Top 4 Rebar Stirrup Bending Machines: Which Is Right for You

By employing the right stirrup bending machine, you can achieve the work of approximately 30 people, increasing efficiency and saving time.

Rebar stirrup machines, or bar bending machines, are specialized equipment designed for the construction industry. They bend or shape rebars into stirrups or hoops, with different types and sizes available, including manual and automated options.

This article introduces you to various stirrup bending machines, providing a comprehensive guide to their use, benefits, maintenance, and other essential information.

Contents

Benefits of Using Rebar Stirrup Bending Machine

Rebar stirrup bending machines offer numerous advantages for construction projects:

Increased efficiency and productivity

A stirrup bending machine significantly speeds up the bending process, reducing time and labor costs, ultimately leading to faster project completion. By eliminating the need for manual labor, you can increase the output of your construction project in a shorter amount of time. This increased efficiency allows you to take on more projects and grow your business.

Precise and accurate bending

Stirrup bending machines provide greater accuracy and precision in size and shape compared to manual labor, which is crucial for the strength of any structure. With manual labor, there is always a risk of human error, leading to inconsistencies in the bent rebars. Stirrup bending machines eliminate this risk, ensuring that each rebar is bent according to the specified dimensions and angles.

Consistency in bending

Uniformity in stirrup size and shape is essential for structural strength, achievable through the use of stirrup bending machines. By automating the bending process, you can ensure that every rebar is consistent in size and shape, contributing to the overall stability and durability of the structure being built.

Reduced labor costs

While the initial cost of purchasing a stirrup bending machine can be high, it saves money in the long run by reducing labor expenses. With the machine doing the work of multiple laborers, you can cut down on the number of workers needed on-site, thereby lowering labor costs.

Improved worker safety

Minimizing risks associated with manual bending helps to ensure worker safety on construction sites. Manual bending of rebars can lead to injuries and accidents while using a stirrup bending machine minimizes these risks. In addition, with fewer workers needed on-site, the chances of workplace accidents are further reduced.

4 Types Available

There are several types of rebar stirrup bending machines, each with unique functions and capabilities. This article discusses the top four:

Manual type

Simple and affordable, manual machines are easy to operate but best suited for projects with small production output.

Although they require more physical effort from the operator, manual rebar stirrup bending machines are a cost-effective solution for small construction projects with limited budgets.

Electric type

Similar to manual machines but electrically powered, electric machines offer greater precision and accuracy, suitable for small to medium-sized projects.

They are more efficient than manual machines, allowing you to complete projects faster and more accurately. Electric rebar stirrup bending machines are also more user-friendly, making them a popular choice among construction professionals.

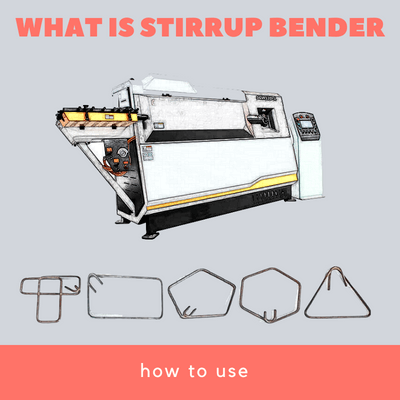

Hydraulic type

Powered by hydraulics, these machines are versatile and capable of bending rebars and steel rods into any shape and size with high accuracy, ideal for large-scale projects.

Hydraulic rebar stirrup bending machines are more powerful than their manual and electric counterparts and offer better performance for heavy-duty construction work. They are suitable for large-scale projects with high production output.

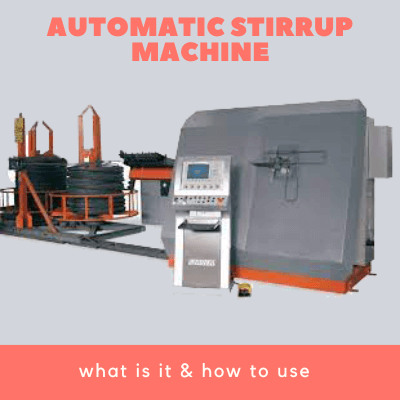

CNC type

CNC (Computer Numerical Control) machines are computer-controlled, offering maximum accuracy and precision in stirrup bending, even for complex shapes.

