Riding a Power Trowel: Step-by-Step [Safely and Efficiently]

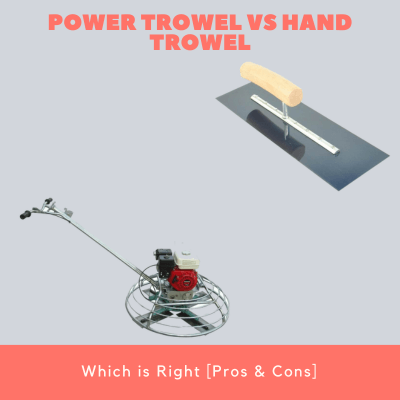

A power trowel is a versatile and essential tool used in the construction industry for achieving smooth and polished concrete surfaces. This compact machine, equipped with rotating blades, efficiently levels and finishes concrete slabs, making it a preferred choice for many concrete contractors.

Properly riding a power trowel requires knowledge, skill, and attention to safety, as it plays a crucial role in determining the quality of the final concrete finish.

In this post, we will provide step-by-step instructions on how to ride a power trowel safely and efficiently, ensuring optimal results for your concrete projects.

What a power trowel is

A power trowel is a construction machine used to create a smooth and level surface on concrete slabs. It consists of rotating blades that flatten and polish the concrete, making it suitable for various applications, including industrial floors, driveways, and sidewalks.

Instructions on riding a power trowel

The purpose of this post is to provide step-by-step instructions on how to ride a power trowel safely and efficiently. By understanding the proper techniques and safety measures, operators can achieve optimal results in concrete finishing while minimizing the risk of accidents and injuries.

Contents

Preparing for Operation

Safety Considerations

- Protective Gear: Before operating a power trowel, ensure you are wearing the appropriate protective gear, including a hard hat, safety goggles, hearing protection, and sturdy footwear. This gear helps safeguard against potential hazards on the job site.

- Familiarizing yourself with the Operator’s Manual: Review the operator’s manual provided by the manufacturer to understand the specific controls, safety features, and maintenance requirements of the power trowel. Proper knowledge of the machine’s functions is essential for safe operation.

- Clearing the Work Area: Before starting the power trowel, remove any debris, tools, or obstacles from the work area to prevent accidents and ensure a smooth and uninterrupted troweling process. Additionally, inspect the concrete surface for any potential hazards or irregularities that may affect the troweling process.

Mounting the Power Trowel

A. Checking the Power Trowel’s Condition

Before mounting the power trowel, perform a thorough inspection of the machine to ensure it is in proper working condition. Check for any signs of damage, loose parts, or malfunctioning components that may affect its performance or safety during operation.

B. Positioning the Power Trowel

- Leveling the Machine: Ensure that the power trowel is placed on a level surface before starting. An uneven surface can lead to unstable operation and affect the quality of the concrete finish.

- Ensuring Proper Clearance: Position the power trowel in a way that allows sufficient clearance around the work area. Avoid tight or confined spaces that may hinder maneuverability and potentially cause accidents. Additionally, ensure there is enough space for safe and smooth movement during the troweling process.

Starting the Power Trowel

A. Checking the Fuel and Oil Levels

Before starting the power trowel, check the fuel and oil levels to ensure they are sufficient for the operation. Running out of fuel or oil during troweling can lead to interruptions and potential damage to the machine.

B. Priming the Engine (if necessary)

If the power trowel has a manual primer bulb, use it to prime the engine by pumping the bulb until fuel fills the lines. This helps facilitate the engine’s startup process, especially after prolonged storage.

C. Starting the Engine

Turn the ignition switch or pull the starter cord (depending on the power trowel’s model) to start the engine. Follow the manufacturer’s instructions for proper starting procedures to avoid any issues.

D. Allowing the Engine to Warm Up

Once the engine starts, allow it to run at low throttle for a few moments to warm up. This ensures the engine reaches the optimal operating temperature and performs efficiently during troweling

Operating the Power Trowel

A. Understanding the Controls and Levers

Familiarize yourself with the various controls and levers of the power trowel. These may include throttle controls, blade pitch adjustment, and steering levers. Understanding their functions is essential for safe and efficient operation.

B. Maintaining a Proper Stance

Stand firmly and maintain a stable stance while operating the power trowel. Distribute your weight evenly and keep a balanced posture to ensure better control and stability during troweling.

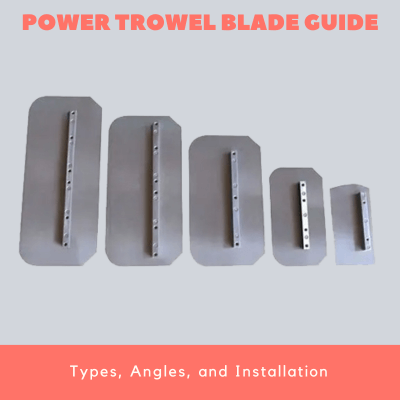

C. Starting the Blades and Adjusting the Pitch

Engage the power trowel’s blades by using the appropriate control. Adjust the blade pitch to the desired angle, which affects the troweling depth and efficiency. Ensure that the pitch is set correctly before troweling.

D. Moving the Power Trowel Smoothly

Gradually increase the throttle to move the power trowel smoothly. Avoid sudden jerks or rapid acceleration, as they may lead to uneven troweling and potential safety hazards.

E. Navigating Around Obstacles

When encountering obstacles such as construction joints or formwork edges, use caution and maneuver the power trowel carefully. Slow down and approach obstacles at an angle to minimize the risk of blade catches or uneven finishes.

F. Controlling the Speed and Direction

Use the steering levers to control the direction of the power trowel. Practice maneuvering the machine at a consistent speed to achieve a uniform concrete finish. Adjust the speed as needed based on the project’s requirements and surface conditions.

Finishing the Operation

A. Gradually Reducing the Blade Pitch

- As you approach the end of the troweling process, gradually reduce the blade pitch to a flatter angle. This helps in achieving a smoother and more refined finish on the concrete surface.

B. Turning off the Power Trowel

- When you have completed the troweling operation, gently lower the blades to the ground and turn off the engine using the appropriate controls. Ensure that the power trowel comes to a complete stop before dismounting.

C. Cleaning and Maintaining the Power Trowel

- Removing Debris: Clear any concrete residue, dirt, or debris from the power trowel’s blades and body. A clean machine ensures better performance and extends its lifespan.

- Checking for Damages: Inspect the power trowel for any signs of damage or wear. Look for cracks, bent blades, or loose parts. Address any issues promptly to avoid safety risks and operational inefficiencies.

- Lubricating Moving Parts: Regularly lubricate the power trowel’s moving parts as per the manufacturer’s recommendations. Proper lubrication reduces friction, prevents premature wear, and enhances the machine’s longevity.

Conclusions

In conclusion, riding a power trowel is a skill that requires knowledge, practice, and adherence to safety guidelines. This step-by-step guide has provided valuable instructions for efficiently and safely operating a power trowel during concrete finishing.

Remember to prioritize safety by wearing appropriate protective gear and maintaining a clear work area. By following the outlined procedures, you can confidently handle a power trowel and achieve smooth, professional concrete surfaces.

Continuous learning and practice will further enhance your skills, making you a proficient operator in no time.

Leave A Comment