The Ultimate Guide to Robin Tamping Rammer: All You Need to Know

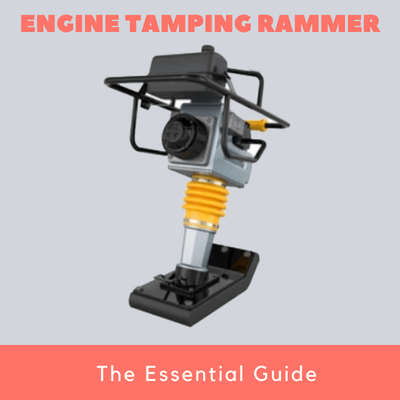

Robin tamping rammers are equipment used for compacting soil by tapping and are especially useful in tight locations where other machines cannot be utilized.

Tamping rammers powder hefty pieces of soil particles and improve soil dry density. To compress the soil surface, a force of 2-3 tonnes is used at a frequency of 600-700 blows per minute. The compacting force is best suited for sticky and cohesive soils. They are very useful for compacting ditches and other limited locations.

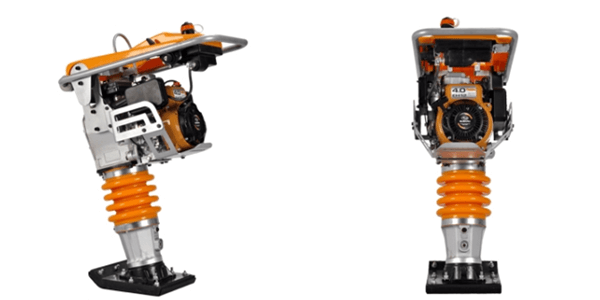

Jumping jacks are another name for taming rammers. The term comes from the functioning concept and design that is built at an angle to allow for a leaping action. A torque-producing engine by Robin, a gear, a spring cylinder, and a plate shoe are the main functioning components of the jumping jack.

The Robin engine produces torque, which is delivered to the crank gear in the form of a reciprocating motion. The motion is then transferred to the rammer’s shoe through a spring wrapped in a cylinder. As a result, a vibrating motion is created in the machine’s shoe.

Contents

Features of a Robin Tamping Rammer

The Tamping Rammers are well-balanced and ergonomically built. Tamping rammers are flexible, small, and attractive, and are powered by the dependable Robin engine to offer optimum comfort and productivity.

Engine Power

Horsepower is the amount of power produced by an engine. It is computed as the force required to move 550 pounds one foot in one second or 33,000 pounds one foot in one minute. The power is measured by the time it takes to complete the task.

Tamping rammer with Robin engines can offer 4HP(EH12,) and 5 HP(EY20, 183cc).

Tamping Force

Tamping force is the amount of force delivered by the rammer to compact the soil. Usually, a large number of forces are required for cohesive soils. A Robin tamping rammer can deliver 12 kN force with a frequency of 600-700 t/min.

Foot Size

Usually larger the foot size more would be the area that would be compacted. However, rammers with larger foot areas might not be accessible to the tight area. A Robin Tamping rammer has usually a foot area of 300 x 300 mm

Weight

With a Robin engine, a tamping rammer can weigh up to 80 kg. An engine is usually not the heaviest part of the rammer. Instead, it is its shoe plate. The heavier is the shoe plate, more would be the force delivered to the soil.

Benefits of Using a Robin Tamping Rammer

Here are a few reasons why rammers are awesome:

Efficient Compaction

They have the ability to compress more deeply than vibrating plate compactors. They can compress a wider range of materials than vibrating plate compactors.

Durable Design

Rammers using robin engines are long-lasting. The four-cycle engines are lubricated through the crankcase rather than the gasoline, which prevents oil from burning in the cylinders. It also helps to decrease buildup and gumming difficulties.

The engine’s multi-stage air filtration system greatly reduces dust in the intake air. The filter is simple to reach and clean, with little risk of dust entering the system. Rammers are also equipped with heavy-duty PVC protective cover protectors to safeguard electrical components.

Easy to Use

Robin Rammers’ vertical form makes them perfect for hard-to-reach areas where compactors may struggle. They are very maneuverable and can cover a lot of distance rapidly due to their small footprints and strong punch. The machines are compact and thin, with a minimal footprint. Because of their design, they are easy to manage.

Versatile Applications

Robin tamping rammers are intended for compacting cohesive soils like clay and silt in tiny repair tasks and in limited locations like trenches or house sites, but they may also be used on sand and gravel.

Considerations when Purchasing a Robin Tamping Rammer

Quality

The fuel system of the rammer you purchase is critical to its lifespan. Check that the rammer’s engine has a diaphragm carburetor that can consistently provide fuel to the rammer despite hits and vibration. Using an engine with a bull float carburetor is not an optimum setup. Bull Float carburetors will clog, resulting in occasional rammer leaping.

A rammer’s bellows are an essential component. This component allows a rammer and internal spring to leap at about 700 beats per minute. Below the gearbox and above the rammer shoe are bellows made of ribbed polyurethane. Not all bellows are made equal. There are bellows that are made of high-quality polyurethane and are tooled using precise equipment at ideal temperatures.

Then there are recycled bellows, which have a lifespan of only 20 hours. Despite its simplicity, a well-crafted bellow will have a powerful spring after millions of leaps. If a rammer is bouncing at 700 beats per minute, the durability and spring will wear down soon if the part is of poor quality.

Price

Price is always the consideration. However, you should never compromise for lower prices.

Warranty

Manufacturers usually offer a warranty for their equipment. Go for the equipment with the longest warranty and the best customer support. Usually, rammers with Robin engines come with a warranty of 1 year at least.

Ease of Maintenance

Parts availability is critical for any device you buy. To keep a job site functioning well, the necessary equipment and components must be always available. Make sure the rammer you buy has components accessible from the manufacturer or retail outlet where you bought it. If your tamper breaks or becomes damaged, you may simply obtain the replacement components you require to get it back up and running.

Conclusion

Rammers powered by robin engines survive a long time. The four-cycle engines are lubricated via the crankcase rather than through the fuel, preventing oil from burning in the cylinders. The vertical shape of Robbin Rammers makes them ideal for hard-to-reach regions where compactors may struggle.

Because of their small footprints and powerful punch, they are extremely agile and can cover a great deal of ground quickly.

I have bought robin Tamping rammer around the end of October. I am impressed due to its performance but it does floods petrol

good

I have bought robin Tamping rammer around the end of October. I am impressed due to its performance but it does floods petrol

good