How to Power Trowel Concrete: Step-by-Step [Beginner to Pro]

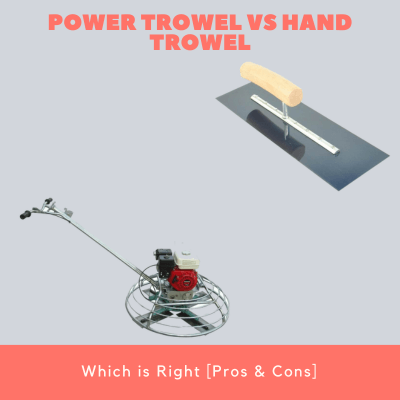

Power troweling is a fundamental technique in the realm of concrete finishing. It involves using a power-driven machine with rotating blades to achieve a smooth, level, and polished surface on a freshly poured concrete slab. Proper power troweling is crucial for enhancing the strength, durability, and aesthetics of the concrete.

Whether you are a beginner or a seasoned professional, understanding the step-by-step process and considerations involved in power troweling is essential to achieve the best results.

Brief explanation of power troweling

- Power troweling is a technique used in the final stages of concrete finishing.

- It involves the use of a power-driven machine with rotating blades to flatten and compact the concrete.

- The machine’s blades create a smooth and polished surface on the concrete slab.

Importance of properly power troweling a concrete slab

- Ensures a level and even surface, minimizing imperfections and unevenness in the concrete.

- Increases the density and strength of the concrete by compressing the surface and reducing porosity.

- Enhances the durability and longevity of the concrete slab.

- Provides a visually appealing finish, especially for exposed concrete surfaces.

Contents

Preparing for Power Troweling

Ensuring the concrete slab is properly cured

- Before power troweling, it is crucial to allow the concrete slab to cure sufficiently.

- Follow the recommended curing time provided by the concrete supplier or as per industry standards.

- Proper curing ensures that the concrete has gained sufficient strength and hardness for troweling.

Gathering the necessary tools and equipment

- Gather all the essential tools and equipment needed for power troweling.

- This typically includes a power trowel machine, blades, safety gear (gloves, safety glasses, hearing protection), and any additional hand tools for detailing or edging.

Checking the weather conditions

- Weather conditions can significantly affect the power troweling process and the quality of the concrete finish.

- Avoid power troweling in extreme heat, direct sunlight, or strong winds, as they can cause the concrete to dry too quickly or affect the machine’s operation.

- Ideally, perform power troweling in moderate temperatures and mild weather conditions for optimal results.

Setting up the Power Trowel

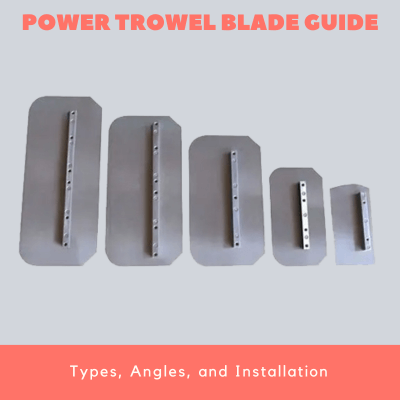

Choosing the right trowel blades for the job

- Select trowel blades that are appropriate for the type of concrete and the desired finish.

- Consider factors such as blade size, shape (combination, float, or finish), and blade material.

- Different blade options are available to achieve specific finishes, such as smooth, medium, or heavy-textured surfaces.

Adjusting the pitch and speed of the power trowel

- Set the pitch of the trowel blades to achieve the desired angle of attack.

- Adjust the pitch according to the manufacturer’s instructions and the specific requirements of the project.

- Additionally, adjust the speed of the power trowel to maintain control and achieve the desired finish.

Inspecting and preparing the power trowel machine

- Before starting the power trowel, inspect it for any damage or loose parts.

- Ensure that the machine is clean, well-maintained, and properly lubricated.

- Check the engine oil and fuel levels, and make sure the machine is in good working condition.

Power Troweling Techniques

Starting the power trowel and maintaining control

- Stand behind the power trowel, ensuring a firm grip on the handles.

- Start the engine following the manufacturer’s instructions.

- Gradually increase the speed to the desired operating level while maintaining control over the machine.

First pass: Floating the concrete surface

- Adjusting the blade angle and pressure:

- Set the blade angle to a slightly positive pitch to achieve a floating action.

- Apply light pressure on the trowel to prevent digging into the concrete surface.

- Overlapping the passes for even coverage:

- Move the power trowel in parallel lines, overlapping each pass by around 50% to ensure even coverage across the entire surface.

Second pass: Smoothing the surface

- Adjusting the blade angle and pressure for a smoother finish:

- Gradually increase the blade pitch to create a smoother finish.

- Apply slightly more pressure than in the floating pass to further densify the surface.

- Overlapping the passes to eliminate lines and imperfections:

- Continue moving the power trowel in parallel lines, overlapping each pass by approximately 75% to eliminate any visible lines or imperfections.

Third pass: Finishing the surface

- Using the power trowel to achieve the desired texture:

- Adjust the blade pitch to achieve the desired texture, such as a smooth or textured finish.

- Apply consistent pressure to achieve a uniform texture across the surface.

- Consistently overlapping the passes for uniformity:

- Maintain a consistent walking pace while overlapping each pass by at least 90% to ensure a uniform finish.

Safety Considerations

Wearing appropriate personal protective equipment (PPE)

- Always wear the necessary PPE, including safety glasses, gloves, hearing protection, and steel-toed boots.

- PPE helps protect against potential hazards such as flying debris, noise, and injuries.

Being mindful of power trowel operation hazards

- Be aware of the rotating blades and the potential for entanglement or contact injuries.

- Keep hands and clothing away from moving parts.

- Avoid operating the power trowel near others to prevent accidents or injuries.

Ensuring a clean and organized work area

- Remove any tripping hazards, debris, or objects that could interfere with the power trowel’s operation.

- Keep the work area clean and organized to prevent accidents and promote a safe working environment.

Finishing Touches and Clean-Up

Checking the surface for imperfections

- After completing the power troweling process, inspect the concrete surface for any imperfections or inconsistencies.

- Look for areas that may require additional attention or touch-ups.

Making necessary adjustments or corrections

- If you identify any imperfections, make the necessary adjustments or corrections to achieve the desired finish.

- Use hand tools or additional troweling techniques to address any specific areas that need refinement.

Cleaning and maintaining the power trowel equipment

- Thoroughly clean the power trowel after use to remove any concrete residue and prevent build-up.

- Follow the manufacturer’s guidelines for cleaning and maintenance, including lubricating moving parts and ensuring proper storage.

Properly disposing of waste materials

- Dispose of any waste materials, such as excess concrete or debris, in accordance with local regulations and guidelines.

- Avoid dumping concrete or waste materials into storm drains or other environmentally sensitive areas.

Conclusions

In conclusion, proper power troweling is crucial for achieving high-quality concrete slabs. By following the steps and considerations outlined in this post, including preparation, technique, safety, and clean-up, you can ensure a level, durable, and visually appealing finish. Continual practice and refinement of power troweling skills will lead to improved results.

Remember to prioritize safety and maintain a clean work environment throughout the process. With dedication and attention to detail, you can master the art of power troweling and achieve outstanding concrete finishes.

Leave A Comment