Jumping Jack vs Plate Compactor: Key Differences

Any construction project requires the selection of appropriate equipment for soil compaction operations. The improper compaction of materials can result in multiple critical issues. Weak foundation, water accumulation and pavement damage are some of the potential issues. There are two commonly used construction compaction equipment.

For example, jumping Jack and the plate compactor. While they may appear similar, each is designed for specific tasks. Their effectiveness depends on different factors. It may include soil type and the requirements of your project. One can choose the right compaction equipment based on the soil strength.

This article is a detailed and comprehensive guide for beginners and professionals. It explains the key differences. It helps you make a smart decision. It provides detailed insight into performance, usability, maintenance, and proper application. This helps reduce errors and improve construction quality.

Contents

Understanding the Basics

A jumping jack is also known as a tamping rammer. It is a powerful compaction tool designed for challenging soil conditions. Jumping jack operates using a strong, vertical pounding force. This force is generated by an internal piston mechanism. This piston drives the machine’s footplate downward in rapid succession.

It works by striking the ground with high intensity. The footplate is narrow and long, allowing the energy to concentrate in the soil layers. The concentrated force is effective for compacting cohesive soils.

For example, clay and silt, known for their moisture-retaining properties. These soils resist compaction because of their fine particles and water content.

They require a more forceful and penetrating approach. The jumping jack excels in these conditions by delivering repeated, high-impact blows. These blows push air and water out of the soil and pack the particles tightly.

It is ideal for trench work, foundation backfills, and other confined areas. where precision and deep compaction are critical.

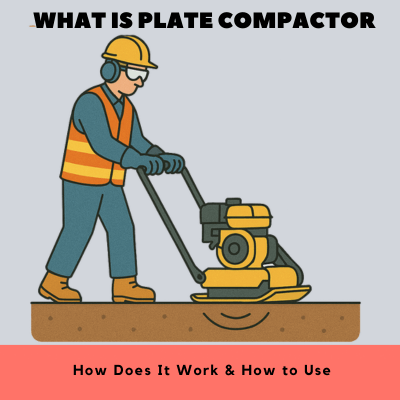

In contrast, the plate compactor functions using a different method. It features a broad, flat steel plate that produces rapid vibrations. These vibrations are produced while moving in a forward motion.

Vibrations cause the soil particles to rearrange and settle closer together. It effectively reduces air gaps and increases density.

The plate compactor is best suited for granular soils and crushed stone. These soils have larger, loose particles and respond well to vibration rather than impact.

This type of compaction creates a smooth and even surface. So, it is a preferred choice for bases for patios, driveways, sidewalks, and asphalt layers. Its wider coverage also makes it more efficient for open, flat areas.

Excellent surface uniformity is essential in projects demanding a level and stable foundation. The plate compactor provides this excellence.

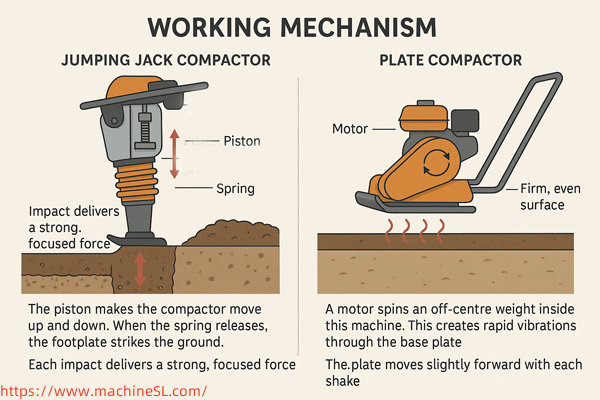

Working Mechanism

The jumping jack compactor uses a piston powered by an engine. This piston makes the compactor move up and down. For this, the piston compresses the spring connected to the footplate. When the spring releases, the footplate strikes the ground.

Each impact delivers a strong, focused force. The narrow footplate directs energy into a small area. This helps break up soil clumps and forces out trapped air and water.

The result is deep, dense compaction. This compactor is best suitable for heavy soils like clay and silt. These soils are hard to compact using vibration alone. The jumping jack is ideal for deep trenches, narrow spaces, and areas needing structural support.

