Power Trowel Fails: Top 7 Mistakes You Need to Avoid

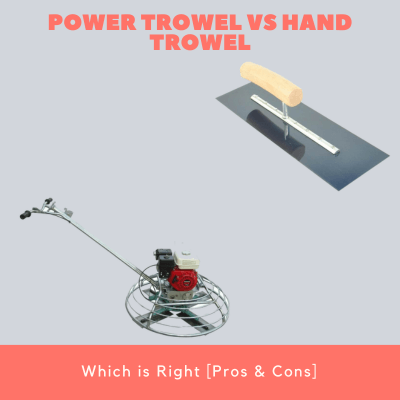

Power trowels are valuable tools used in the construction industry for achieving smooth and durable concrete surfaces. However, without proper knowledge and technique, operators may fall into common mistakes that can compromise the quality of their work.

In this post, we will explore the top 7 mistakes to avoid when using power trowels. By understanding and preventing these errors, operators can enhance their troweling skills, improve efficiency, and ensure exceptional results in their concrete finishing projects.

Importance of power trowels

- Power trowels are essential tools for achieving smooth and level concrete surfaces in construction projects.

- They improve efficiency, save time, and enhance the overall quality of the finished concrete.

Common mistakes

- Despite their benefits, power trowels can lead to undesirable outcomes if not used correctly.

- It is crucial to be aware of the common mistakes that can occur during power trowel operation to avoid costly errors and achieve optimal results.

Contents

Lack of Proper Training

Importance of training and experience

- Operating a power trowel requires proper training to understand its functionalities, safety protocols, and techniques.

- Inadequate training increases the risk of mistakes, accidents, and subpar results.

Consequences of operating without proper training

- Inefficient use of the power trowel, leading to inconsistent finishes, uneven surfaces, or unnecessary wear and tear.

- Increased risk of accidents or injuries due to improper handling or lack of knowledge about safety measures.

Solutions: Training programs, hiring skilled operators

- Encourage operators to undergo training programs or certification courses specific to power trowel operation.

- Consider hiring skilled and experienced operators who are familiar with power trowel techniques and safety procedures.

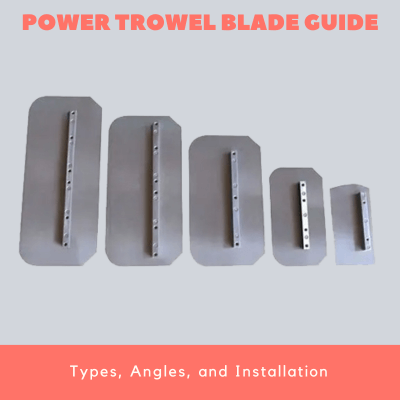

Incorrect Blade Angle Adjustment

Impact of incorrect blade angle on concrete surface

- Incorrect blade angle can result in uneven finishes, surface imperfections, or insufficient compaction.

- It can cause variations in concrete thickness, leading to weak spots and compromised durability.

Common errors in blade angle adjustment

- Setting the blade angle too low can result in excessive material removal, causing rough surfaces or premature wear on the blades.

- Setting the blade angle too high may lead to inadequate compaction and a lack of desired smoothness.

Importance of maintaining the correct blade angle

- Proper blade angle ensures optimal contact between the trowel blades and the concrete surface, resulting in consistent compaction and finish.

- It helps achieve the desired levelness, smoothness, and density of the concrete.

Solutions: Checking and adjusting blade angle regularly

- Regularly inspect and adjust the blade angle according to manufacturer guidelines and project requirements.

- Utilize tools such as angle gauges or laser levels for precise blade angle adjustment.

- Train operators to understand the importance of maintaining the correct blade angle and provide them with the necessary tools and resources for accurate adjustments.

Improper Blade Pitch Adjustment

Effects of incorrect blade pitch on troweling performance

- Incorrect blade pitch can result in inadequate concrete compaction, leading to weak spots and reduced durability.

- Improper blade pitch can also cause surface imperfections, such as ridges or swirl marks.

Common mistakes in blade pitch adjustment

- Setting the blade pitch too low may lead to insufficient compaction and a lack of desired smoothness.

- Setting the blade pitch too high can cause excessive material removal, resulting in an uneven finish.

Importance of achieving optimal blade pitch

- Optimal blade pitch ensures proper compaction of the concrete, enhancing its strength and durability.

- It helps achieve a uniform and smooth surface, improving aesthetics and functionality.

Solutions: Understanding blade pitch settings, adjusting as needed

- Familiarize operators with the recommended blade pitch settings based on the specific concrete mix and project requirements.

- Regularly inspect and adjust the blade pitch during trowel operation to maintain optimal performance.

- Train operators to monitor the concrete surface and make necessary adjustments to the blade pitch to achieve the desired finish.

Over-Troweling

Negative effects of excessive troweling

- Over-troweling can lead to surface damage, such as surface cracking, scaling, or delamination.

