Power Float Render: The Secret Weapon for Perfectly Smooth Finishes

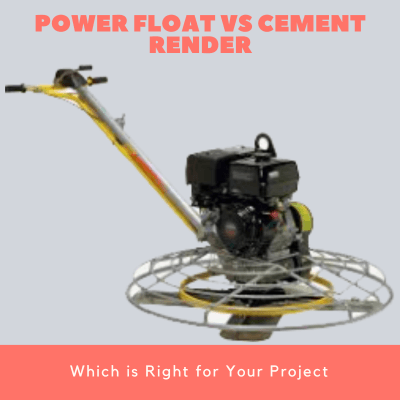

Power float render is a technique widely used in the construction industry to achieve impeccably smooth and level finishes on concrete surfaces. By employing a power float machine equipped with rotating blades or pans, skilled operators can effectively level and consolidate the concrete, resulting in a dense and durable surface. This method plays a crucial role in construction projects, as it enhances the overall quality and longevity of the concrete while providing an aesthetically pleasing appearance.

Definition and purpose

Power float render is a technique used in construction to achieve a smooth and flat finish on concrete surfaces. The purpose of power float render is to level, consolidate, and polish the concrete, resulting in a durable and visually appealing surface.

Importance in construction projects

- Power float render improves the durability of concrete by creating a dense and compact surface that is resistant to wear and tear. It reduces the risk of cracking in concrete surfaces, enhancing their longevity.

- Power float render enhances the appearance of concrete by providing a smooth and professional finish.

Contents

Understanding Power Float Render

Explanation the technology

- Power float technology involves the use of a power float machine, which is a motorized equipment designed to smooth and finish concrete surfaces.

- The machine is equipped with rotating blades or pans that level the concrete and create a smooth finish by removing imperfections and consolidating the surface.

Components and equipment used in rendering

- The primary component of power float rendering is the power float machine, which consists of a motor that drives the rotating blades or pans.

- The blades or pans are typically made of steel and can be adjusted for different angles and pressures.

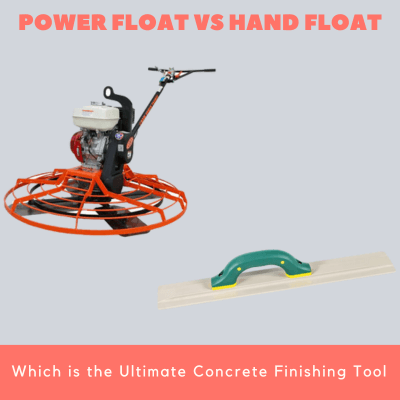

Advantages over traditional methods

- It significantly speeds up the process, allowing for larger areas to be finished quickly and efficiently.

- The power float machine creates a denser and more compact surface, resulting in increased durability and resistance to wear and tear.

- It eliminates the need for manual smoothing and reduces the risk of human error, ensuring consistent and high-quality finishes.

Preparation and Surface Readiness

Surface inspection and assessment

- Before applying power float render, a thorough inspection and assessment of the surface are crucial.

- Inspect the substrate for any cracks, unevenness, or other defects that may affect the quality of the finish.

- Identify any areas that require repair or additional preparation before proceeding with power float rendering.

Necessary surface preparation steps

- Clean the surface thoroughly, removing any debris, dirt, or loose material that could interfere with the power float render.

- Repair any cracks, holes, or damaged areas using suitable repair materials or techniques.

Ensuring proper curing of the substrate

- The substrate should have sufficient time to cure before applying power float render.

- Follow the recommended curing period for the specific type of concrete used.

Power Float Render Application Process

Selection of appropriate materials (render mix)

- Choose a render mix that is suitable for power float rendering.

- Consider factors such as the type of project, desired finish, and environmental conditions.

Mixing and consistency of the render

- Follow the manufacturer’s instructions for mixing the render mix.

- Use the appropriate ratio of water to render the mix to achieve the desired consistency.

- Ensure thorough and consistent mixing to avoid lumps or inconsistencies in the render mix.

Application techniques using power float machines

- Start by pouring the render mix onto the prepared surface in manageable sections.

- Use the power float machine to level and smooth the surface.

- Maneuver the machine in overlapping passes to ensure even coverage and consistent results.

Achieving desired thickness and texture

- Control the thickness of the render by adjusting the height of the blades or pans on the power float machine.

- Gradually build up the thickness in multiple passes, allowing the render to set between each pass.

- Monitor the texture of the surface and adjust as needed to achieve the desired smoothness or texture.

Finishing and Curing

Techniques for achieving a smooth and level surface

- Utilize the power float machine in multiple passes, adjusting the angle and pressure of the blades or pans to achieve a smooth and level surface.

