Power Float vs Cement Render: Which is Right for Your Project

Finishing a concrete structure is an important aspect of any construction project, as it can impact the appearance and durability of the final product. Among the various methods and materials used for finishing, power float and cement render are two popular options that offer different benefits depending on the specific needs of a project.

Power float involves using a machine to create a smooth and level surface, while cement render involves applying a layer of cement and sand mix to create a textured finish. Choosing the right technique for your construction project is essential to achieving the desired outcome and avoiding issues such as cracking, peeling, or flaking.

Brief overview of power float and cement render

When it comes to finishing concrete structures, power floating and cement rendering are two popular techniques used by construction professionals. Power floating involves using a power trowel to create a smooth and level surface, while cement rendering involves applying a layer of cement and sand mix to create a textured finish. These techniques offer different benefits and drawbacks depending on the specific needs of a project.

Importance of choosing the right technique for your construction project

Choosing the right technique for your construction project is crucial, as it can impact the final appearance, durability, and maintenance requirements of the structure. The wrong technique can lead to issues such as cracking, peeling, or flaking, and may require costly repairs or maintenance in the future. It’s essential to consider factors such as the location, intended use, and budget of the project when selecting the appropriate technique.

Contents

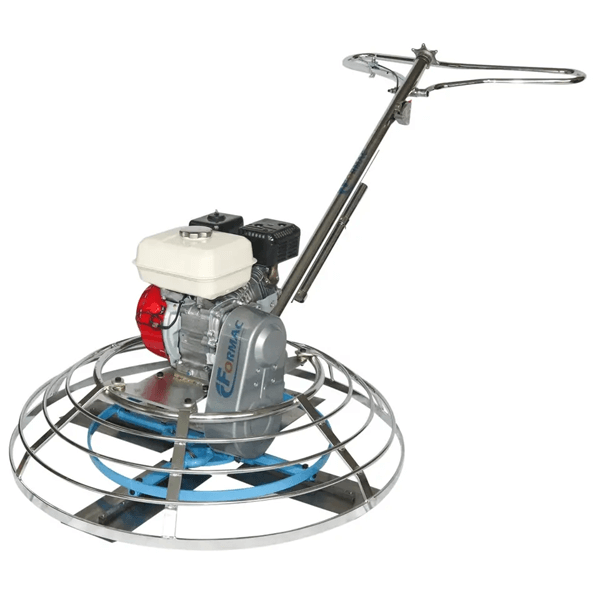

What is Power Float

Definition and how it works

- Power floating is a technique used to finish concrete surfaces, which involves using a power trowel machine to smooth and level the surface.

- The machine’s rotating blades apply pressure to the surface, which forces down aggregate and creates a dense, durable finish.

- The process involves several steps, including floating, troweling, and finishing, to achieve the desired smoothness and levelness.

Advantages and disadvantages of using power float

- One of the primary advantages of power floating is its ability to create a smooth, even surface that’s resistant to wear and tear.

- It requires less manual labor than other finishing methods, which can save time and money.

- However, power floating can be more expensive than other finishing methods, especially for smaller projects.

- It may not be suitable for all types of concrete surfaces, particularly those with intricate designs or patterns that require more detailed finishing work.

- Additionally, the use of a power trowel machine can be noisy and produce dust, which can be a concern in certain environments.

Best applications for power float

- Power floating is well-suited for large, flat surfaces such as floors, walls, and driveways.

- It’s a good choice for surfaces that will be subjected to heavy foot traffic, machinery, or other types of wear and tear.

- However, it may not be ideal for surfaces with intricate designs or patterns, as the machine’s blades can’t reach tight corners or edges.

What is Cement Render

Definition and how it works

Cement render is a technique used to finish concrete surfaces by applying a layer of cement and sand mix to create a textured finish. The mix is usually applied with a trowel or hawk and then smoothed or textured, depending on the desired finish.

Advantages and disadvantages of using cement render

- One of the primary advantages of cement render is its versatility in terms of finish options. It can create a variety of textures, from smooth to rough, depending on the tools and techniques used.

- It’s also relatively inexpensive compared to other finishing methods, making it a good choice for budget-conscious projects.

- However, cement render can be more time-consuming than other finishing methods and requires more manual labor, which can be a drawback for larger projects.

- It’s also prone to cracking and peeling if not applied correctly, which can compromise the durability of the finished surface.

Best applications for cement render

- Cement render is a good choice for exterior walls and facades, as it can provide a durable and attractive finish that’s resistant to weathering and moisture.

