Concrete Power Float: 6 FAQs [When, Tolerance, Rain, Hardener…]

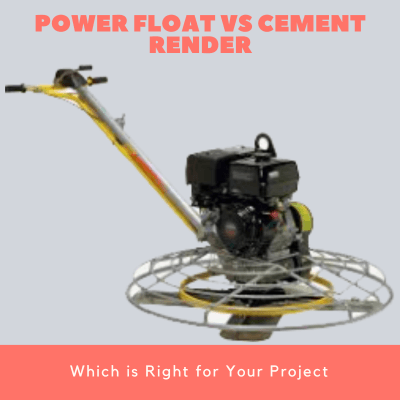

Concrete power float is used to produce dense, smooth, and leveled surface finishes to the cast in place concrete surfaces like a concrete slab.

It is a hand-operated machine that can reduce the time and material required for finishing in comparison to screed finishing. It is much quicker and requires less labor effort than hand finishing.

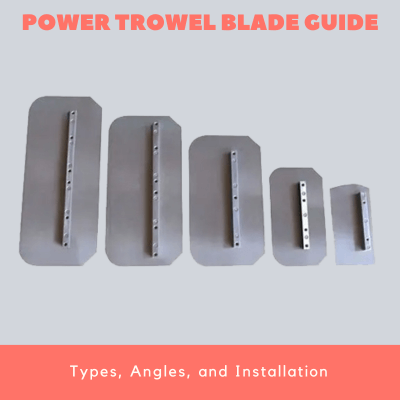

These machines are powered by electric motors or petrol engines, which are fixed on the top of a metal pan. The metal pan is fitted with blades. The blades can rotate up to 150 RPMs over the concrete surface to produce nicely finished hardened concrete.

In this article, we will discuss, when and how to use concrete power float and what is finishing tolerance we can achieve with it. A few special cases of power float use would also be discussed.

It should be kept in mind that concrete helicopter and power trowel are also the names used for concrete power float.

Contents

When to Power Float Concrete

Concrete must be left for some time to partially set before using the power float. It should be leveled and tamped before.

Different variables like air, humidity, and mixed design of the concrete, temperature, and many more affect the setting time of concrete.

How Long After Pouring The Concrete Can You Power Float It

A layman’s guide can be that when you walk on the set concrete, the marks left by your feet are not more than 3-4 mm deep. If they are deeper this means you should wait more time to achieve proper setting in the concrete.

If you start working on the concrete that is too wet and not properly set, the power float will tear the surface. This would be a negative effort.

On the other hand, if the concrete is too much dry then in this the use of the machine cannot be made too effectively. You may not be able to effectively trim high spots or fill the lower spots.

On average, concrete can take at least 20 minutes to get set. In some cases, it can take up to several hours to get dry. The following factors play a key role in defining the setting time of concrete.

- With an increase in the humidity, the setting time of concrete will also increase and vice versa.

- With an increase in the temperature, the setting time of concrete will decrease and vice versa.

- With an increase in the wind speed, the setting time of concrete will also increase and vice versa.

How to Power Float a Concrete Floor/Slab

The process of floating will usually start from one corner and finish at the other. The power float must be held at the waist height and then it is moved in the backward direction. The reason behind moving it in the backward direction is that you will also be able to remove your footprints in this manner. While doing so, the speed of the machine should be slow and consistent.

After floating the surface once, the angle of the blade is aligned to achieve the desired level of finish in the concrete. The angle of the blade should be around 5 to 10 degrees normally. However, they can also be increased in successive passes.

Power Float Finish Tolerance

The finishing quality of concrete can be gauged by different tolerances, which are defined in local building codes.

For example, in the USA following 4 classes of concrete finishing are defined by the American Concrete Institute (ACI). These classes are gauged by measure the vertical distance below the straight edge place on the concrete surface.

- Class A finish- 1/2 inches below a 10-foot straight edge.

- Class A-2 finish- 3/16 inches below a 10-foot straight edge.

- Class B finish- 1/4 inches below a 10-foot straight edge.

- Class C finish- 1/4 inches below a 2-foot straight edge.

Class C finish is the worst quality of finish as it includes the biggest heaps.

Similarly, in Australia, a different tolerance system exists. It is recommended there to check the quality of finish produced by the float by placing a 3m (10 foot) straight edge on the concrete surface.

If any high spots are detected, the concrete should be floated again and again until all the high spots disappear. The tolerance of any machine trowel depends on the shape of its blade fans. Usually, it is specified by the manufacturer.

In any case, as discussed earlier, you can improve the quality of finish by increasing the number of floats passes.

Power Floating Concrete in The Rain

If it rains when you are power floating. You should immediately stop and cover the concrete with some protecting material.

In case of very hard rain, it can almost wash away any unset concrete. Therefore, you should be very careful and protect the concrete.

After the rain has finished, you must first remove the covering and allow the concrete to properly as per guidelines given earlier. Doing anything in a bit of a hurry will destroy your concrete. Using a concrete power float on concrete which not properly set will do negative work and will destroy its finish.

In cases when it’s raining light like drizzling or a little short shower, you may continue to power trowel the concrete. But in this case, you would require more passes on the concrete surface.

Floor With Concrete Hardener

The concrete hardener is a non-metallic, pre-blended hardening material that is used to provide high strength, durable, and long-lasting wearing surface in any concrete surface.

Power float can also be used to finish such concrete surfaces.

However special instructions regarding the speed of the machine and the number of passed may have to be followed, which depend on the type of hardener being used in the concrete.

Conclusion

In this article, we discussed when to use power float and how it must be used. Several indications about the tolerances that can be achieved by a power float are discussed.

Lastly, some special cases like raining and concrete hardeners are also discussed and guidelines are provided on the use of concrete power float in such cases.

Leave A Comment