Road Roller vs. Steamroller vs. Bulldozer: Final Showdown

The construction process involves the use of various equipment. Depending on the scale of the project, heavy equipment are used to deliver higher quality works and reduce construction time.

Some of the most popular construction equipment are road rollers, steam rollers, and bulldozer. The equipment are used in road construction, structural construction, and landscaping works. A road roller comprises of a weighted drum attached to a cabin with an engine.

The cabin provides control and operation area while the engine generates power used to move the drum. Road rollers are used in compaction of construction materials to required densities and load bearing capacity.

Steam rollers and designed to function as road rollers; however, they are driven by steam engines instead of diesel engines as in road rollers. The bulldozer is essential at the earliest stages of construction. Also known as the dozer, this engine-powered equipment is used to push soil to required places.

It moves on continuous racks making it applicable for harsh working conditions. However, modern designs incorporate rubber tires for easy maneuverability.

Importance of these machines in construction and roadwork

The bulldozer is used to clear construction sites. It removes the top soil leaving stable ground on which structures and roads can be built. Road rollers are used for compaction of base and subbase layers in road construction. In structural construction, road rollers are used to compact the ground for construction of foundations.

Compaction improves the density and load bearing capacities of roads and structural foundations. Steam rollers play the same role as road rollers in the construction industry.

Contents

Road Roller

A. Definition and purpose

Road rollers are engine powered equipment with a weighted drum at the front, back, or at both ends used to compact construction material. The equipment is driven over material exerting compaction force due to the weight of the drum. There are various types of road rollers; the choice of which to use is guided by project requirements and scale of the project.

B. Types of road rollers

1. Static road rollers

These are road rollers with drums at the front or back of the cabin and solely relies on the weight of the drum to exert compaction force. Static rollers are good for granular materials such as ballast. They provide a smooth finish; thus, they are used in compacting asphalt concrete and the base layer in road construction.

2. Vibratory rollers

These are rollers with drums mounted at the front or back of the cabin. The drums are fitted with suspended weights that vibrate when triggered. The vibrations are transmitted to the construction material through the drum surface. Vibratory rollers have a smooth drum and are used for compacting cohesive soils with a high water and air retention rate.

3. Pneumatic rollers

With this type of road rollers, the drums are replaced with air-filled rubber tires. This roller type relies on the weight of the engine and cabin to exert compaction force. The rubber tires prevent damage to surfaces that would otherwise be cased by drums on static and vibratory rollers. For this reason, they are used for smoothing surfaces in road construction.

C. Applications and advantages of road rollers

Road rollers are used to compact soil, gravel, asphalt, and concrete during road construction and maintenance. Their application ensures better stability and durability of the road surface. Advantages include improved load-bearing capacity, increased resistance to settlement and deformation, and enhanced water drainage. Road rollers also help in achieving uniform compaction, reducing the risk of potholes and other road surface defects.

D. Limitations and considerations

The size and weight of road rollers make them suitable for compacting soil and asphalt but not for maneuvering in tight spaces or delicate areas. Secondly, their operation requires skilled personnel due to the potential risks involved, such as collisions and rollovers. Additionally, road rollers can cause noise pollution and vibrations that may disturb nearby residents or affect nearby structures. Careful planning, adherence to safety protocols, and appropriate usage in designated areas are essential to minimize these limitations and considerations.

Steam Roller

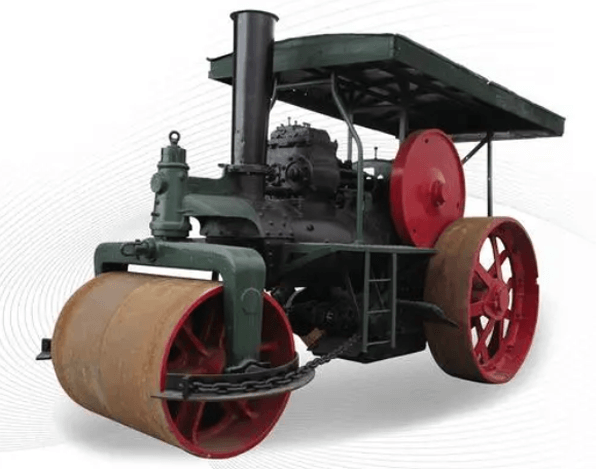

A. Definition and application

A steam roller consists of a large cylindrical roller at the front and a steam engine at the back. Steam rollers are used primarily for compacting and leveling surfaces during road construction and maintenance. Their heavy weight and rolling action help to compress soil, asphalt, or other materials, ensuring a smooth and stable road surface. Steam rollers were commonly used in the past but have been largely replaced by modern diesel-powered road rollers.

B. Historical significance and evolution

The steam roller holds significant historical importance in the development of road construction machinery. It emerged in the late 19th century as a groundbreaking innovation, replacing horse-drawn rollers. Steam rollers revolutionized road building by increasing efficiency and reducing labor requirements. Over time, advancements in technology led to the evolution of steam rollers, with improvements in power, design, and functionality. However, with the advent of diesel-powered road rollers in the 20th century, steam rollers gradually became obsolete, although they remain an important milestone in the evolution of construction equipment.

C. Applications and advantages

Steam rollers have several applications and advantages. They are primarily used for compacting and leveling surfaces during road construction and maintenance. The heavy weight and rolling action of steam rollers effectively compress soil, asphalt, or other materials, ensuring a durable and smooth road surface. The advantages of steam rollers include their high compaction power, faster compaction, and their historical significance as a pioneering technology in road construction machinery.