- It can also be used for interior walls, particularly in areas where a textured or decorative finish is desired, such as accent walls or fireplace surrounds.

- However, it may not be suitable for large, flat surfaces such as floors or driveways, as the texture can make them difficult to clean or maintain.

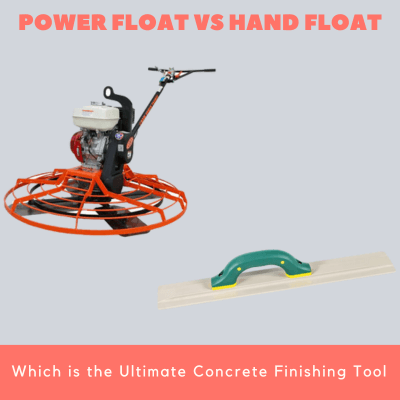

Comparison of Power Float and Cement Render

Differences in application and outcome

- Power floating is primarily used to create a smooth, level finish on large, flat surfaces such as floors and walls.

- Cement render, on the other hand, is typically used to create a textured finish on exterior or interior walls.

- The tools and techniques used in each method are different, with power floating using a power trowel machine and cement render using a trowel or hawk.

Cost comparison

- The cost of each method can vary depending on factors such as the size of the project, the quality of materials used, and the labor costs in the area.

- Power floating tends to be more expensive due to the use of specialized equipment and the level of skill required to operate it.

- Cement render, on the other hand, is relatively inexpensive in terms of materials but may require more manual labor, which can increase labor costs.

Durability and maintenance considerations

- Both power floating and cement render can provide durable finishes, but the specific durability will depend on factors such as the quality of materials used and the level of skill of the applicator.

- Power floating can provide a smooth, even surface that’s resistant to wear and tear, making it a good choice for high-traffic areas such as floors.

- Cement render can provide a textured finish that’s resistant to weathering and moisture, making it a good choice for exterior walls.

- Maintenance considerations will also vary depending on the specific application, with power floating requiring periodic resealing or polishing to maintain its finish, while cement render may require periodic repainting or touch-ups to maintain its appearance.

Which is Right for Your Project

Factors to consider when choosing between power float and cement render

- The specific goals and requirements of your project, such as the desired finish, the location of the project, and the level of durability required.

- The overall budget for the project, including material and labor costs.

- The availability of skilled contractors in your area who are familiar with the specific technique you choose.

Questions to ask your contractor

- Ask about their experience and expertise with both power floating and cement rendering.

- Ask for examples of similar projects they have completed and for references from past clients.

- Ask about their process for selecting the best technique for your project, and how they will ensure that the finished product meets your requirements.

Real-world examples and case studies

- The Beijing Daxing International Airport Terminal 2, which opened in 2019, features large concrete floors that were finished using power float. The airport is one of the largest in the world and the use of Power float helped to create a smooth, durable surface that can withstand heavy foot traffic.

- The Shanghai Tower, completed in 2015, is a 632-meter skyscraper that features a unique twisted design. The exterior of the building was finished using cement render to create a clean, modern look that is resistant to weathering.

- The Hong Kong-Zhuhai-Macau Bridge, which opened in 2018, features large concrete surfaces that were finished using power float. The bridge is the world’s longest sea-crossing bridge and the use of power float helped to create a smooth, level surface that is resistant to wear and tear.

- The Guangzhou Opera House, completed in 2010, is a stunning piece of architecture that features a flowing, organic design. The exterior of the building was finished using cement render to create a smooth, clean surface that is resistant to water and weathering.

Conclusions

In conclusion, both power floating and cement rendering are effective techniques for achieving a smooth, durable, and visually appealing finish for your construction project. However, choosing the right technique for your specific project requires careful consideration of several factors, such as the desired finish, location, budget, and availability of skilled contractors.

Power floating is best suited for large, flat surfaces such as warehouse floors, while cement rendering is ideal for creating a textured or patterned finish on vertical surfaces such as walls. Both techniques have their advantages and disadvantages in terms of cost, durability, and maintenance.

It certainly helped when you informed us that cement render is great for exterior walls and facades since they’re durable enough to withstand weathering and moisture. I’m getting my grandma’s house remodeled this summer, so I need to get the exterior walls rendered as well to ensure the house stays sturdy. I’ll keep this in mind while I look for cement rendering services to hire for help soon with our remodeling project.

Hi Elina Brooks, thank you for your comments

Very thankful for this wonderful article, it seem like it will really help with what I need to get done. Thank you very much for the post!

Hi Ashley, glad to hear it is helpful