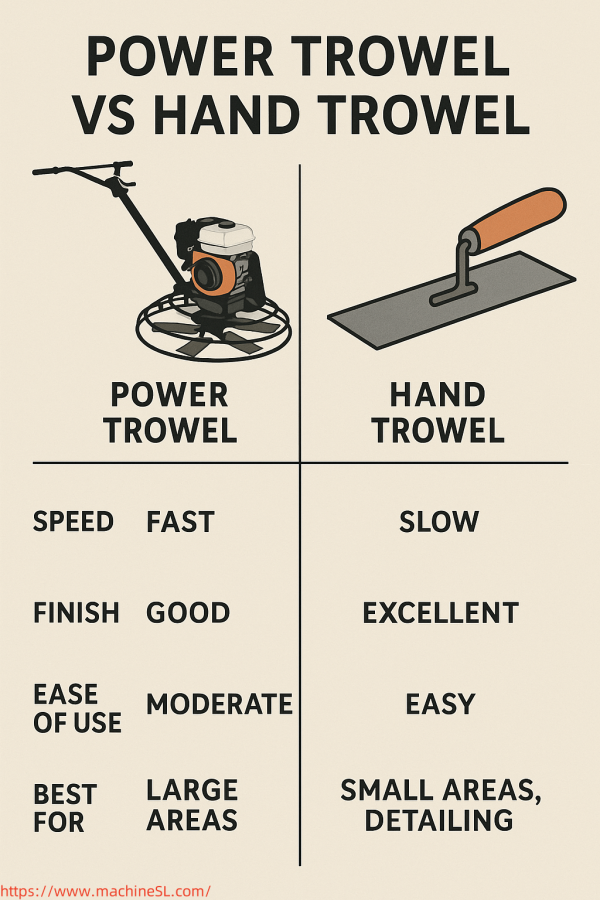

Power Trowel vs Hand Trowel: Which One to Choose

Troweling is an important component of concrete finishing. It levels off and hardens the surface, making it strong, durable, and neat.

There are two instruments that prevail in this job: power and hand trowels.

- Power trowels are high volume and made to move.

- The hand trowels result in control and precision suitable for small or detailed surfaces.

The two tools are essential, but they come in handy to satisfy different needs. The right one can save money and time, resulting in better outcomes.

This guide is a comparison between their speed, the quality of the finish, their ease of use, and the best uses. It will help you understand when to use a power trowel and when a hand trowel is better suited.

Contents

What is a Power Trowel

Here is a brief introduction to power trowel, its types, key features and advantages.

A power trowel is a machine used to finish concrete. It smooths and levels freshly poured slabs. The machine spins metal blades in a circular motion. This action compacts the surface and creates a clean, polished look. Power trowels are used on large concrete floors. They save time and improve finish quality.

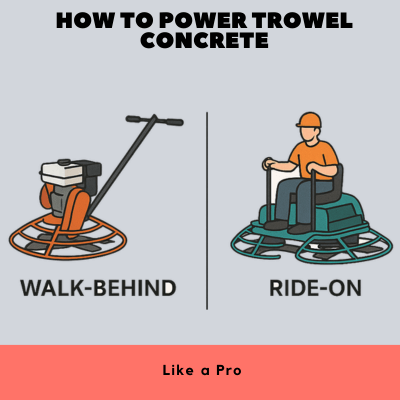

Types of Power Trowel

There are two types of power trowel.

- Walk-Behind Power Trowel

These are machines that are pushed behind. They resemble a lawn mower, and they are maneuverable. Walk-behind ones work well on small, and medium-scale projects.

- Ride-On Power Trowel

These are larger machines with a seat for the operator. The operator rides on the machine and controls it with joysticks. Ride-on trowels are made for big projects. They are more extensive and faster in coverage. They are applied in warehouse floors, factories, and parking decks.

Key Features

Here are some key features of power trowel. Such as:

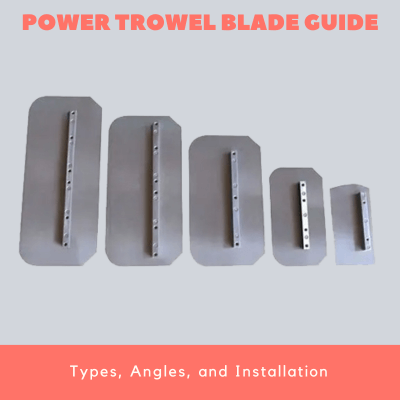

- Adjustable Blades

Blade pitch can be changed during use. Flat blades are used first. Steeper angles are used later for a harder finish.

