Automatic Stirrup Machine: What Is It & How To Use

Stirrups are one of those construction elements that may seem small but are very important. Stirrups are essential as they keep the main reinforcement together closely and tightly.

The stirrups’ purpose is to provide shear resistance, especially on critical points of a structural reinforced concrete that can prevent it to buckle or crack open. Stirrups and ties give stability to your reinforced concrete element which lessens the growth of the cracks.

Unlike main rebar, which are cut straight with usually a hook in the other side, rebar are formed in different styles depending on the shape and legs. The most usual stirrup shapes are rectangular, square, diamond, circular and hoop.

While stirrups legs can be single, double, four or six legged. Wherein these shapes can be of both depending on the complexity of the structure. Another is that compared with the main rebar which are in a length of the beam, stirrups are being placed in different spacing, closer in the support and farther towards the middle.

These means that in a beam there can be multiple number of stirrups.

Because of the number of stirrups in a beam, the production of these stirrups should be fast and adequate to not have a negative time impact. A negative time impact will reflect to the cost as well as when the project will end.

Because of these reasons, it is advisable, especially on large project, to use an automatic stirrup machine.

Contents

What Is Automatic Stirrup Machine

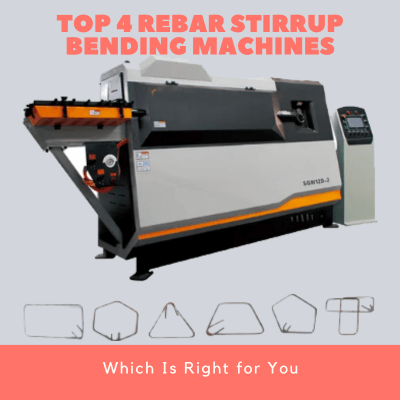

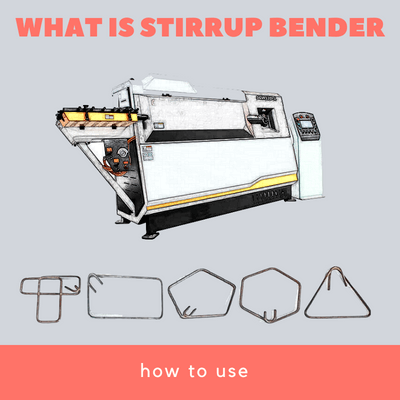

An automatic Stirrup Bending Machine is an advance equipment that offers more than just bending the rebar to become a stirrup or tie.

This automatic bending machine can also straighten and cutting of steel bar as it is being bent to its desired bent anchorage. The automatic stirrup machine can produce many and accurately made stirrups in a short span of time which will be good in the project.

A swift production results to an advancement of the project completion. Because you will be feeding a roll of rebar, wastage will also be less on the construction site which will be a positive cost impact.

How Does The Automatic Stirrup Machine Works

The automatic stirrup machine works using the control. These control will be responsible with the rebar shape, hook/bend angle, number of stirrups and cutting length.

The rebar, after being fed, will pass through a series of rollers which primary purpose is to straighten the rebar before forming it into a rebar. When it is done passing through the rebar straightener, it will be then fed to the stirrup machine where in it will be bent on specific length, formed depending on the desired stirrup shape and be cut once done.

These process will be repeated until the required number of stirrups are done being made.

How To Operate Or Use The Automatic Stirrup Machine

There are three steps that are needed to be followed for you to avoid malfunctioning of the machine during the usage and to avoid dissatisfaction of the finished stirrups. These are the feeding, the control and the execution.

Feeding

Since in using this automatic stirrup machine, you will be using a large roll of rebar. These roll of rebar are hard to form since they are in spiral. This is the purpose of the straightening machine.

First, loosen the rollers found first which will hold the rebar. After loosening the rollers, feed the rebar to these rollers. Once you have fed the rebar to the first rollers, tighten the rollers so that it will not be loose or sway during the execution.

Loosen the series of rollers responsible for straightening the rebar to allow the fed rebar to pass through. Using the controls, slowly allow the rebar to pass through the straightening rollers.

Once it passed through the last series of rollers, pause the feeding of the rebar. Sufficiently tighten the straightening rollers according to your desired tightness.

Be mindful that it should not be too tight that the rebar will be stuck and not push through or too loose that the rebar will not be straightened as it passes through that part of the machine.

Once you have adjusted the straightening rollers in your liking and as required, slowly press the control to continue the rebar to pass through until it reaches to the feeder where the rebar will be formed and cut into a stirrup.

Controls

Because of the advancement of the technology, the machine provides a series of template for different common stirrup shapes like rectangle, square, triangle or circular and even the complicated one where one stirrups can be a combination of many stirrups which are usually found on beams with many main rebar. Aside from the template, you can customized the shape of the stirrup.

After choosing your stirrup shape, you may customized the dimension of the length & width, as well as the interior angle of the stirrup and the hook angle and length.

After doing so, input the number of stirrups that needs to be made and cut.

Execution

After doing the necessary changes or modification on the controls, press the start and press the automatic. When it automatically fed, press the start again to continue the process. Wait and see as the machine straighten, form and cut the rebar into your desired stirrup shape.

After completing the number of stirrups to be made and cut, the machine will automatically stop the operation.

Simply, loosen the necessary rollers from the straightening and the feeding to remove the rebar that was fed to the automatic rebar machine.

Conclusion

Time is essential in construction, especially on large project which involve massive budget. Investing in a machine, just like the automatic stirrup machine, will be a positive impact in the construction phase as it provides an increase in productivity, lesser waste, precise, more accurate stirrup shape and lesser labor cost. This may even provide an advance in your construction schedule.

Automatic stirrup machine is an investment wherein it doesn’t just provide the shaping of the rebar into a stirrup but allows it to be straighten first to achieve the best stirrup shape and it can also automatically cut after being formed.

Leave A Comment