The plate compactor works differently. It uses vibration instead of impact. A motor spins an off-centre weight inside the machine. This creates rapid vibrations through the base plate. The plate also moves slightly forward with each shake. These vibrations loosen the soil particles.

The weight of the plate presses them tightly together. This creates a firm, even surface. The plate compactor provides optimal results for sandy or granular soils. The open and flat areas, i.e., patios, driveways and walkways, are compactable using plate compactors.

It compacts shallow layers quickly and smoothly. It is less disruptive than a jumping jack. This makes it ideal for finish layers and surface preparation.

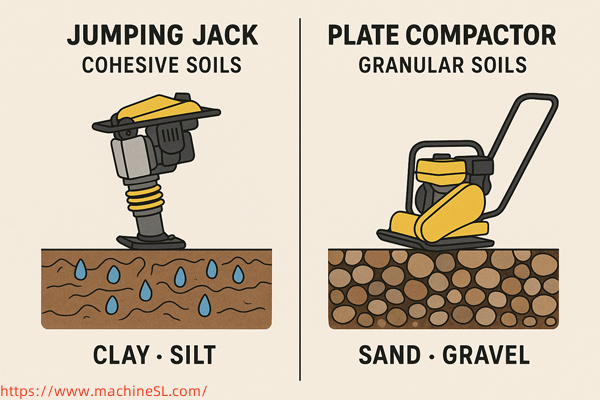

Soil Suitability

Jumping jacks are best for cohesive soils. These soils include clay and silt. Cohesive soils have small, sticky particles. They tend to hold water tightly. When wet, they become heavy and dense. They are difficult to compact using vibration alone. These soils resist movement and need a strong force to settle.

A jumping jack delivers the force. Its impact pushes out air and water. Each strike compacts the soil in layers. Moist soils respond well to the sharp, pounding action. This makes jumping jacks ideal for trenches, backfills, and confined spaces.

They work especially well where deep, tight compaction is needed. Cohesive soils may shift or settle over time without proper compaction.

However, Plate compactors are great for granular soils. This soil comprises coarser particles, which are a larger particles.

Granular soils comprise coarse particles, i.e., sand, gravel and crushed stone materials. Soil particles of this type do not have enough cohesive strength like clay and silt. Instead, they shift easily when vibrated. Vibration helps the particles slide and lock into place.

A plate compactor uses this motion to reduce air gaps. It presses the soil down in a smooth, even layer. Dry or loose soils compact faster with this method. The machine moves forward as it vibrates, covering more area. It works best on open, flat ground.

Examples include road bases, patios, and walkways. It also leaves a level surface, which is important for finishing layers. Plate compactors are efficient and easy to operate on these types of soils.

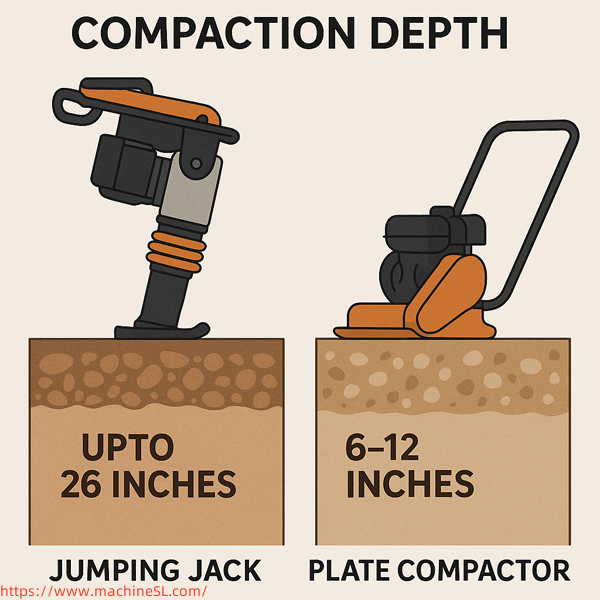

Compaction Depth

Jumping jacks are built for deep compaction. They can compact soil up to 26 inches deep. This depth can vary. It depends on the soil type, moisture content, and machine power. Cohesive soils like clay need more force. The jumping jack delivers strong, vertical blows. These blows drive the energy deep into the soil.

