscaping beds and garden paths

- Patchwork on asphalt

- Granular soil compaction, like sand or gravel

What Is a Roller Compactor

Roller compactors are machines that compact soil, asphalt, or other materials. It uses cylindrical drums. These drums can be smooth, padded, or pneumatic.

Some are ride-on machines. Others are walk-behind models. Many uses vibration in addition to weight to improve compaction depth and density.

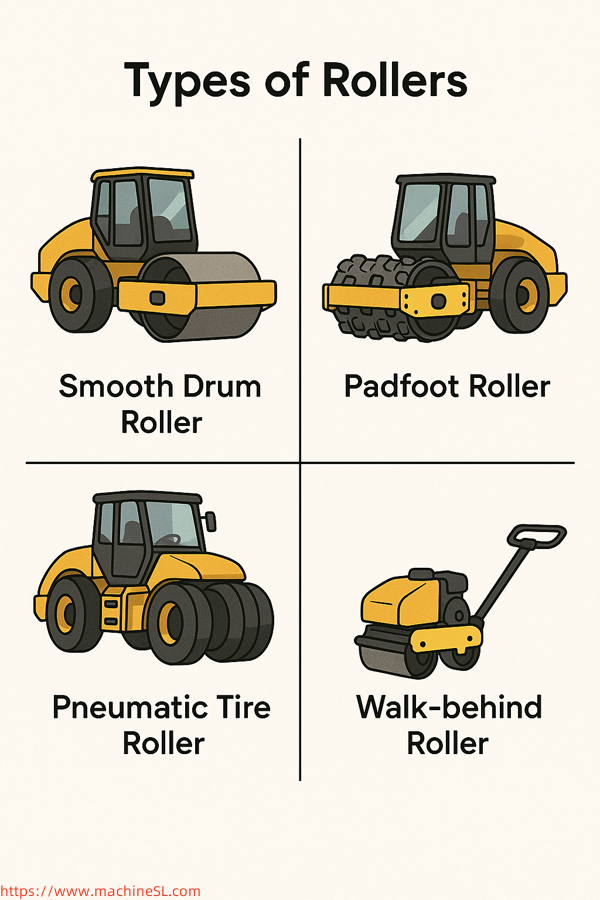

Types of Rollers

There are generally four types of roller compactors used in the construction industry. Such as:

- Smooth Drum Roller

If you need to compact sand, gravel or crushed rock, smoother drum rollers will work best. You’ll often see them during road building, like on highways and big lots for parking.

These machines use a large and smooth steel drum to evenly compress materials. This roller, with either force from vibration or no movement, compacts the soil.

They are great for the foundation and final asphalt paving process due to their smooth finish.

- Padfoot Roller

The name Padfoot is also known as Sheepsfoot Roller. The padfoot roller or sheepsfoot roller is made to compact clay and silt soils.

The lugs or pads on the drum help to work and mix the soil as the roller passes. This action remixes and loosens the soil layers. it is most effective in projects that require very strong bonding among the soil grains.

The padfoot roller is not ideal for material that is abrasive or grainy. It is ideal where adding water and precision in compaction are major priorities.

- Pneumatic Tire Roller

Pneumatic tire rollers replace the steel drums used in old rollers with rubber tires. They rub and massage the surface, always pressing firmly. This helps make the material more even and dense.

Class A compaction rollers are used at the finishing of asphalt paving. They seal better and deliver better results because the tire can adapt to small surface changes.. Their value lies most in highway paving, airport runways and similar high-traffic areas.

- Walk-behind Roller

For compact jobs where workspace is limited, you can use walk-behind rollers. They work better than plate compactors. Hence, they can be used on driveways, sidewalks, for repairs and on landscaping projects.

Most walk-behind rollers are controlled by hand and often come with one or two drums. They are portable and easy to operate. These machines are perfect for people doing construction work in tight spaces or at homes.

Common Use Cases

Roller compactors are powerful, but they require more space and expertise. These are useful for:

- Highway and road construction

- Large parking lots

- Airport runways

- Preparing foundations for large structures

- Effective on cohesive soils like clay or silt

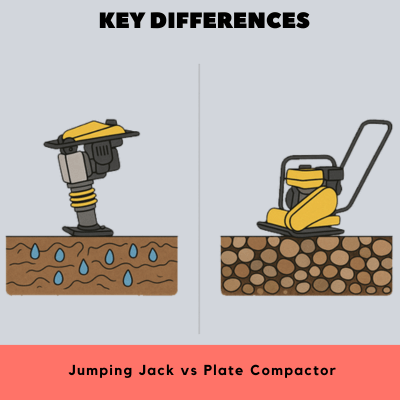

Key Differences Between Plate Compactors and Rollers

Each machine has its strengths. The best choice depends on project scale and soil conditions. The comprehensive key differences between plate compactors and rollers are as below:

| Feature | Plate Compactor | Roller Compactor |

| Size | Compact, walk-behind | Large, ride-on or walk-behind |

| Soil Types | Best for granular soils | Granular & cohesive soils |

| Area Coverage | Small areas, confined spaces | Large areas, open spaces |

| Power/Force | Vibration only | Weight + vibration |

| Manoeuvrability | Excellent in tight spots | Limited in small or uneven spaces |

| Use Stage | Pre-construction compaction | Final compaction after layering |

| Cost | Lower purchase/rental cost | Higher upfront & maintenance costs |

Which Is Right for Your Project

Choosing the right equipment depends on different factors. By considering these points, you can make better decisions. The following are some important factors.

