Power Float vs Floor Hardener: Which Offers the Best Value for Your Money

Concrete floors are an essential component of many buildings and structures, providing a durable and functional surface for a wide range of applications. When it comes to finishing a concrete floor, there are several options available, each with its own advantages and disadvantages. Two popular methods for finishing a concrete floor are power float and floor hardener.

This article compares the power float and floor hardener methods for finishing concrete floors, aiming to determine the most suitable option for specific needs. The comparison includes an evaluation of the cost-effectiveness, durability, aesthetic appeal, and maintenance requirements of both methods.

The importance of a durable concrete floor

A durable concrete floor is essential for the longevity and functionality of many buildings and structures. A well-constructed concrete floor should be able to withstand heavy traffic, impact, abrasion, and other forms of wear and tear. A floor that is not durable may crack, crumble, or otherwise fail, leading to costly repairs and downtime.

Comparison of power float and floor hardener as concrete finishing options

When it comes to finishing a concrete floor, there are several options available. Two popular methods are power float and floor hardener. Power floating involves using a machine with rotating blades to smooth and level the surface of freshly poured concrete. Floor hardener, on the other hand, is a chemical compound that is applied to the surface of the concrete to increase its durability and resistance to wear and tear.

Contents

Power Float

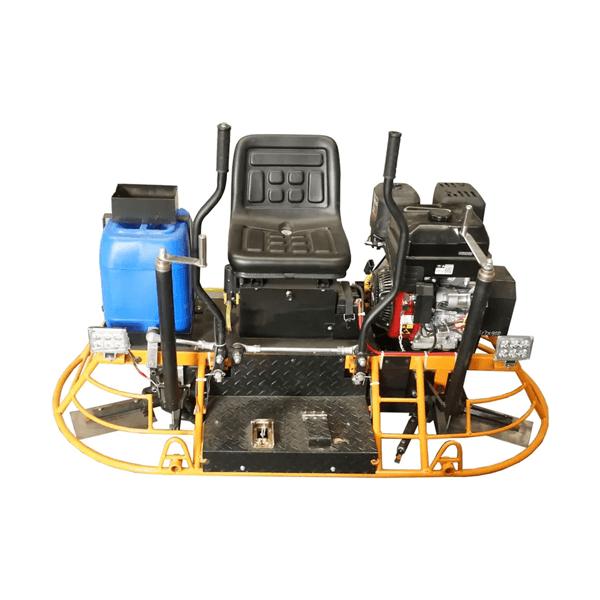

Definition and explanation of power float

Power floating is a concrete finishing technique that uses a power trowel, which is a machine with rotating blades that smooth and level the surface of freshly poured concrete. The blades of the power trowel are attached to the bottom of the machine, and they rotate at high speeds to create a smooth surface.

Advantages of power float

There are several advantages of using power float as a concrete finishing option:

- Creates a smooth surface: Power floating can create a smooth and level surface that is suitable for many applications, including industrial and commercial flooring, as well as residential driveways and patios.

- Can increase durability: Power floating can increase the durability of a concrete floor by compressing the surface and making it denser. This can help to prevent cracking and other forms of damage.

- Offers a variety of finishes: Power floating can create a variety of finishes, including a smooth finish, a swirl finish, and a salt finish. These finishes can add texture and visual interest to the surface of the concrete.

Disadvantages of power float

There are also some disadvantages to using power float as a concrete finishing option:

- Can be expensive: Power floating can be more expensive than other finishing options, such as broom finishing or acid etching.

- Requires experienced professionals: Power floating requires experienced professionals who know how to use the equipment and achieve the desired finish. Inexperienced operators can damage the surface of the concrete or create an uneven finish.

- Can take longer to complete: Power floating can take longer to complete than other finishing options, as the process requires multiple passes with the power trowel to achieve the desired finish. This can extend the timeline of a construction project.

Floor Hardener

Definition and explanation of floor hardener

Floor hardener is a chemical compound that is applied to the surface of freshly poured concrete to increase its durability and resistance to wear and tear. The compound is typically made of a mixture of cement, aggregates, and other additives that react with the surface of the concrete to create a dense, hard surface.

Advantages of floor hardener

There are several advantages of using floor hardener as a concrete finishing option:

- Increases durability: Floor hardener can significantly increase the durability of a concrete floor by creating a harder, denser surface that is more resistant to wear and tear.

- Cost-effective: Floor hardener is generally more cost-effective than power floating, as it requires less specialized equipment and can be applied quickly and easily.

- Easy to apply: Floor hardener can be applied quickly and easily by experienced professionals, making it a popular choice for large-scale commercial and industrial projects.

Disadvantages of floor hardener

There are also some disadvantages to using floor hardener as a concrete finishing option:

- Limited finish options: Floor hardener typically produces a smooth, matte finish, which may not be suitable for all applications. It may not be ideal for projects where a decorative or textured finish is desired.

- May not be suitable for all concrete types: Floor hardener may not be suitable for all types of concrete, depending on the mix design and other factors. It is important to consult with a professional to determine if floor hardener is a suitable option for a particular project.

- Can be slippery when wet: Floor hardener can become slippery when wet, which may be a safety concern in some environments. Anti-slip additives can be incorporated into the compound to address this issue, but this may increase the cost of the project.

Comparison

Durability

- Power float: Power floated concrete is generally less durable than concrete finished with a floor hardener. The surface of power floated concrete may be more susceptible to wear and damage over time.

- Floor hardener: Floor hardener can significantly increase the durability of a concrete floor by creating a harder, denser surface that is more resistant to wear and tear.

Cost

- Power float: Power floating can be more expensive than using a floor hardener due to the specialized equipment and experienced professionals required.

- Floor hardener: Floor hardener is generally more cost-effective than power floating, as it requires less specialized equipment and can be applied quickly and easily.

Time to complete

- Power float: Power floating can be a time-consuming process, especially for large projects. The concrete may need to be floated multiple times, and the process can be slowed down by adverse weather conditions.

- Floor hardener: Floor hardener can be applied quickly and easily by experienced professionals, making it a popular choice for large-scale commercial and industrial projects.

Finish options

- Power float: Power floating offers a wide range of finishes, including smooth, semi-smooth, and textured. It can also create a polished or reflective finish.

- Floor hardener: Floor hardener typically produces a smooth, matte finish, which may not be suitable for all applications. It may not be ideal for projects where a decorative or textured finish is desired.

Conclusion

In conclusion, both power float and floor hardener offer unique advantages and disadvantages when it comes to finishing concrete floors. Power float provides a smooth surface and a variety of finishes but can be expensive and time-consuming. The floor hardener, on the other hand, offers increased durability, cost-effectiveness, and ease of application, but may have limited finish options and can be slippery when wet.

When choosing between power float and floor hardener, it is important to consider factors such as the desired finish, budget, timeline, and the specific requirements of the project. For projects where a decorative or textured finish is desired, power float may be the better option, while projects with high traffic or heavy machinery may benefit from the increased durability of floor hardener.

Ultimately, the choice between power float and floor hardener should be based on the specific needs and requirements of the project.

Leave A Comment