Manual vs Pneumatic vs Vibratory Hand Earth Rammer: Which is Best

A hand earth rammer is a simple and effective non-mechanized earth ramming tools. It consists of a long handle and a heavy metal head. The head of the rammer is usually made of cast iron or steel and is shaped like a flat circular plate with a diameter ranging from 6 to 10 inches. The handle is usually made of wood, metal or fiberglass and is designed to be comfortable and easy to grip.

The operation of a hand earth rammer entirely depends on human effort. The operator lifts the rammer by its handle and brings it down forcefully to exert compaction force on the soil. This process is repeated until the required compaction is achieved.

Hand earth rammers are critical in compaction over small areas. They come with several advantages over mechanized rammers. Firstly, hand earth rammers do not require technical skills to operate. This implies that once has access to a huge supply of operators; lowering labor costs. The absence of an engine makes hand earth rammers pollution free. For this reason, they can be used in tight spaces and areas such as hospitals; where noise and air pollution are prohibited.

Contents

Manual Hand Earth Rammer

A manual hand earth rammer consists of a long shaft with a heavy flat metal plate attached to one end. This rammer uses the weight of the metal plate to exert pressure on the material under compaction. The user lifts the rammer by its shaft and drops onto the surface under compaction. The dropping force and weight of the metal plate exert a force onto the soil to compact it. The process is repeated until the right density is achieved.

The absence of an external power source makes the manual hand earth rammer a cost-effective compaction tool. The rammer doesn’t have an engine or motor; therefore, users don’t incur power and fuel costs. This rammer is lighter and portable compared to other mechanized rammers. It is ideal for projects in remote areas where access to fuel and power is limited. Manual hand earth rammers do not produce noise and fumes. This makes them ideal for compaction in tight spaces and in areas such as schools where noise pollution is prohibited.

The main disadvantage of hand earth rammers is fatigue to the user especially when used over a long time. Lifting the rammer and dropping to compact soil requires a lot of physical energy. The drops when using a hand earth rammer do not generate a uniform impact. This results to inconsistency when the rammer is used over a large area.

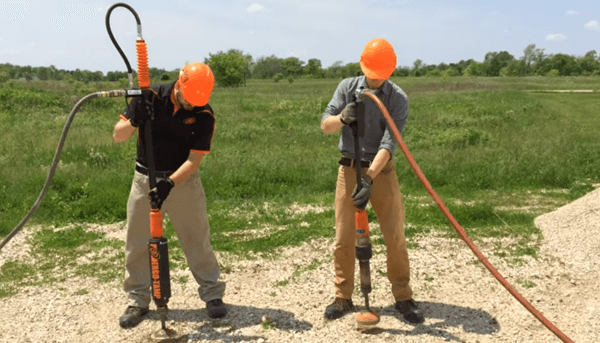

Pneumatic Hand Earth Rammer

A pneumatic hand earth rammer uses compressed air to deliver impact on the material under compaction. This rammer is made up of a heavy metal plate attached to a long metal shaft. A hose connected to the air compressor delivers compressed air to the plate resulting in a compacting force.

The heavy metal plate on the pneumatic hand earth rammer is lifted and dropped on the material under compaction by air-driven pistons. The compressed air generates high frequency vibrations that amplify the compaction effect.

The main advantage of a pneumatic hand earth rammer is that it is much faster and easier to use than a manual hand earth rammer. Fatigue is minimized on the user since the lifting and dropping of the heavy metal plate is done by the rammer itself. The vibrations caused by air pressure can be adjusted to suit compaction needs. Therefore, the rammer can be used for a variety of projects that require different degrees of compaction. With this rammer, a more consistent degree of compaction can be attained by adjusting the vibrations to required standards. Portability of the pneumatic hand earth rammer makes it ideal in remote areas. The rammer also produces minimal noise and fumes; therefore, it can be used in tight areas that require silence.

Need for an external source of power makes the pneumatic hand earth rammer less advantageous compared to the manual hand earth rammer. Elements such as the air compressor are expensive to buy and maintain in case of breakdowns. The vibrations generated by this rammer could cause discomfort to the operator. However; modern pneumatic hand rammers are designed with dampers to minimize vibrations on the user.

Vibratory Hand Earth Rammer

A vibratory hand earth rammer consists of a metal plate mounted on a vibrating mechanism. It is powered by a gasoline or diesel engine. The user holds the handle and guides the plate over the surface being compacted. The rammer uses high frequency vibrations to compact material into a denser state. The metal plate; in contact with the material under compaction, vibrates causing the material to settle.

The main advantages of using a vibratory hand earth rammer are that it can be used to compact a large area, its fast and more efficient. The vibration frequency can be adjusted to suit the compaction needs. This makes the rammer ideal for a wide variety of projects that need different degrees of compaction. Since its engine is diesel or gasoline powered, the vibratory hand earth rammer can be used in remote areas where power connection is unavailable. It is fairly portable and can be transported from one site to another easily.

The main disadvantage of vibratory hand earth rammers is that they are difficult to maneuver in tight spaces. Additionally, the fumes produced by the engine make it difficult for operations in areas with minimal ventilation. Noise produces by the running engine causes disturbance in areas such as schools and hospitals. For vibratory hand earth rammers with insufficient damping, the user might suffer extreme fatigue due to vibrations while operating the rammer. The weight of the rammer and its vibration makes it difficult to operate over uneven terrains.

Comparison of Hand Earth Rammers

The various hand earth rammers compare differently from each other. The comparisons could be used to determine which rammer is ideal for a certain project. The criteria for comparison of rammers is based on efficiency, cost, ease of use, and maintenance. These are further discussed below.

- Efficiency

Manual hand earth rammer is the least efficient of the three types. It requires more effort and time to compact the material. Manual hand earth rammers entirely depend on human effort which could be inconsistent. Pneumatic and vibratory hand earth rammers are more efficient, with the vibratory type being the most efficient due to its high-frequency vibration.

- Cost

Manual hand earth rammer is the most affordable option, as it does not require any power source or additional equipment. Pneumatic hand earth rammer requires an air compressor and hoses, which can be expensive. Vibratory hand earth rammer is the most expensive option, as it requires a gasoline or diesel engine.

- Ease of use

Manual hand earth rammer requires more physical effort and may cause fatigue, making it less easy to use. Pneumatic hand earth rammer is easier to use than the manual type, as it requires less physical effort. Vibratory hand earth rammer is the easiest to use, as it is powered by an engine and requires minimal physical effort. The manual earth rammer is the most portable due to its weight and size. The pneumatic and vibratory hand rammers are heavier and require careful handling. This makes them less easy to transport.

- Maintenance

Manual hand earth rammer requires minimal maintenance, as it has no moving parts. Pneumatic hand earth rammer requires regular maintenance of the air compressor and hoses. Vibratory hand earth rammer requires regular maintenance of the engine and vibrating mechanism.

Conclusion

Each type of hand earth rammer – manual, pneumatic, and vibratory – has its own advantages and disadvantages. Manual hand earth rammer is the most affordable and portable option, but it is less efficient and requires more physical effort. Pneumatic hand earth rammer is easier to use than the manual type, but it requires an external power source and regular maintenance of the air compressor and hoses. Vibratory hand earth rammer is the most efficient, requiring minimal physical effort, but it is also the most expensive and least portable, and requires regular maintenance of the engine and vibrating mechanism.

Choosing the best hand rammer should be guided by the size of the project, the type of material being compacted, and the availability of the rammer. For smaller projects, a manual hand earth rammer may be the most practical and cost-effective option. For larger projects, a pneumatic or vibratory hand earth rammer may be more efficient and practical.

Leave A Comment