The narrow footplate helps focus the impact. This deep reach is very useful. It works well in trench compaction and foundation subgrade preparation. These are places where solid support is critical.

Without deep compaction, the ground may shift over time. That can cause cracks or structural damage. Jumping jacks help build strong, stable layers from the bottom up.

Plate compactors provide shallow compaction. They typically reach 6 to 12 inches deep. The exact depth depends on soil texture and machine size. Though they do not compact deeply, they are very efficient. They can cover a large area quickly. This makes them perfect for surface compaction.

They are ideal for layered compaction. Workers can compact one layer at a time. Then add the next layer and compact again.

This process builds up a stable base. Plate compactors are useful for compaction of roads, paved walkways, driveways, and patios. They help create smooth, even surfaces.

Their wide plates glide over the soil with ease. They are less aggressive than jumping jacks. This makes them better for final layers and finishing work. When working on top layers, a plate compactor gives better results.

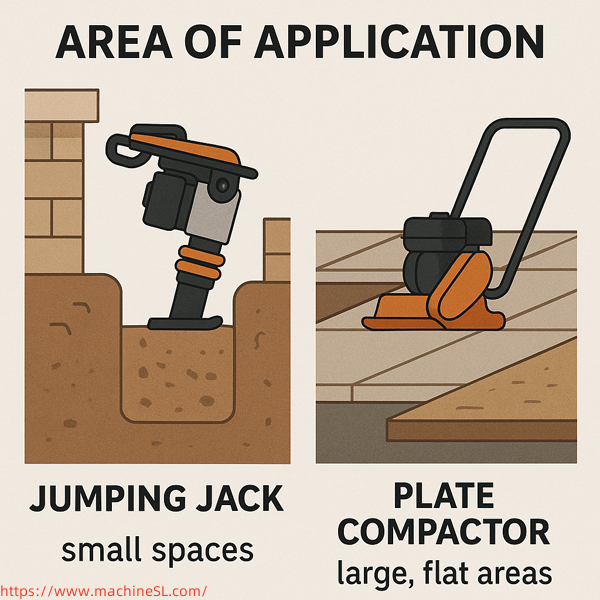

Area of Application

Jumping jacks are ideal for small spaces. Use them in trenches or near foundations. They are also good around posts and in corners. Their design allows them to reach tight areas where other machines cannot fit.

Plat compactors work best on large and flat areas. These should be used for driveways, sidewalks, and patios, etc. They work fast and make smooth surfaces. It helps in reducing material shifting and ensures better bonding between paving layers.

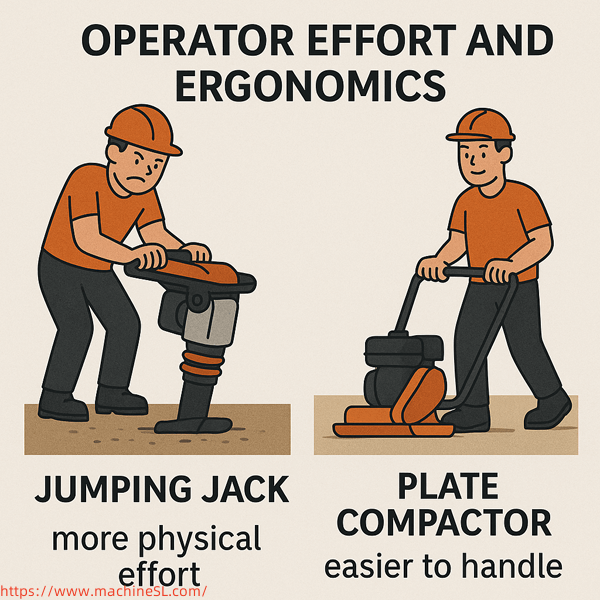

Operator Effort and Ergonomics

Jumping jacks require more physical effort to operate. They move with strong, vertical force. The machine bounces and shakes with each impact. This constant motion is hard on the body.

The operator must hold and guide the machine while it jumps. It can be tough to control, especially in rough or narrow spaces. The vibrations move through the handles to the arms. With time, it can lead to fatigue and discomfort for the operator.

