Boosting Bar Bender Productivity: 5 Factors and 6 Methods

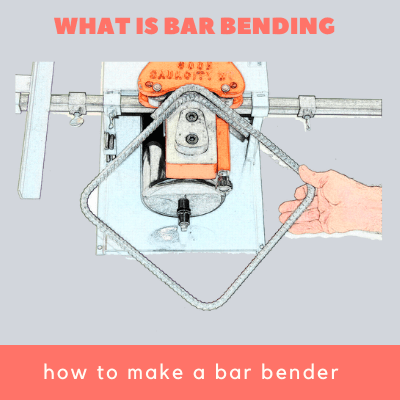

Bar Bending: A Pillar of Construction Excellence. Discover the definition and crucial role of bar bending in construction. Explore the importance of measuring bar bender productivity per day to optimize efficiency and ensure successful project completion.

Contents

Factors Affecting Bar Bender Productivity

Bar bender productivity can be influenced by various factors that impact their efficiency and output:

A. Experience and skill level of bar bender

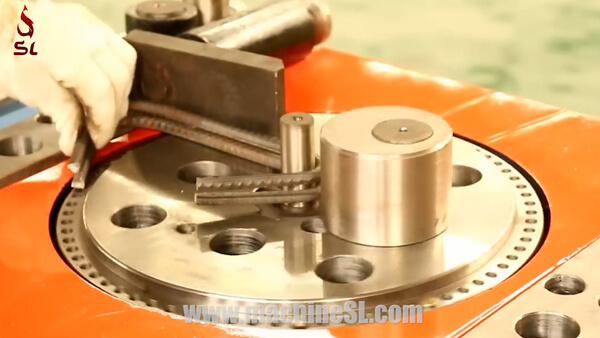

Highly experienced and skilled bar benders can work more swiftly and accurately, bending and shaping reinforcement bars with precision, thereby increasing productivity.

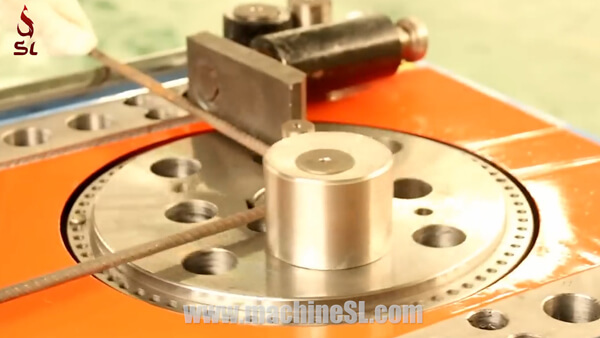

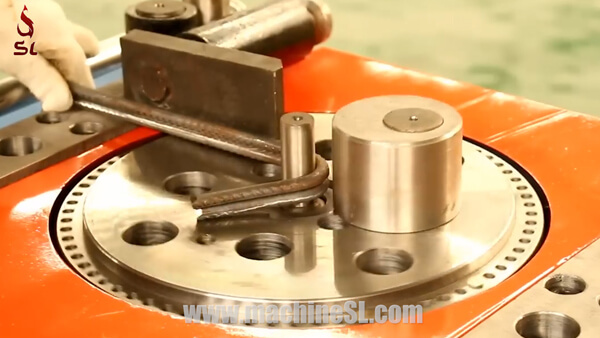

B. Availability and suitability of tools and equipment

Adequate and well-maintained tools, such as rebar benders and cutters, are essential for smooth and efficient bar bending. Having the right equipment ensures tasks can be completed in a timely manner.

C. Work environment conditions

Favorable work conditions, such as proper lighting, ventilation, and space, contribute to higher productivity, enabling bar benders to work comfortably and with focus.

D. Complexity and scale of the construction project

Larger and more complex projects may present challenges that affect productivity. Detailed and intricate reinforcement requirements may require additional time and attention.

E. Communication and coordination with other team members

Effective communication and coordination among construction professionals, including engineers and steel fixers, help streamline the workflow, minimizing delays, and enhancing overall productivity.