D. Differences and similarities with road rollers

The main difference between steam rollers and road rollers is their power source. Steam rollers are operated using steam power, while road rollers are typically powered by internal combustion engines, such as diesel engines. However, both types of rollers serve the same purpose of compacting and leveling surfaces during road construction. They share similarities in terms of their heavy weight, rolling action, and the ability to ensure a smooth and stable road surface, albeit with different power mechanisms.

E. Limitations and considerations

When using steam rollers, several limitations and considerations should be taken into account. Firstly, steam rollers require a water source and fuel, making them more complex to operate and maintain compared to modern road rollers. They also have a slower operational speed. Additionally, steam rollers produce emissions and require ventilation to prevent exposure to harmful gases. The high maintenance and operational costs associated with steam rollers should be considered, including the need for trained personnel and regular servicing of the steam engine.

Bulldozer

A. Definition and features

A bulldozer is a heavy, engine powered equipment with a large metal blade at the front and a robust crawler track system. It is primarily used for pushing, leveling, and moving large quantities of earth, rocks, debris, or other materials during construction, excavation, and land clearing projects. Bulldozers are essential in various applications, such as road building, mining operations, forestry, land development, and building site preparation. They provide efficient and precise earthmoving capabilities, making them indispensable in heavy-duty construction and land management tasks.

B. Types of Bulldozers

Bulldozers are classified depending on how they move and navigate. There are two main types of bulldozers; the crawler and the wheeled bulldozer. Crawlers are fitted with continuous tracks that are moved by gears to generate motion. They are most applicable in challenging terrains since they are not stuck easily. Wheeled bulldozers are equipped with a set of strong rubber tires. This is used in fairly favorable conditions and is easy to maneuver. Wheeled bulldozers are advantageous in areas that require protecting the ground.

C. Applications and advantages

Bulldozers have a wide range of applications and offer several advantages. They are extensively used in construction, mining, and agriculture for tasks like earthmoving, grading, and leveling. Bulldozers provide exceptional pushing power, making them efficient in moving large volumes of materials. They can operate in challenging terrains, such as uneven surfaces or soft soils. Their versatility, durability, and ability to handle heavy loads make them indispensable in various industries for efficient and effective land management.

D. Differences and similarities with road rollers and steam rollers

The main difference between the three equipment is their applications and general outlook. Unlike rollers, bulldozers are not used for compaction. Their weight and general design do not allow effective compaction. While rollers have a drum attached to either the front or rear, bulldozers have strong metal blade attached to the front and a rake to the back.

E. Limitations and considerations

When using a bulldozer, certain limitations and considerations must be taken into account. Bulldozers have a large turning radius, making them less maneuverable in tight spaces. The operator requires training and experience to operate the machine safely. Environmental factors such as slopes, unstable ground, or adverse weather conditions can affect performance. Additionally, proper maintenance and regular inspections are crucial to ensure the machine’s optimal functioning and minimize the risk of breakdowns or accidents.

Comparison

A. Key differences in design and functionality

Road rollers are designed for compacting and leveling surfaces during road construction. Steam rollers are a type of road roller powered by steam, while modern road rollers use internal combustion engines. Bulldozers, on the other hand, are equipped with a large front blade and are primarily used for pushing or grading materials, such as soil or debris. Bulldozers are more versatile in tasks such as excavation and land clearing compared to rollers.

B. Operational differences and use cases

Road rollers are used for compacting and leveling surfaces in road construction and maintenance projects. They operate by rolling over the surface to compress the materials.

Steam rollers, a type of road roller, use steam power for operation. They were commonly used in the past but have been largely replaced by modern diesel-powered road rollers.

Bulldozers, equipped with a large front blade, are versatile machines used for pushing, grading, and clearing materials. They are commonly employed in construction, mining, and land development projects.

C. Performance and efficiency comparisons

In terms of performance and efficiency, modern road rollers and bulldozers generally outperform steam rollers. Road rollers and bulldozers are equipped with advanced technologies, such as variable speed controls, precise compaction measurements, and advanced hydraulic systems, making them more efficient in their respective tasks. Bulldozers have greater versatility and power for pushing and grading, while road rollers excel in compacting and leveling surfaces with higher precision and efficiency.

D. Cost considerations

When considering the costs of road rollers, steam rollers, and bulldozers, several factors come into play. Firstly, the initial purchase cost varies depending on the type, size, and brand of the machine. Additionally, operational costs such as fuel or steam consumption, maintenance, and repairs should be considered. Bulldozers may have higher fuel consumption due to their larger engines. Furthermore, availability of spare parts and the expertise required for maintenance and repairs can also impact the overall cost of ownership for these machines.

E. Environmental impact and sustainability

Road rollers, steam rollers, and bulldozers have environmental impacts due to their fuel consumption, emissions, and noise pollution. To mitigate these impacts, newer models often meet stricter emissions standards and incorporate fuel-efficient technologies. Additionally, sustainable practices such as proper maintenance, optimizing equipment usage, and adopting eco-friendly fuels can help reduce their environmental footprint.

Conclusions

Road rollers, steam rollers, and bulldozers play crucial roles in various construction and road maintenance projects. While each has its unique design, functionality, and considerations, they contribute to the development of infrastructure. Understanding their limitations, performance, costs, and environmental impact enables informed decision-making for efficient and sustainable construction practices.

Technological advancements have resulted in creation of models that are easy to operate, deliver efficient results, and guarantee comfort for the operator. Future road rollers and bulldozers will be more eco friendly.

Leave A Comment