Spray Plaster: 6 FAQs You Should Know

Plastering is not only to prepare the surface for the before painting or giving it a smoother finish but also to protect the surfaces from deterioration.

It serves as an added protection of the surface against external elements. It keeps your walls, ceiling or other surfaces longer.

The initial process of plastering is preparation, application of thin cement mortar to cover the rough surfaces or even the uneven surfaces and lastly some other necessary finishes.

This makes your surface more appealing, cleaner and durable. And with the advancement of technology, so does the application of plaster.

Contents

Can You Spray Plaster

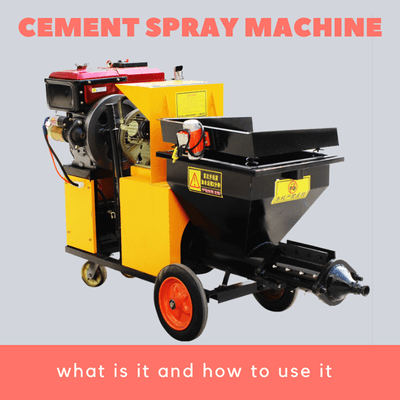

You might be in shock but as any other construction method, so does the plaster application. Plaster can be applied through intended spray machine. Plaster spraying allows you to give a finished look without the need of a hand float. The process of spraying plaster can be quicker than by hand but can give you the same, or even better quality of plaster finish.

Plaster spraying provides faster work with lesser workers involved, can be more consistent once mastered with the right equipment and mixture ratio and can cure faster than the traditional way of plaster application. Plaster spraying also has lesser chances of cracks due to faster curing which means lesser shrinkage.

Spray plaster can be of smooth finish for a sleek and neat look of the surfaces, textured and colored finish which gives your surface appealing depending on your aesthetic.

Spray plastering can be done in different types. It can be through a pneumatic sprayer which is the most common and easiest to use. It only requires an air pressure and air hose to do the job.

Next is, screw pump which the plaster is pump into the spray gun with a large nozzle where the plaster will pass through. These pump is not suitable for solvent-based materials as it has rubber stator.

Another would be peristaltic pump which has a peristaltic pump that requires a compressed air to produce a spray. This pump can be used for different type of plaster finish like textured coating providing that they are not solvent-based materials. Lastly is the piston pump.

The piston pump is used for smooth finish with sufficient pressure without the need of compressed air. The challenge with this equipment is it has lower volume. The good thing with this is that compared with the first two pumps, a piston pump can be used for solvent-based materials.

How Does Spray Plastering Work

Spray plastering is like spraying paint. Just like the equipment used for spraying paint, you will need to connect the hopper to the sprayer. After connecting these, make sure that everything is tight and sealed to not allow any leak to happen during the application.

After sealing the hopper and the sprayer, feed the plaster material unto the hopper. Adjust the sprayer into the consistency of the material. Make sure that the plaster material is in the right consistency to achieve the right finish of the surface.

After these steps, align the nozzle to its working condition and do a test spray to make sure that everything is working fine and that the consistency and volume of plaster is right before spraying it to the work surface. Now that you’ve tested the sprayed plaster, spray it to the work surface in even rows with a consistent distance away from the surface.

The main concern during the spray plaster is the sides or the edges which are hard to apply spray plaster. To address this, make sure that as your apply in the corners, you must not forget the sides at the same time to have an even and uniform plaster finish.

Once done, smoothen the surface using a trowel or spatula to give in a final finish. After it has cured, apply the second coat and you’re done!

Can You Spray Plaster With Airless Paint Sprayer

There can be airless spray that can work for both paint and plaster but it needs to be modified to achieve the right finish of the surface.

The airless spray can be used for wide range of coating material whether for interior or exterior finish. It can be used for enamels, primer, and different types of paint, latex, resins and many more. If airless spray will be used for spraying plaster, it is best to provide a gravity tank.

The provision of gravity tank is because plaster can be of different viscosity or density compared to its intended material which are paint.

How Long Does It Take To Spray Plaster

Application of plaster finish can only take for a couple less hours compared to traditional method depending on the area of surface application. Some spray plaster promises to finish a surface of 100 square meter for 27 minutes.

Plaster should cure for at least 12 hours and up to 24 hours before applying the decorative finish. Plaster thickness can range from 1mm to 1.5 depending on the material of surface. Plastering should also be done in multiple coats to ensure the flatness and smoothness of the surface.

Spray plaster is more consistent, even and uniform finish that can be done faster than the conventional method, fast enough to proceed on the decorative finish.

Is Spray Plastering Any Good

Traditional way of plaster application can be time consuming when done. If you want to have a faster application with lesser workforce, spray plastering is right for you. Lesser workers means lesser labor cost.

Mechanizing the spray application also lessens the wastage during the application. Spray plastering also lessens the cracks on the surface. The important things to considering during the spray plastering is mastery of works and the plaster mixture.

Once these things are right, your spray plastering gives you no problem.

How Do You Spray Plaster A Ceiling

Plastering a ceiling, wall or other surfaces do not differ from each other. You will need to connect the hopper to the sprayer. After connecting these, make sure that everything is tight and sealed to not allow any leak to happen during the application.

After sealing the hopper and the sprayer, feed the plaster material unto the hopper. Adjust the sprayer into the consistency of the material. Make sure that the plaster material is in the right consistency to achieve the right finish of the surface.

After these steps, align the nozzle to its working condition and do a test spray to make sure that everything is working fine and that the consistency and volume of plaster is right before spraying it to the work surface.

Now that you’ve tested the sprayed plaster, spray it to the work surface in even rows with a consistent distance away from the surface.

Conclusion

It is known that for construction job, time is the most important. Time decides the cost of the project. Mechanizing some construction methods helps you finish the job quicker and have a better quality compared with the traditional method. One of these mechanized and improved construction method is spraying plaster.

The purpose of plaster is to level and give it an even and uniform finish before applying the decorative plaster. The plaster spraying does these things in a shorter span and lesser workforce.

These allows to proceed with other work on the surface better and faster.

Leave A Comment