However, long working hours on jumping jacks can cause muscle strain or joint pain. This is worse if the machine lacks proper ergonomics. Heavy models add even more stress. The operator must also lift and reposition the machine frequently. This adds to the physical workload.

Plate compactors are much easier to handle. They move forward in a smooth, steady motion. Some models are self-propelled, requiring little effort to guide. The user simply walks behind and steers.

Most machines have padded, vibration-reducing handles. These handles absorb much of the shaking. This protects the hands and arms. It also improves operator comfort during long jobs.

Plate compactors are easier to control on flat surfaces. They glide over the soil with minimal resistance. Low resistance also reduces fatigue and leads the operator to stay productive.

Since they are a popular choice for professionals and DIY users, they are significant for soil compaction. For large, open areas, the ease of use saves time and energy.

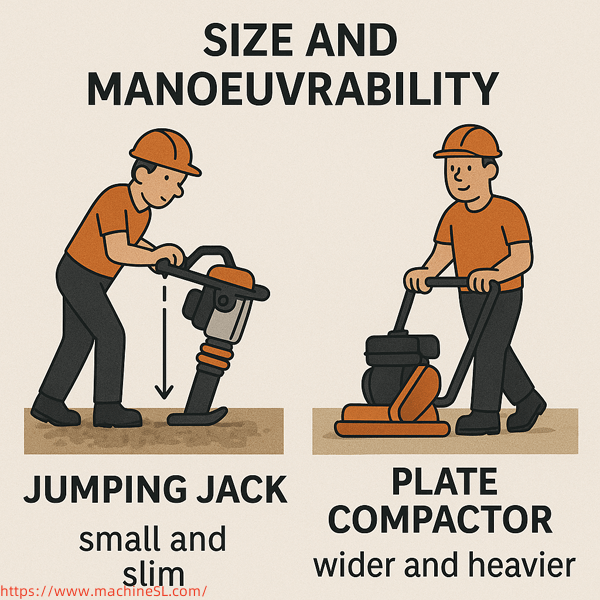

Size and Manoeuvrability

Jumping jacks are small and slim. They can fit in narrow areas. This makes them ideal for tight spaces. They can work between pipes, around edges, and under protruding structures.

Plate compactors are wider and heavier. They are better for open areas. Turning in tight spots is harder. Their size, however, gives more stability during use and better compaction coverage per pass.

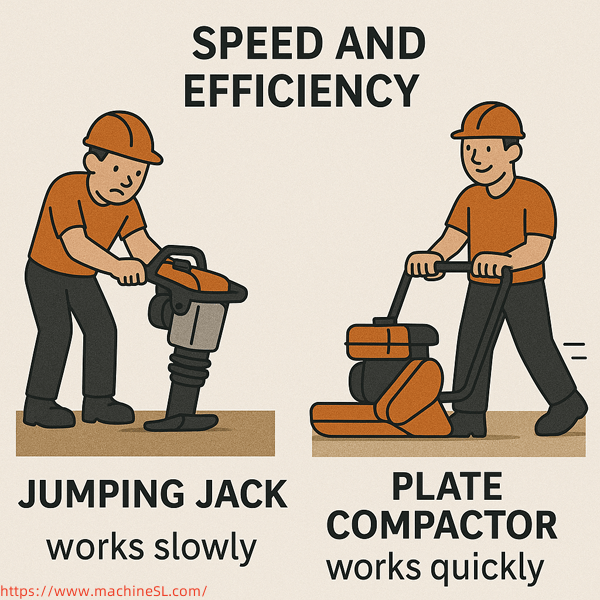

Speed and Efficiency

Jumping jacks work slowly. They need more passes. But they go deeper. They are efficient in achieving soil density but not in covering space.

Plate compactors are fast. They cover wide areas quickly. They are good for finishing large jobs. For projects with tight deadlines and open spaces, they are the best option.