Project Size

First of all, one must consider the size of the project. Plate compactors are best for areas under 2,000 square feet. These include small patios, walkways, and trenches.

Rollers shine on larger projects. If your site is over 2,000 square feet. For example, in parking lots or on roads, a roller is more efficient.

Soil Type

For granular soils (e.g., sand, gravel), both tools can work. Plate compactors are more affordable for these cases.

But for cohesive soils like clay, rollers are essential, especially the padfoot. They provide deeper, more effective compaction.

Site Accessibility

Tight spaces? Choose a plate compactor. These machines manoeuvre easily in narrow areas, near walls, or around landscaping.

Need to cover large, open ground fast? Go with a roller. Just ensure the jobsite is accessible for a heavier, bulkier machine.

Cost & Efficiency

Plate compactors cost less. They’re easy to rent, transport, and operate.

Rollers cost more, but they also offer faster results. That’s why they are preferred for large-scale projects. However, these compactors are hard to maintain.

When to Use Both

No doubt, we have described the working scope for both roller and plate compactor above. It is possible to use the roller compactor along with the plate compactor. Such as:

- Some projects benefit from both machines.

- Start with a roller to compact deep layers. Then finish with a plate compactor to smooth and densify the top surface. This approach is common in multi-layer compaction.

- In asphalt projects, crews often use rollers first and then plate compactors. Plate compactors are there to touch up edges and joints.

- Similarly, in landscaping projects, rollers prepare the foundation. Whereas plates handle tight spots or finish work.

Safety & Operation Tips

Using machinery requires special care and consideration to maintain safe usage. Therefore, we recommend following the safety and operation tips for compactors. Both machines are safe when used properly.

Follow manuals and jobsite protocols at all times. The tips for plate and roller compactors are as below:

- Plate Compactor Safety Tips

For plate compactors, it is essential to:

- Always wear PPE: gloves, goggles, and ear protection

- Avoid using on wet clay as it carries the risk of the machine sinking

- Don’t operate on steep slopes; risk of tipping

- Use water tanks when compacting asphalt to prevent sticking

- Ensure engine maintenance is up to date to avoid a power failure

- Roller Safety Tips

While using a roller compactor, consider:

- Only trained operators should handle ride-on rollers

- Walk-behind models still need proper instruction

- Always inspect your surroundings before reversing

- Adjust vibration settings based on soil type

- Maintain brakes and hydraulic systems regularly

- Avoid turning on inclines to reduce rollover risk

Frequently Asked Questions (FAQ)

Can I Use a Plate Compactor on Clay?

Only for surface smoothing. For real compaction, especially below 6 inches, use a padfoot roller.

Clay needs kneading action and more force. Plate compactors don’t offer that depth or method.

Can I Rent Both Plate Compactors and Rollers for One Job?

Yes. This is common on multi-stage jobs. Many contractors use rollers for the base layer and plate compactors for finish work.

Renting both may cost more, but it ensures quality and meets project standards.

How Deep Can Each Machine Compact

Plate Compactor: Typically 8 to 34 inches per pass, depending on soil type, moisture, and machine weight. Multiple passes may be needed.

Roller: Can compact up to 12 inches in a single pass for heavy models. Vibratory rollers increase depth. It uses the process of oscillation and compaction at the same time.

What’s the Difference Between a Vibratory Roller and a Static Roller?

Vibratory Roller: It uses engine-powered vibration. This shakes soil particles into a tighter arrangement.

Static Roller: It uses only its weight. Less effective for deep compaction.

For cohesive soils or thick layers, vibratory rollers are a better option.

Is It Cheaper to Buy or Rent a Compactor?

Rent: Best for homeowners or one-time users. Rates vary, but plate compactors often rent for $50–$100/day.

Buy: Worth it for contractors or frequent use. A plate compactor may cost $700–$2,000. Rollers cost $10,000 and up.

If adding maintenance, fuel, transport, and insurance, renting is often more practical for small jobs.

Conclusion

Selecting between a plate compactor and a roller depends on the project requirement. Always look for the right sizer machine based on the project, the type of soil and your available funds.

If space is tight and the soil is granular, a plate compactor is your best option. When the soil is cohesive or forms large open areas, a roller, vibratory or padfoot model works best.

Reduce costs and achieve better outcomes by avoiding either excessive or insufficient compaction. When a compactor is not up to requirement, it results in poor compaction, weak structure and wasted effort.

In any uncertain situation, get advice from either rental or jobsite engineers. They have the knowledge to ensure your project has great quality. They make the project protected and your time valued.

Having the correct compactor means your foundation stands strong for years. It helps you save on both time and money.

Leave A Comment