These advanced machines are ideal for high-volume production and large-scale construction projects, ensuring consistent quality and minimizing errors. CNC rebar stirrup bending machines provide an unparalleled level of control, allowing for greater customization and adaptability to various project requirements

Factors to Consider When Choosing

To make an informed decision when purchasing a rebar stirrup bending machine, consider the following factors:

Capacity of the machine

The machine’s capacity determines the maximum thickness of rebar it can bend, influencing the size of the projects it can handle. Be sure to choose a machine with a capacity that matches the requirements of your construction projects.

Type of machine

The type of machine you choose should be based on the size and scope of your projects. For smaller projects, a manual or electric machine may suffice, while larger projects may require the power and versatility of a hydraulic or CNC machine.

Durability and reliability

Choose a machine that is built to withstand the wear and tear of heavy construction work. Investing in a durable and reliable machine will ensure that it lasts longer and performs optimally, ultimately saving you money in the long run.

Ease of use and maintenance

Select a machine that is easy to operate and maintain, ensuring that it stays in optimal condition throughout its lifespan. Machines with easily accessible spare parts will be more convenient to service and repair, minimizing downtime and keeping your projects on schedule.

Cost of the machine

Consider your budget when choosing a rebar stirrup bending machine, balancing the initial investment against long-term savings from reduced labor costs and increased efficiency.

How to Use

To operate a rebar stirrup bending machine safely and effectively, follow these steps:

Preparation

Prepare the machine and safety gear before operation, ensuring that all components are in good working order and all safety protocols are in place.

Setting up the machine

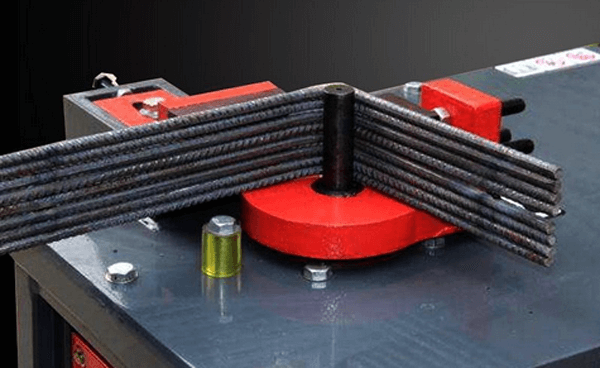

Position the pins and rollers correctly to achieve the required angle for the desired stirrup shape.

Loading the rebar

Load the rebars into the bending machine, aligning them properly with the rollers and pins for accurate bending. Secure the rebar in place before starting the machine.

Bending the rebar

Start the machine, allowing the pins and rollers to engage the rebar and bend it into the desired shape.

Unloading the rebar

After bending the bars, unload them from the machine, set them aside, and switch off the machine.

Safety Measures for Using

Adhering to safety measures is crucial when operating machinery like rebar stirrup bending machines. Follow these guidelines to ensure a safe working environment:

Personal protective equipment (PPE)

Wear appropriate PPE, including gloves, safety glasses, boots, and hard hats, to protect against injuries and accidents while operating the machine.

Machine-specific safety measures

Each machine comes with a specific instruction manual containing safety guidelines. Follow these instructions carefully to minimize the risk of accidents or injuries.

Emergency procedures

Turn off the machine when not in use, clear any debris, and follow other emergency procedures as recommended by the manufacturer.

Maintenance and Troubleshooting

Regular maintenance is crucial for the longevity and efficiency of your rebar stirrup bending machine. Follow these tips to keep your machine in optimal condition:

Regular maintenance tasks

Perform regular maintenance tasks, such as lubricating moving parts, cleaning the machine, and checking for worn or damaged components. Replace any damaged parts promptly to prevent further damage and ensure the machine’s efficiency.

Troubleshooting common problems

Familiarize yourself with common issues that may arise during the operation of the rebar stirrup bending machine, such as irregular bending angles or excessive noise. Consult the machine’s instruction manual for guidance on troubleshooting these issues and seeking professional assistance when necessary.

When to call in a professional

If you notice any technical issue, it is best to call a professional or contact the manufacturer.

Conclusion

Rebar stirrup bending machines offer numerous benefits for construction projects, including increased efficiency, accuracy, and reduced labor costs. By understanding the different types of machines available, their features, and how to choose the right one for your needs, you can maximize the advantages they provide.

Additionally, adhering to safety measures, performing regular maintenance, and keeping an eye on future trends will ensure that you stay ahead in the industry and provide the best possible service to your clients. By incorporating rebar stirrup bending machines into your construction projects, you can significantly improve the quality, efficiency, and overall success of your work.

Leave A Comment