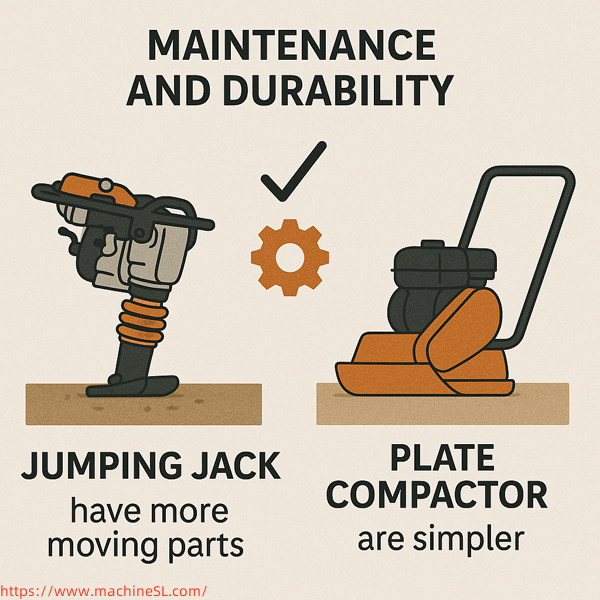

Maintenance and Durability

Jumping jacks have more moving parts. They need frequent checks. Filters, bellows, and pistons may wear out. Regular servicing ensures consistent performance.

Plate compactors are simpler. They have fewer parts. Basic cleaning and oil checks keep them running well. Their lower maintenance cost makes them appealing for long-term use.

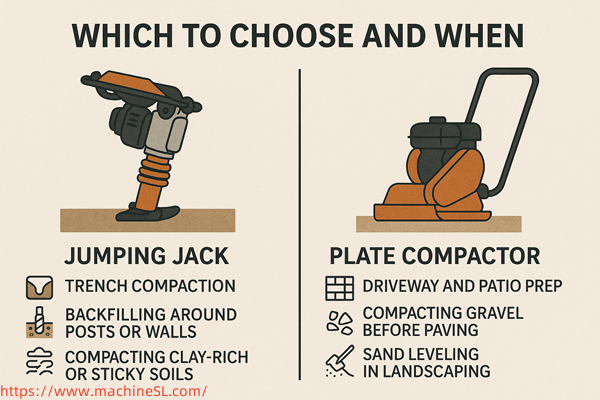

Use Cases: Which to Choose and When

Use jumping jacks for:

- Trench compaction

- Backfilling around posts or walls

- Clay-rich or sticky soils

- Foundation compaction in confined zones

Use plate compactors for:

- Driveway and patio prep

- Compacting gravel before paving

- Sand levelling in landscaping

- Preparing sub-bases for asphalt or concrete

Pro Tips for Choosing the Right Equipment

Here are some pro tips to choose the best suitable equipment for compaction.

- Know your soil. Clay needs a jumping jack. Sand and gravel need a plate compactor. Conduct a soil test if unsure.

- Check your site. Narrow spots need jumping jacks. Open areas benefit from plate compactors.

- Sometimes you need both. Use a jumping jack for the base layer. Use a plate compactor to finish the surface. This improves compaction quality and reduces settling.

- Always wear safety gear. Use hearing protection, gloves, boots, and safety glasses. Vibration gloves help reduce hand fatigue. Safety improves efficiency and prevents injury.

Alternatives and Hybrid Options

Large jobs need bigger tools. Use roller compactors for roads and wide areas. They offer both depth and surface quality.

Use a hand tamper for small jobs. It is cheap and easy to use. It is best for patchwork or very limited spaces.

Reversible plate compactors are a great combination. They go forward and backwards, offering good force and wide coverage. Hence, these are great for jobs that require flexibility and power.

Frequently Asked Questions

Can I use a plate compactor on clay?

Not effectively. Use a jumping jack for better results. Plate compactors lack the force needed to compact clay deeply.

How deep does a jumping jack compact?

Up to 26 inches, based on soil type and moisture. Multiple passes improve the final density.

Is a reversible plate compactor a good alternative?

Yes. It offers better control and works for mixed soils. It’s versatile for both forward and reverse movement.

What PPE should be worn during the operation?

Wear boots, goggles, gloves, and hearing protection. Follow the manufacturer’s safety recommendations.

Should I rent or buy for small projects?

Rent for one-time use. Buy if you work often. Compare costs over time to decide.

Leave A Comment