- Pay attention to any remaining imperfections or inconsistencies and address them with hand tools or additional passes with the power float machine.

Proper curing methods and timeframes

- Follow recommended curing methods for the specific type of render mix used, such as applying a curing compound, covering the surface with plastic, or keeping it moist with regular water spray.

- Adhere to the recommended curing timeframe to allow the render to properly set and strengthen.

Importance of curing for long-term durability

- Proper curing is essential for the long-term durability and strength of the power float render.

- It allows the render to fully harden, reducing the risk of cracking and enhancing its resistance to wear, weathering, and other environmental factors.

Common Challenges and Troubleshooting

Identifying and addressing potential issues during application

- Monitor the application process for any potential issues such as air pockets, excessive bleeding, or uneven distribution of the render mix.

- Address air pockets by using a vibrating tool or by reapplying the render mix in affected areas.

Dealing with uneven surfaces or voids

- Fill voids with suitable repair materials and level uneven surfaces using appropriate techniques such as grinding or patching.

- Pay attention to these areas during the power float rendering process and use hand tools if necessary to achieve a consistent finish.

Solutions for achieving uniform color and texture

- Ensure consistent mixing of the render mix and use the same batch for the entire project to achieve uniform color.

- Maintain consistent application techniques and passes with the power float machine to achieve a uniform texture.

Maintenance and Longevity

Regular maintenance practices

- Regularly clean the surface of the power float render to remove dirt, debris, and stains.

- Avoid using harsh chemicals or abrasive cleaners that may damage the surface.

Repairs and patching techniques

- If the power float render develops cracks or damaged areas, use appropriate repair techniques to fix them.

- Clean the damaged area, apply suitable repair material, and smooth it to match the surrounding surface.

Extending the lifespan through proper care

- Avoid placing heavy or sharp objects directly on the power float render surface to prevent damage.

- Regularly check for any signs of moisture or water infiltration that could lead to deterioration.

- Consider applying a protective sealer to the power float render surface to enhance its durability and resistance to staining.

Safety Considerations

Personal protective equipment (PPE) requirements

- Operators and workers involved in power float rendering should wear appropriate PPE, including safety goggles, gloves, and ear protection.

- Depending on the specific job site requirements, additional PPE such as protective clothing, respiratory protection, and safety footwear may be necessary.

Safe handling of power float equipment

- Operators should receive proper training on the safe operation of power float machines.

- Ensure that the power float machine is in good working condition and all safety features are functional.

Ensuring a safe working environment for operators and others

- Clear the work area of any tripping hazards, debris, or obstacles that may pose a risk to operators or others.

- Implement proper signage, barricades, or safety barriers to prevent unauthorized access to the work area.

Case Studies and Examples

Showcase of successful power float render projects

- A large-scale commercial office building in Shanghai underwent a power float render project to enhance concrete floors. Power float technology efficiently leveled and smoothed the concrete surfaces, resulting in a sleek finish. Power float render provided a dense and durable surface, capable of withstanding heavy foot traffic.

- Industrial warehouse in Guangzhou underwent a power float render project for its concrete flooring. Power float technology quickly and effectively leveled the uneven surfaces, creating a smooth finish. The power float render enhanced the durability and strength of the concrete, suitable for industrial operations.

- The renovation project of a shopping mall in Beijing included a power float render for its common areas. Power float technology provided a consistent and visually appealing finish to the concrete floors. The power float render enhanced the overall ambiance and attractiveness of the shopping mall.

Before and after comparisons highlighting the benefits

- Before: Uneven and rough concrete floors affecting the overall appearance and functionality of the office building.

- After: Power float render transformed the floors into a sleek and level surface, greatly enhancing the aesthetic appeal and providing a professional finish.

- Benefits: Improved visual appeal, increased durability, and enhanced functionality of all these buildings.

Lessons learned from real-world applications

- Thorough surface inspection and preparation are crucial to ensure a seamless and consistent power float render application.

- Proper curing techniques and timeframes are essential to achieve the desired strength and durability of the power float render.

- Understanding the specific requirements and operational needs of the industrial space is key in determining the appropriate power float render thickness and surface finish.

Conclusions

In conclusion, power float render is a highly advantageous technique for construction projects. Its ability to deliver perfectly smooth finishes, enhance durability, and improve the overall appearance of concrete surfaces makes it a valuable tool in industry.

By adopting power float render, construction professionals can achieve superior results, meeting customer expectations and reducing long-term maintenance needs. Encouraging further exploration of this technique, the future of power float render holds potential for advancements in equipment, materials, and application techniques, ensuring its continued relevance and widespread adoption.

With its proven benefits and promising prospects, power float render remains a secret weapon for achieving flawless and long-lasting finishes in construction projects.

Leave A Comment