How To Use Float Pan & Adjust Blades [Power Trowel]

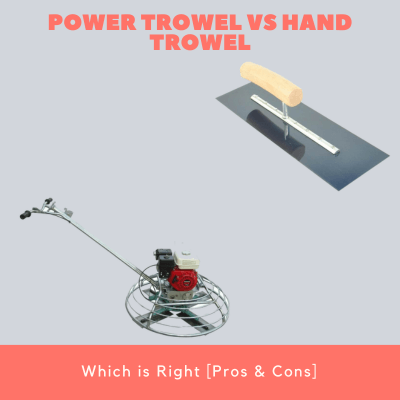

Concrete finishing is one of the most important step after the concrete pouring and one of the most used equipment is the power trowel. Power trowel is used for smoothening and polishing during the curing of the concrete pouring but also to create a more leveled and compacted finish of the concrete slab to get the desirable and professional finish.

Power trowel can be of two types, the walk behind and ride on power trowel. The walk behind power trowel is much more applicable for smaller and tighter areas while ride on power trowel is for wider area. The walk behind power trowel is operated by holding and manuevering while ride on power trowel is operated by a riding operating and using controls to manuever.

In order to effectively polish the fresh concrete, you must be aware of the different attachment to the power trowel. The most basic attachment for power trowel are the float pan and the blades.

concrete trowel machine start from $150

Contents

How To Use Float Pan

Float pans, also known as float disk, are circular attachment to the power trowel bottom which will be clipped on the trowel blades. Floats are used for the initial step of polishing of the fresh concrete. These disk are widely because it can be a good tool for the transition from wet concrete to dry concrete while floating, it can also give a flatter appearance of the floor and it can increase the productivity during floating.

So how do you attach the float pan? Float pans have a clip angles for the purposes of attaching it to the blades. For the attachment, lay the pan flat to a surface, turn on the power trowel and use a slow rotation for the blades to engage with the float pans. Once the pans are clipped to the blades, it can now be use for floating.

How to use the float pans? Float pan bottoms can be of two types, the flat and the slightly curved. The slighty curved float pan clearance from the slab is very little, an inch to the edges of the float pan and the inside curve can vary from 3 to 4 inches.During the floating, always start the floating perpendicular to the screeding direction and manuever the trowel perpendicular to the previous direction. Floating, considering both the direction, creates a more flat and leveled finish compared to focusing on one direction and make the changes in the level after the floating which takes time.

Another would be, consider the speed and the number of passes during the floating. Technically, the number of passes depends on the concrete slump, the admixtures, the weather as well as the desired finish of the slab. Usually, it takes 4 or more passes to get the desired finish. While with the power trowel speed for floating, always consider using the minimum speed during the start so you can control the direction and movement of the power trowel. Directly using the maximum speed of the power trowel may cause to damage the fresh concrete which takes more time and more works to be done.

The float pan sizes varies and are sized to fit the power trowel. The diameter can range from 24 to 48 inches and have a gauge from 10 to 12.

For the beginners, it is best to use the flat float pan as using the slightly curved float pan can create a wavy finish if used unsupervised and with little to no experience. Once, you have adjusted and know how to control the power trowel, slightly curved float pan can be used.

Float pans are important because it lessens the bumps and voids on the finished concrete slab, to compact the concrete and aggregates and adjust the imperfections of the finished slab.

How To Adjust Blades

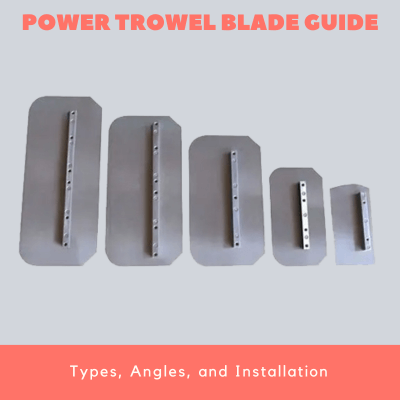

After the floating, you may now proceed using the power trowel using blades. These blades can be of two type: the combination blade and the finishing blade.

The combination blades are a hybrid from floating and finishing blade. The size of the combination blade is wider than the floating blade but are smaller than the finishing blade. Since this blade is a combination of both, it is designed to do both but are not as best as with the blades that are intended for the finishing job. The combination blade can be use during fresh concrete for floating and finishing at the same time. These blades are to increase the productivity in a short time while getting your desired finish.

The finishing blades are for the purpose of finishing the concrete slab finish. Since the purpose of the these blades are for the finishing, the surface area targeted are more concentrated and in a higher speed. The finishing blades are for sealing off of the concrete finish ready for its final curing.

These blades, the combination and finishing blades, can be made from stainless steel and plastic.

concrete finishing machine start from $150

Conclusion

Another contributor aside from the attachment on the power trowel is the right time to begin the floating transitioning finishing. The first pass should be confirmed by pressing the fresh concrete and that its depth of mark is from 1/8” to 1/4” which is the best time of using the power trowel. Avoid starting the floating when bleedwater is present as it can cause scaling and dusting of the finished concrete slab.

As these blades and pans can be made from stainless steel or other metal, proper maintenance and storage should also be considered with the quality of the materials. Always have the initiative to check the blades and pans as it can be prone to wearing off. These defects can affect the quality of the finished slab wherein the rust can stick on the wet concrete which can cure together with your slab. When the pans and blades have signs of rust, have inconsistency on the bottom, are wobble and have dents, it is best to replace the worn off material and invest in a high quality material of float pans, combination blades or finishing blades.

Leave A Comment