When to Power Trowel Concrete: The Guide to Perfect Time

Power trowelling is a critical step in the concrete finishing process, aimed at achieving a smooth and durable surface. However, knowing the right time to start power trowelling is essential to ensure optimal results.

This post will provide you with valuable insights on when to initiate power trowelling, considering factors such as concrete curing time, moisture content, strength, and ambient conditions.

By understanding the ideal timing for power trowelling, you can enhance the overall quality and longevity of your concrete projects, resulting in a superior finish.

A. What Power trowelling is:

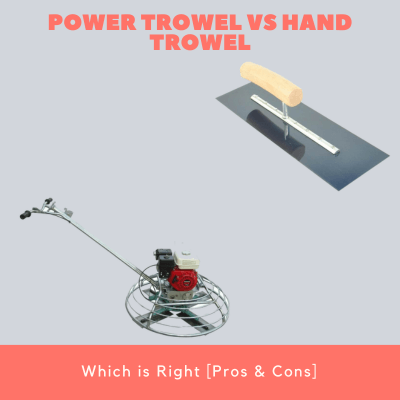

- Power trowelling is a method used to smooth and finish concrete surfaces using a power-driven machine equipped with rotating blades or pans.

- It is a crucial step in concrete construction to achieve a flat, smooth, and durable finish.

B. Importance of knowing the right time to start:

- The timing of power trowelling plays a vital role in achieving desired concrete surface characteristics.

- Starting power trowelling at the appropriate time ensures optimal concrete workability, strength, and surface finish.

- Timing errors can lead to poor surface quality, premature wear of trowel blades, or even concrete damage.

Contents

Factors to Consider

A. Concrete curing time

- Concept of concrete curing:

- Concrete curing is the process in which water is added to the concrete mix, allowing it to hydrate and harden over time.

- During curing, the chemical reaction between water and cement takes place, forming strong bonds and increasing the strength and durability of the concrete.

- Proper curing is essential to achieve the desired properties of the concrete, including strength, durability, and resistance to cracking.

- General curing time for different types of concrete:

- The curing time for concrete can vary depending on factors such as the type of cement used, ambient temperature, humidity, and mix design.

- In general, it is recommended to wait at least 24 to 48 hours before power trowelling the concrete.

B. Concrete surface moisture content

- Importance of moisture content:

- Moisture content in the concrete surface affects the trowelling process and the final finish.

- Excessive moisture can lead to weak concrete, increased shrinkage, and reduced strength.

- Insufficient moisture can result in a rough and uneven surface.

- Testing moisture content:

- Moisture meters or plastic sheet tests can be used to assess the moisture content of the concrete surface.

- These tests help determine if the concrete is dry enough for power trowelling.

- Ideal moisture content ranges for power trowelling:

- Generally, the moisture content of the concrete surface should be below 6% for power trowelling.

- However, specific moisture content requirements may vary based on project specifications and concrete mix design.

C. Concrete strength

- Relationship between concrete strength and power trowelling:

- Concrete strength is a critical factor in determining the appropriate time for power trowelling.

- Trowelling too early can damage the concrete surface, while trowelling too late can result in inadequate finishing.

- Testing concrete strength:

- Concrete strength can be tested using compressive strength tests, typically performed by certified laboratories.

- These tests provide an indication of the concrete’s strength and help determine the optimal time for power trowelling.

- Guidelines for minimum strength requirements:

- It is generally recommended to wait until the concrete reaches a minimum strength of 1500 to 2000 psi (pounds per square inch) before power trowelling.

- However, specific minimum strength requirements may vary based on project specifications and concrete mix design.

D. Ambient conditions

- Impact of temperature and humidity on power trowelling:

- Temperature and humidity can affect the curing process and the performance of the power trowel.

- Higher temperatures can accelerate the curing process, requiring earlier power trowelling.

- High humidity can slow down the curing process and extend the time required for power trowelling.

- Ideal ambient conditions for power trowelling:

- The ideal temperature range for power trowelling is typically between 50°F and 90°F (10°C and 32°C).

- Humidity levels should be moderate, avoiding excessively dry or humid conditions.

- It is important to consider the specific requirements of the concrete mix and project specifications when determining the ideal ambient conditions for power trowelling.

Recommended Timing for Power Trowelling

A. Guidelines based on concrete curing time:

- Follow the recommended curing time provided by the concrete supplier or engineer.

- Generally, wait at least 24 to 48 hours before power trowelling the concrete.

- However, specific curing times may vary depending on factors such as the type of cement used, ambient conditions, and mix design.

B. Guidelines based on moisture content:

- Ensure that the moisture content of the concrete surface is below 6% before power trowelling.

- Conduct moisture tests using appropriate methods, such as moisture meters or plastic sheet tests.

- Avoid power trowelling if the concrete surface is excessively wet or has not dried sufficiently.

C. Guidelines based on concrete strength:

- Wait until the concrete reaches a minimum strength of 1500 to 2000 psi (pounds per square inch) before power trowelling.

- Perform compressive strength tests to determine the concrete’s strength.

- Adhere to the specific minimum strength requirements specified by the project specifications and concrete mix design.

D. Guidelines based on ambient conditions:

- Power trowelling is typically performed within the temperature range of 50°F to 90°F (10°C to 32°C).

- Ensure moderate humidity levels, avoiding excessively dry or humid conditions.

- Consider the specific requirements of the concrete mix and project specifications to determine the optimal ambient conditions for power trowelling.

Conclusions

In conclusion, the timing of power trowelling plays a vital role in achieving a perfect concrete finish. Considering factors such as concrete curing time, moisture content, strength, and ambient conditions is crucial for determining the right time to start power trowelling.

By adhering to these guidelines and seeking professional advice when needed, you can ensure optimal results and enhance the overall quality of your concrete projects. Proper timing will contribute to the longevity, durability, and aesthetic appeal of the concrete surface, making it a worthwhile investment in your construction endeavors.

Leave A Comment