How to Adjust Trowel Machine Blades: Step-by-Step [GIF & Video]

In the field of civil engineering, trowel machines play a vital role in achieving smooth and polished concrete surfaces. However, the proper adjustment of trowel machine blades is paramount to ensure consistent and high-quality results.

By understanding the significance of blade alignment, height, and angle adjustments, civil engineers can optimize the performance of trowel machines, improve efficiency, and enhance the overall aesthetics of concrete finishes.

In this article, we will provide a step-by-step guide to adjusting trowel machine blades, along with safety precautions and maintenance tips to help civil engineers master this essential skill.

Explanation of trowel machine blades

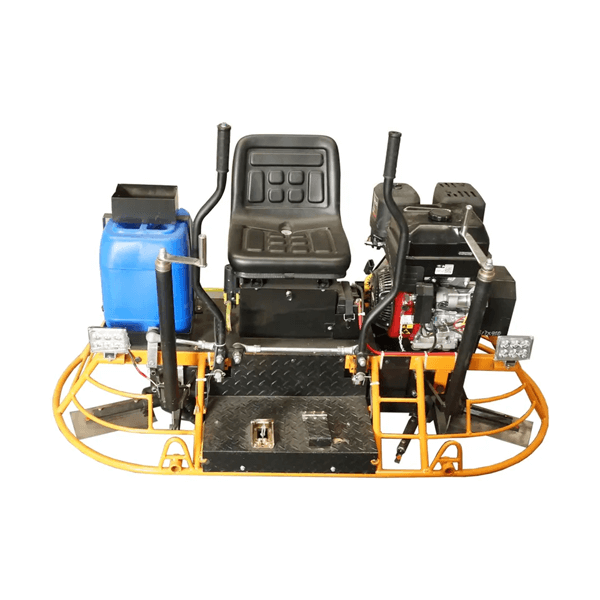

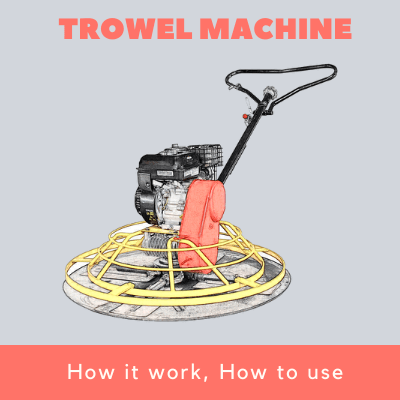

- Trowel machine blades are an essential component of power trowels used in concrete finishing.

- These blades, typically made of steel, are attached to the rotating arms of the trowel machine.

- They are responsible for smoothing and leveling the concrete surface, creating a polished and finished appearance.

Importance of properly adjusting the blades

- Properly adjusted blades ensure an even and consistent finish across the concrete surface.

- Improperly adjusted blades can result in an uneven finish, causing variations in the concrete’s smoothness and appearance.

- By adjusting the blades correctly, you can optimize the performance of the trowel machine, achieving the desired surface finish efficiently.

- Well-adjusted blades also minimize the risk of damage to the trowel machine and ensure longevity by reducing unnecessary stress on the equipment.

Contents

Safety Precautions

Safety gear requirements

- Prioritize safety by wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses.

- PPE helps protect against potential hazards like sharp edges, flying debris, and accidental contact with moving parts.

- Ensure that all operators and personnel involved in the adjustment process are wearing the necessary safety gear.

Turning off the machine before making adjustments

- Before starting any maintenance or adjustment work, always turn off the trowel machine.

- This prevents accidental activation of the blades while making adjustments, reducing the risk of injuries.

- Additionally, allow the engine to cool down completely before working on the machine to avoid burns or other heat-related accidents.

Tools Required

List of necessary tools

- Adjustable wrench

- Screwdriver (Phillips or flathead, depending on the machine)

- Measuring tape or ruler

- Level (spirit level or laser level, depending on preference)

- Allen wrench or hex key set (size may vary depending on the machine)

Explanation of each tool’s purpose

- Adjustable wrench: Used for loosening and tightening bolts or nuts during blade adjustment.

- Screwdriver: Depending on the machine, either a Phillips or flathead screwdriver may be needed to adjust certain components or fasteners.

- Measuring tape or ruler: Used to measure and ensure accurate adjustments, such as blade clearance or pitch.

- Level: A level is used to ensure that the blades are properly aligned and level, ensuring an even finish across the concrete surface. It can be a spirit level or a laser level, depending on personal preference and availability.

- Allen wrench or hex key set: These tools are often used to adjust specific components on trowel machines, such as blade angle or tilt.

Assessing Blade Alignment

Inspecting the existing blade alignment

- Start by visually inspecting the current alignment of the trowel machine blades.

