Trowel or Float Master Concrete [Difference & Overlapping]

When it comes to working with concrete, two essential tools that often come into play are the float and the trowel. While they may seem similar at first glance, understanding their differences and unique characteristics is crucial for achieving the desired results in concrete finishing.

A float is a versatile tool used for initial surface leveling and creating a textured finish, while a trowel is designed for achieving a smooth and polished surface. In this post, we will explore the distinctions between a float and a trowel, their overlapping use cases, and the importance of selecting the right tool for specific concrete projects.

By gaining a comprehensive understanding of these tools, you can enhance your craftsmanship and achieve professional-quality concrete finishes.

Definition of a float:

- A float is a concrete finishing tool with a flat, rectangular, or round blade.

- It is typically made of wood, magnesium, or aluminum.

- Floats are used for leveling and smoothing the surface of freshly poured concrete.

Definition of a trowel:

- A trowel is a handheld tool with a flat, rectangular blade made of steel or other durable materials.

- It is used for finishing and polishing concrete surfaces.

- Trowels come in various sizes and are commonly used in small to medium-sized concrete projects.

Understanding the difference:

- Understanding the difference between a float and a trowel is crucial for proper concrete finishing.

- Each tool has its own specific purpose and application in the concrete construction process.

- Knowing when to use a float and when to switch to a trowel ensures the desired result of a smooth and level concrete surface.

Contents

Float

Description of a float

- A float is a concrete finishing tool with a flat, rectangular, or round-shaped blade.

- It typically features a handle attached to the top for easy maneuverability.

- The blade of a float is usually made of wood, magnesium, aluminum, or other materials.

Purpose of a float

- The primary purpose of a float is to level and smooth freshly poured concrete.

- It helps to remove imperfections, fill in voids, and create a uniform surface.

- Floats are particularly useful in the early stages of concrete finishing.

Common materials used for floats

- Wood floats: These are often made of hardwood, such as maple or mahogany.

- Magnesium floats: Lightweight and durable, these floats are commonly used for larger concrete areas.

- Aluminum floats: These floats offer similar properties to magnesium floats but may be more affordable.

Applications of a float

- Floats are used for leveling and smoothing concrete slabs, sidewalks, driveways, and other flat surfaces.

- They are effective in removing excess water from the surface and consolidating the concrete.

Examples of float variations

- Bull float: A large float, often with an extension handle, used for smoothing larger areas of concrete.

- Magnesium float: A lightweight float made of magnesium, known for its strength and smooth finish.

Trowel

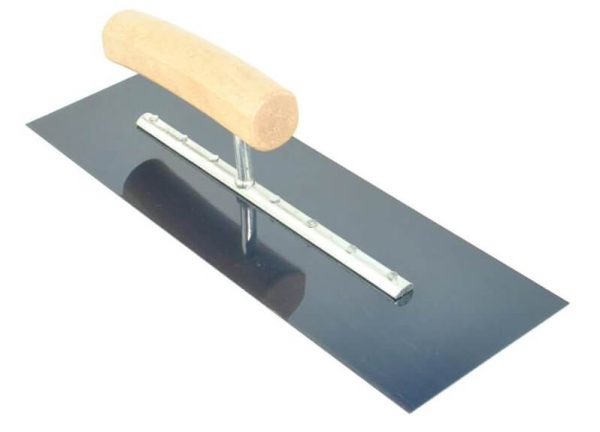

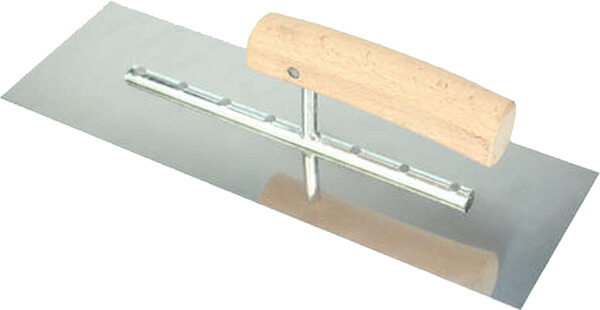

Description of a trowel

- A trowel is a handheld tool with a flat, pointed, or curved blade.

- It is typically made of steel or stainless steel and has a handle for gripping and control.

Purpose of a trowel

- The primary purpose of a trowel is to apply and finish mortar or concrete.

- It is used for spreading, leveling, and shaping the material in various construction and masonry tasks.

Common materials used for trowels

- Steel: Trowels made of steel are durable and suitable for heavy-duty applications.

- Stainless steel: These trowels resist rust and corrosion, making them ideal for working with wet materials.

Applications of a trowel

- Trowels are commonly used in masonry work, such as bricklaying, plastering, and tile installation.

- They are essential for smoothing and shaping surfaces, filling joints, and achieving precise finishes.

Examples of trowel variations

- Finishing trowel: A flat-edged trowel used for creating a smooth, polished surface on concrete or plaster.

- Pointing trowel: A small, triangular-shaped trowel with a pointed tip, used for applying and shaping mortar joints.

Key Differences between a Float and a Trowel

Design and shape differences

- Float: Typically, larger in size with a rectangular or square-shaped flat surface.

- Trowel: Generally smaller in size with a flat, pointed, or curved blade.

Functionality and purpose distinctions

- Float: Primarily used for initial concrete surface leveling, smoothing, and removing imperfections.

- Trowel: Primarily used for applying, spreading, and finishing mortar or concrete.

Typical applications and use cases

- Float: Used in early stages of concrete work, such as floating the surface after pouring and screeding.

- Trowel: Used in later stages of concrete work, after floating, to further refine and finish the surface.

Materials and construction variances

- Float: Often made of lightweight materials like wood, aluminum, or magnesium.

- Trowel: Typically made of heavier and more durable materials like steel or stainless steel.

Overlapping Use Cases

Situations where both a float and a trowel be used

- Finishing concrete surfaces: Both a float and a trowel may be employed in the final stages of concrete finishing to achieve the desired smoothness and texture.

- Repair and patching work: When repairing or patching concrete surfaces, using a float to level and smooth the repaired area and a trowel to blend it with the surrounding surface can result in a seamless finish.

Complementary roles of a float and a trowel in certain tasks

- Texture creation: While a float is typically used to achieve a consistent and level surface, a trowel can be employed to create unique textures and patterns on the concrete, adding decorative elements to the finished product.

- Edge and corner work: Floats are commonly used for larger areas, but when it comes to working on edges and corners, a trowel’s smaller size and shape make it more suitable for precise control and maneuverability.

Conclusions

In conclusion, understanding the differences between a float and a trowel is essential for anyone involved in concrete work. While floats are primarily used for initial surface leveling and finishing, trowels excel in achieving a smooth and polished concrete surface.

By selecting the right tool for the job, whether it’s a float or a trowel, individuals can ensure optimal results and enhance the quality of their concrete work. Additionally, recognizing the overlapping use cases of floats and trowels allows for their complementary roles in certain tasks, providing versatility and efficiency.

Ultimately, being knowledgeable about these tools empowers individuals to make informed decisions, leading to successful and professional outcomes in their concrete projects.

Sources:

Leave A Comment