Step-by-Step Tutorial: How to Bend Rebar in a Circle by Machine

Rebar, short for reinforcing bar, is a steel bar or mesh of steel wires used as a tension device in reinforced concrete and reinforced masonry structures. It is used to provide additional strength and support to concrete structures, such as buildings, bridges, highways, and dams.

Bending rebar is an essential part of the construction process when using reinforced concrete. The importance of bending rebar lies in the fact that it allows for the creation of intricate shapes and designs in the concrete, while also providing the necessary strength and support to the structure.

Using a machine to bend rebar can be an efficient and effective way to create accurate and consistent bends in large quantities of rebar.

Contents

Preparing the Rebar

Choosing the right rebar

Choosing the right rebar for bending in circle will depend on a variety of factors, including the specific requirements of the project, the bending radius, and the desired level of ductility and strength. It’s important to consult with an engineer or other qualified professional to ensure that the chosen rebar is suitable for the specific application.

Measuring the length of rebar needed

Measuring the length of rebar needed for circular bending requires careful planning and accurate calculations. It’s important to consult with an engineer or other qualified professional to ensure that the correct amount of rebar is ordered and used, and that the rebar is bent to the correct specifications.

Cleaning the rebar

Cleaning the rebar before bending is an important step to ensure that the rebar is free from dirt, rust, and other contaminants that could affect the quality of the bend or cause damage to the rebar.

Use a stiff bristle brush or compressed air to remove any loose debris, dirt, or rust from the surface of the rebar. This will help to ensure that the surface is clean and free from any contaminants that could affect the quality of the bend.

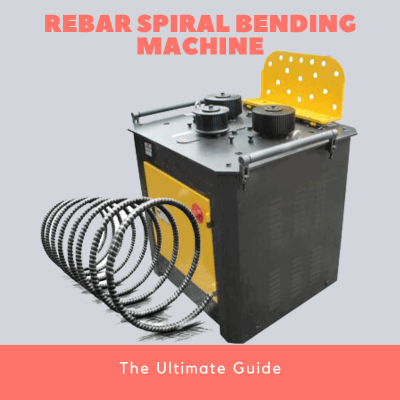

Setting up the Machine

Choosing the right machine

Choosing the right machine for rebar bending requires careful consideration of the specific requirements of your project, as well as factors such as capacity, speed, safety, and cost. It’s important to do your research and consult with experts to ensure that you choose a machine that meets your needs and provides the best possible results.

Some machines have automation features that can help to improve accuracy and efficiency, such as automatic feeding and cutting. Consider whether these features are important for your project.

Consider also the required bending angle for your project and make sure the machine can accommodate it. Some machines can only bend to a certain angle, while others are capable of bending to a wider range of angles.

The bending capacity of the machine should be able to accommodate the size and grade of the rebar you need to bend. Make sure to check the maximum bending capacity of the machine before purchasing.

Adjusting the machine to the correct settings

Adjusting the rebar bending machine to the correct settings is crucial to achieving accurate and precise bends in the rebar. Here are the basic steps for adjusting the machine to the correct settings:

- Check the machine manual: The first step is to check the machine manual to ensure that you understand the machine’s capabilities and specifications. This will help you to determine the correct settings for your specific rebar bending needs.

- Set the bending angle: Adjust the machine to the required bending angle. This may involve adjusting the bending pins or die set to ensure that the rebar is bent to the correct angle.

- Set the bending radius: Adjust the machine to the required bending radius for circles. This may involve adjusting the bending pins or die set to ensure that the rebar is bent to the correct radius.

- Adjust the feed rollers: Adjust the feed rollers to ensure that the rebar is properly fed into the machine and held securely during the bending process.

- Adjust the cutting mechanism: If the machine is capable of cutting the rebar to the required length, adjust the cutting mechanism to the correct length.

- Test the machine: Once the machine has been adjusted to the correct settings, test it with a sample piece of rebar to ensure that the bends are accurate and precise. Make any necessary adjustments before proceeding with the actual rebar bending.

It’s important to follow the manufacturer’s instructions and guidelines when adjusting the machine to ensure that it is set up correctly and operates safely. Additionally, it’s important to ensure that the machine is properly maintained and inspected regularly to prevent any issues or malfunctions during the bending process.

Ensuring safety measures are in place

Ensuring safety measures are in place when using a rebar bending machine is crucial to prevent accidents and injuries. Here are some safety measures to keep in mind when working with a rebar bending machine:

- Wear appropriate safety gear: Operators should wear appropriate safety gear, such as safety glasses, gloves, and protective clothing, to protect themselves from any potential hazards during the bending process.

- Ensure proper machine operation: Ensure that the machine is operating properly and is in good working condition before use. Inspect the machine regularly and perform any necessary maintenance to prevent any potential malfunctions.

- Install safety guards: Install safety guards around the machine to prevent operators from coming into contact with moving parts or other potential hazards.

- Use emergency stop buttons: Make sure that emergency stop buttons are easily accessible and that all operators know how to use them in case of an emergency.

- Train operators: Train all operators on how to safely use the rebar bending machine and ensure that they understand the potential hazards and safety measures to take.

- Follow proper lifting techniques: Use proper lifting techniques when handling rebar and ensure that the weight of the rebar is within the machine’s capacity.

- Keep work area clean: Keep the work area clean and free of clutter to prevent tripping hazards and other potential accidents.

Bending the Rebar

Bending rebar in a bending machine requires the following steps:

- Set up the machine: First, ensure that the bending machine is properly set up and adjusted to the correct settings as per the manufacturer’s instructions. Make sure that the bending pins or die set are adjusted to the required bending angle and radius.

- Feed the rebar: Feed the rebar into the machine, making sure that it is properly aligned with the bending pins. The feed rollers should be adjusted to ensure that the rebar is held securely during the bending process.

- Start the machine: Once the rebar is properly aligned, start the machine to begin the bending process.

- Monitor the bending process: Monitor the bending process closely to ensure that the rebar is properly bent to the required angle and radius. Use a measuring tool or gauge to check the angle and radius of the bends.

Finishing the Process

- Repeat the process: If additional bends are required, repeat the process by adjusting the bending pins or die set to the required angle and radius and feeding the rebar into the machine again.

- Cut the rebar: Once all required bends are complete, use the cutting mechanism of the machine to cut the rebar to the required length.

- Inspect the finished product: Inspect the finished product to ensure that the bends are accurate and precise, and the rebar is cut to the correct length.

Conclusions

In conclusion, using a bar bending machine can greatly improve the efficiency and accuracy of bending rebar. To ensure successful bending operations and minimize the risk of accidents or injuries, here are some final thoughts and tips:

- Select a machine that can handle the size and shape of rebar needed for the project.

- Follow the manufacturer’s instructions and guidelines for operating and maintaining the machine to ensure proper and safe operation.

- Always prioritize safety and ensure that all necessary safety measures are in place, such as proper machine operation, safety guards, emergency stop buttons, and proper lifting techniques.

- Choose high-quality rebar to ensure that it bends properly and produces accurate results.

- Thoroughly clean the rebar before bending to prevent any debris or rust from interfering with the bending process.

- Carefully monitor the bending process to ensure that the rebar is properly aligned and that the bends are accurate and precise.

- Regularly inspect the machine to ensure that it is in good working condition and perform any necessary maintenance to prevent malfunctions.

Leave A Comment