Methods for Measuring Bar Bender Productivity

Measuring bar bender productivity is crucial for construction project management and resource optimization. Various methods can be employed for this purpose:

A. Time-based productivity measurement

- Calculating the number of bars bent per hour/day: Tracking the quantity of reinforcement bars bent within a specific time frame provides a clear measure of the bar bender’s output and efficiency.

- Assessing the time taken for each bar bending task: Recording the time spent on individual bending tasks helps identify potential bottlenecks and areas for improvement.

B. Quantity-based productivity measurement

- Evaluating the total length of bars bent per day: Measuring the total length of reinforcement bars bent in a day provides an overall assessment of productivity, considering both quantity and complexity of bends.

- Tracking the number of different types of bends made: Monitoring the variety of bends performed gives insight into the bar bender’s versatility and ability to handle diverse requirements.

C. Quality-based productivity measurement

- Inspecting the accuracy and precision of bent bars: Regular quality checks on the bent bars ensure that the work meets required tolerances and specifications.

- Evaluating the adherence to project specifications and standards: Assessing how well the bar bender follows construction drawings and project guidelines helps gauge productivity in terms of meeting project requirements.

- By utilizing these methods, construction companies can obtain valuable data on bar bender productivity, identify areas of improvement, and make informed decisions to enhance efficiency, reduce errors, and optimize resource allocation in construction projects.

Strategies to Improve Bar Bender Productivity

To enhance bar bender productivity, construction companies can implement the following strategies:

A. Training and skill development programs

Invest in specialized training to improve bar benders’ knowledge and proficiency in bending techniques and equipment usage, leading to increased efficiency and accuracy.

B. Efficient work planning and task scheduling

Develop well-organized work plans and schedules that consider the sequence of bar bending tasks, ensuring timely completion and minimal downtime.

C. Effective communication and coordination within the construction team

Foster clear communication channels among team members, including engineers, steel fixers, and other trades, to streamline the workflow and prevent delays or misunderstandings.

D. Regular maintenance and upgrade of tools and equipment

Ensure that bar benders have access to well-maintained and up-to-date tools, such as rebar benders and cutters, to maximize their productivity and safety.

E. Provision of a safe and comfortable work environment

Prioritize safety and create a conducive work environment that minimizes distractions and discomfort, enabling bar benders to focus on their tasks with efficiency.

F. Implementation of productivity tracking systems

Employ productivity tracking tools or software to monitor and analyze bar bender performance, identifying strengths and areas for improvement, and optimizing resource allocation.

By adopting these strategies, construction companies can boost bar bender productivity, optimize project timelines, and enhance the overall efficiency and success of construction projects. A motivated and skilled bar bending team contributes significantly to the smooth execution of concrete structures, ensuring their durability and structural integrity.

Case Studies or Examples

A. Real-life examples showcasing successful productivity improvement initiatives

Construction Company X implemented a comprehensive training program for their bar benders, focusing on advanced bending techniques and the proper use of equipment. They also introduced a productivity tracking system to monitor daily output. As a result, the bar benders’ bending speed increased by 20%, and their accuracy improved, reducing the need for rework. This initiative significantly contributed to the completion of a large infrastructure project ahead of schedule.

B. Analysis of the strategies employed and their impact on bar bender productivity

In Example, the focus on training and skill development improved the bar benders’ bending techniques and efficiency, leading to faster bending speeds and higher accuracy. The introduction of the productivity tracking system allowed for data-driven decision-making and identified areas where additional training and support were needed. The overall impact of these initiatives was evident in the successful early completion of the project, saving time and costs for Construction Company X.

Conclusions

Measuring bar bender productivity per day is crucial for construction project management. It provides valuable data on output and efficiency, enabling companies to optimize resources, identify areas for improvement, and ensure timely project completion. Several factors impact bar bender productivity, including experience, tools, work environment, project complexity, and communication. Recognizing and addressing these factors is essential for enhancing productivity.

Implementing strategies for productivity improvement, such as training, efficient planning, and communication, can significantly enhance bar bender efficiency. These initiatives not only benefit the construction process but also contribute to a safer and more productive work environment. Looking to the future, advancements in technology and construction methods will likely influence bar bending productivity. Companies that invest in innovative tools and training will have a competitive edge in the evolving construction industry.

Leave A Comment