- Engine Power

Power trowels have gas, diesel, or electric engines. Walk-behind models have less power. Ride-on types have more. Stronger engines finish faster and handle bigger jobs.

- Blade Speed and Rotation

Blades spin at 60–150 RPM. Slower speeds are for early passes. Faster speeds give a glossy, dense finish.

Advantages of Power Trowels

Power trowels are beneficial for the following purposes:

- Efficiency and Speed for Large Projects

Power trowels finish concrete fast. What takes hours by hand takes minutes with a machine.

- Consistent, Smooth Finishes

The blades apply even pressure. This gives a clean, polished look every time. It helps with floor coatings and paint later.

- Less Physical Strain on the Operator

The machine does the hard work. Operators don’t need to bend or kneel. Ride-on trowels are even easier—they just steer.

What is a Concrete Hand Trowel

Now let’s discuss the concrete hand trowel in detail.

A concrete hand trowel is a basic finishing tool. It is applied to fill and flatten minor surfaces of concrete. It is a flat metal blade, and the tool is supplied with a handle.

They apply it by hand to press, form, and shape and polish the surface of the concrete. The hand trowels are prevalent in small-scale or detailed work. They are required in the finishing of areas where the machines are unable to get to. Often these are edges, corners, and narrow openings.

Key Features

Some prominent features of concrete hand trowel are as below:

- Lightweight Design

Hand trowels are easy to carry and use. The lion of them is composed of lightweight metals such as aluminum or stainless steel. Their miniature size renders them ideal for making precision work.

- Ergonomic Handle

The handle is shaped for comfort. It gives better grip and reduces strain during long jobs. Many trowels have soft, rubber-coated handles for extra control.

- Blade Material and Shape

Blades are usually made of steel or carbon. Some are stainless for better rust resistance. The blade’s shape matters. For example, rounded edges are used for smooth finishes, while pointed edges help reach tight corners.

Advantages of Hand Trowels

Hand trowels provide the following advantages:

- Precision for Small Jobs

Hand trowels give fine control. They’re perfect for fixing small patches or finishing narrow spaces. You can smooth around pipes, drains, or walls with accuracy.

- More Control for Detail Work

You can put the pressure where necessary using a hand trowel. It is perfect in decorative finishing and curving and stamped concrete edges.

- Lower Initial Cost

Hand tools are much cheaper than machines. They do not require fuel or maintenance. They are affordable in the case of a DIY project or of a small concrete job.

Key Differences Between Power Trowel and Hand Trowel

We have briefly discussed the both – power trowel and hand trowel. Let’s have a deep look on key differences.

Speed and Efficiency

A power trowel is built for speed. It covers large areas quickly. It’s ideal for commercial slabs and factory floors. A hand trowel is slower. But it’s perfect for tight spots, corners, and touch-ups.

Level of Skill Required

Operating a power trowel needs training. It’s a heavy machine. Incorrect use can lead to surface damage or injury. A hand trowel is easier to use. Even beginners can pick it up and start smoothing concrete.

Finish Quality

Power trowels produce glossy, even finishes. They apply consistent pressure over wide areas. Hand trowels offer better control for edges and decorative work. They’re used for details machines can’t reach.

Cost and Investment

A power trowel is a big investment. It costs more but saves time on big jobs. Long-term, it’s cost-effective for professionals. A hand trowel is cheap and simple. It’s perfect for homeowners and small contractors.

When to Use a Power Trowel

For using a power trowel, here are some ideal use cases as:

Ideal Use Cases

- Large commercial or industrial projects: Power trowels are designed for scale. They cover large concrete surfaces efficiently. They are used by warehouses, factories, and commercial stores. They are familiar for the construction why have deadline.

- High-volume concrete pours: Power trowels handle wide slabs with ease. They prevent cold joints in large pours. Their speed ensures uniform curing.

- Floors requiring high-quality, uniform finish: If a polished, smooth surface is required, choose a power trowel. They deliver professional-grade results. Ideal for showrooms, garages, and commercial floors.

Why Choose a Power Trowel for These Jobs

Using power trowel for above-mentioned purpose is beneficial because:

- Efficiency in large spaces: In relation to large areas, a power trowel can be used to complete a 1,000 sq. ft. within less than one hour. This is time consuming as opposed to manual equipment.