- Excessive troweling can result in an overly smooth surface that lacks the necessary texture for proper bonding with subsequent coatings or finishes.

Signs of over-troweling

- Burnishing or polishing of the concrete surface beyond the desired finish.

- Appearance of surface defects, including fine cracks or a glossy sheen.

- Difficulty in achieving proper curing or subsequent surface treatments due to a tightly compacted surface.

Importance of proper timing and monitoring

- Proper timing is crucial to achieve the desired concrete finish without over-troweling.

- Regular monitoring of the concrete surface during troweling helps identify signs of over-troweling and take corrective action.

Solutions: Knowing when to stop troweling, allowing for proper curing

- Train operators to recognize the signs of over-troweling and understand the importance of proper timing.

- Set clear guidelines for when to stop troweling based on project specifications and concrete mix properties.

- Allow sufficient time for proper curing after troweling to ensure adequate strength development and surface durability.

Inadequate Control of Machine Speed

Impact of incorrect machine speed on troweling results

- Incorrect machine speed can result in an uneven concrete finish, with variations in surface texture and compaction.

- Inadequate control of machine speed can lead to surface imperfections, such as streaks, ridges, or uneven trowel marks.

Common errors in controlling machine speed

- Operating the trowel machine at a consistently high speed can lead to overworking the concrete and creating an overly smooth surface.

- Inconsistently adjusting the machine speed during troweling can cause variations in the surface texture and compaction.

Importance of adjusting machine speed appropriately

- Proper control of machine speed allows for consistent and uniform troweling, resulting in a smooth and even concrete finish.

- Adjusting the machine speed based on the concrete mix properties, ambient conditions, and desired finish helps optimize troweling results.

Solutions: Understanding machine speed settings, practicing control

- Familiarize operators with the recommended machine speed settings for different concrete mixes and project requirements.

- Train operators to adjust and maintain a consistent machine speed during troweling to achieve the desired finish.

- Practice controlling the machine speed by maintaining a steady and controlled movement while troweling the concrete.

Ignoring Maintenance and Inspection

Importance of regular maintenance and inspection

- Regular maintenance and inspection ensure the proper functioning and longevity of the power trowel.

- Maintenance helps identify and address potential issues before they escalate into major problems, reducing downtime and repair costs.

Consequences of neglecting maintenance

- Neglecting maintenance can lead to equipment breakdowns, decreased performance, and increased risk of accidents or injuries.

- Lack of regular inspection can result in undetected damages or wear that may compromise the trowel’s efficiency and safety.

Commonly overlooked maintenance tasks

- Failure to clean the trowel after each use, leading to the buildup of hardened concrete or debris.

- Ignoring lubrication of moving parts, resulting in increased friction and potential damage.

- Neglecting to check and replace worn or damaged blades, affecting troweling performance and concrete finish.

Solutions: Following manufacturer’s guidelines, establishing maintenance routine

- Adhere to the manufacturer’s recommended maintenance schedule and guidelines for the power trowel.

- Establish a routine maintenance plan that includes cleaning, lubrication, blade inspection, and replacement as needed.

- Train operators on proper maintenance procedures and encourage their active participation in equipment upkeep.

Lack of Personal Protective Equipment (PPE)

Importance of wearing PPE during troweling operations

- Wearing proper PPE is crucial to protect operators from potential hazards and ensure their safety during power trowel use.

- PPE safeguards against injuries from flying debris, concrete splatter, noise exposure, and respiratory hazards.

Consequences of neglecting PPE

- Neglecting PPE can result in injuries such as eye injuries, respiratory problems, hearing damage, and physical harm from concrete debris.

- Without appropriate PPE, operators are at a higher risk of accidents and long-term health issues.

Essential PPE for power trowel operators

- Safety glasses or goggles to protect the eyes from debris and chemicals.

- Ear protection such as earmuffs or earplugs to minimize the impact of loud noise.

- Respiratory protection, such as dust masks or respirators, to prevent inhalation of harmful dust and fumes.

- Safety gloves and boots to protect the hands and feet from potential hazards.

Solutions: Providing proper PPE, enforcing safety protocols

- Ensure that operators have access to and are trained on the proper use of appropriate PPE.

- Establish and enforce strict safety protocols that require the use of PPE during power trowel operations.

- Regularly inspect PPE to ensure its quality and functionality, and replace any damaged or worn-out equipment.

Conclusions

In conclusion, avoiding common power trowel mistakes is crucial for achieving high-quality results in concrete finishing projects. By addressing issues such as lack of training, improper blade adjustment, over-troweling, and inadequate maintenance, operators can ensure smooth and durable surfaces.

Additionally, wearing proper personal protective equipment and controlling machine speed are essential for operator safety and project success. Continuous learning and improvement in power troweling techniques will lead to enhanced productivity and better outcomes.

By avoiding these mistakes and focusing on skill development, operators can maximize efficiency, minimize errors, and deliver top-notch results in their construction projects.

Leave A Comment