- Look for any visible signs of misalignment, such as blades that appear uneven or at different heights.

- Pay attention to any wobbling or vibrations during operation, as these can indicate misalignment issues.

Identifying any misalignment issues

- Use a measuring tape, ruler, or level to assess the alignment of the blades more accurately.

- Measure the distance between each blade and the surface being troweled, checking for consistency.

- Look for any deviations or discrepancies in the measurements that indicate misalignment.

Importance of addressing misalignment promptly

- Misaligned blades can result in an uneven concrete finish, compromising the quality and aesthetics of the surface.

- It can lead to excessive wear on certain areas of the blades, reducing their effectiveness and lifespan.

- Uneven pressure distribution on the blades can strain the trowel machine’s components and may cause premature damage or failure.

Adjusting the Blades

Step-by-step instructions for adjusting blade angle

- Ensure the trowel machine is completely powered off and disconnected from any power source.

- This step is crucial for safety during the adjustment process.

- Locate the blade adjusting bolts or nuts that secure the blades to the trowel machine arms.

- Use the appropriate tool, such as an adjustable wrench or Allen wrench, to loosen these fasteners.

- Loosen them just enough to allow for adjustment but keep them secure enough to prevent from moving freely.

- With the bolts or nuts loosened, carefully adjust the pitch angle of the blades.

- Follow the manufacturer’s guidelines or your specific machine’s manual to determine the desired pitch angle.

- Adjust the blades evenly and symmetrically to maintain balance and consistency.

- Once the blades are adjusted to the desired pitch angle, re-tighten the blade adjusting bolts or nuts.

Step-by-step instructions for adjusting blade height

- As with adjusting the blade angle, ensure the trowel machine is completely turned off and disconnected from any power source.

- Locate the blade adjusting bolts or nuts responsible for adjusting the blade height.

- Use the appropriate tool to loosen these fasteners, allowing for vertical movement of the blades.

- Loosen them enough to facilitate blade height adjustment but keep them secure enough to prevent accidental movement.

- Carefully adjust the blade height according to the desired level for the concrete surface.

- Utilize a measuring tape, ruler, or level to ensure consistency across all blades.

- Make adjustments evenly to maintain uniformity in the concrete finish.

- After adjusting the blade height, re-tighten the blade adjusting bolts or nuts.

Testing the Blade Adjustment

Explanation of the importance of testing the adjustment

- Testing the blade adjustment is crucial to ensure that the adjustments made have resulted in the desired performance and surface finish.

- It allows you to identify any remaining issues or inconsistencies that need to be addressed before proceeding with concrete finishing.

- Testing ensures that the trowel machine is operating optimally, maximizing efficiency and achieving high-quality results.

Step-by-step instructions for conducting a test

- Start by turning on the trowel machine, following the manufacturer’s instructions for proper startup.

- Allow the machine to run at a low speed initially, gradually increasing the speed as needed.

- Observe the performance of the blades as they come into contact with the concrete surface.

- Pay attention to the evenness of the finish, smoothness, and any signs of blade chatter or excessive vibration.

- Look for any areas of the surface that appear uneven or require further attention.

- If you notice any issues or inconsistencies during the test, stop the machine and make further adjustments.

Maintenance Tips

Regular inspection and cleaning of the blades

- Conduct regular inspections of the trowel machine blades to identify any signs of wear, damage, or buildup.

- Remove any debris, concrete residue, or other substances that may accumulate on the blades.

- Use a wire brush or a suitable cleaning solution to clean the blades thoroughly.

- Regular cleaning helps maintain optimal blade performance and prevents the accumulation of materials that could affect the quality of the concrete finish.

Importance of replacing worn or damaged blades

- Monitor the condition of the trowel machine blades and promptly replace any blades that are worn and damaged.

- Worn or damaged blades can lead to uneven finishes, reduced efficiency, and increased stress on the machine.

- Follow the manufacturer’s guidelines or recommendations for blade replacement intervals based on usage.

- Using sharp and properly maintained blades ensures consistent results, prolongs the life of the trowel machine, and enhances the overall quality of concrete finishing.

Conclusions

In conclusion, properly adjusting trowel machine blades is crucial for achieving a smooth and even concrete finish. By understanding the significance of blade angle and height adjustments, civil engineers can optimize the performance of trowel machines and enhance their concrete finishing capabilities.

Regular maintenance, including inspection, cleaning, and timely blade replacement, is essential for ensuring long-term equipment durability and delivering high-quality results. Remember to prioritize safety by following proper procedures and wearing appropriate personal protective equipment.

As you continue to hone your skills in adjusting trowel machine blades, strive for precision and stay updated with manufacturer guidelines and industry best practices. With diligence and attention to detail, you can master this aspect of civil engineering and produce outstanding concrete finishes.

Sources:

Leave A Comment