- Lesser time and labor cost: Less number of workers is sufficient to lay a slab. Fast results lower overall project costs. Less fatigue means more productivity.

- Consistent results over large areas: Power trowels maintain even blade pressure. This gives a uniform finish across the entire floor. No risk of uneven patches or tool marks.

When to Use a Hand Trowel

Hand trowels are best suitable to use in the following cases:

Ideal Use Cases

- Small residential projects: Hand trowels are perfect for driveways, patios, and small floors. DIYers and contractors use them for tight spaces. They’re suitable for projects needing precision over speed.

- Touch-ups on edges and corners: Power tools can’t reach all areas. Hand trowels work well along walls, edges, and around fixtures. They’re perfect for detailed corrections and smoothing.

- Decorative finishes requiring precise control: Stamped or textured concrete needs precision. Hand trowels let you shape and smooth with care. You can apply artistic or textured designs easily.

Why Choose a Hand Trowel for These Jobs

Here are the reasons why hand trowel is best for the above use cases

- Greater control for smaller areas: You guide every movement with your hand. This offers better accuracy and less chance of overworking the surface.

- Better for finishing around obstacles (pipes, posts, etc.): Hand trowels fit in spaces machines can’t. They work around corners, rebar, and irregular shapes. You can apply exact pressure in tight spots.

- Easier to carry and maneuver: Hand trowels are lightweight and portable. They require no fuel or electricity. You can start immediately without setup.

Power Trowel vs Hand Trowel: Pros and Cons Comparison Table

To have a clearer idea of the comparison of these tools, here is a table of summary:

| Feature | Power Trowel | Hand Trowel |

| Speed | Very fast and efficient for large areas | Slower, requires more time and effort |

| Finish Quality | Smooth, consistent, and professional | Great for detail work, but less uniform on large slabs |

| Cost | High upfront cost, but labor savings on big jobs | Low cost, ideal for small-scale or one-time projects |

| Ease of Use | Requires skill and training | Simple to use, beginner-friendly |

| Maintenance | Requires regular engine and blade maintenance | Minimal—clean after use and store properly |

In this comparison, the decision can be made based on different facts. These are the size of a project, finishing objectives, and user experience.

These two tools perform best under varied circumstances. Each tool excels under different conditions.

Choosing the Right Tool for Your Project

In choosing between power trowel and hand trowel the following may be noted:

- Project Size: For large surfaces, a power trowel saves time. Fin tight, or small spaces, use a hand trowel.

- Budget: A power trowel is costly in its initial cost but saves the money later. A hand trowel does not cost as much initially.

- Desired Finish: A wide slab needs a power trowel to produce a mirror-smooth finish. Hand trowels are superior to give extra fit or fine.

- Skill Level: Hand trowels are less demanding when you do not have training and experience.

Case Examples:

- A DIY homeowner working on a backyard patio may choose a hand trowel.

- A contractor pouring a warehouse floor would benefit from a ride-on power trowel.

Safety Considerations for Using Both Trowels

Safety of Power Trowel:

Personal protective equipment (PPE) should be used always. It covers hearing protection, gloves and boots. Operators should be trained in machine handling. The work area must be free of obstacles to prevent accidents.

Hand Trowel Safety:

Wear gloves to avoid getting blisters and to reduce the fatigue due to holding the trowel. Maintain a proper posture to prevent a backache. Handle the tool carefully to avoid injury from sharp edges.

Conclusion

Concrete finishing can take place with power and hand trowels. Large projects need power trowels because of their speed and uniformity. Nonetheless, hand trowels resemble accuracy and low costs in case of minor jobs.

The project size, budget, and finish when done will determine the best tool to take. In applying these tools, you can always expect it to turn out well and professionally in each instance.

FAQs

Can I use a hand trowel for large concrete projects?

Yes but that will take a log time and probably have uneven finishes.

How long does it take to finish a concrete floor with a power trowel?

It does not rely on the size. A power trowel can produce large slabs within a very small portion of time as compared to manual tools.

What are the maintenance costs of a power trowel?

They vary but include regular engine servicing, blade replacements, and fuel.

Can a hand trowel achieve the same finish as a power trowel?

In such small areas, yes. However, on massive slabs, the power trowels provide more uniform and professional finishes

Leave A Comment