Trowel Machine: How It Works, How To Use

Concrete finishing is an important step in concrete laying and paving. Finishing concrete involves leveling, smoothing, compacting, and otherwise treating the surface of fresh concrete or recently placed concrete to achieve the desired results. There are various types of concrete finishing equipment available.

In this article, we will be discussing a very common equipment name as a trowel machine. The article will discuss its functioning, types, and working mechanism.

Contents

Trowel Machine

Trowel machine, also known as power floats, are tools used during construction to apply a smooth finish to concrete slabs. It is essential to trowel after each concrete pour because this allows the concrete to continue the process of finishing the concrete and squeezing out residual water. The concrete is less likely to crack if excess water is removed from it.

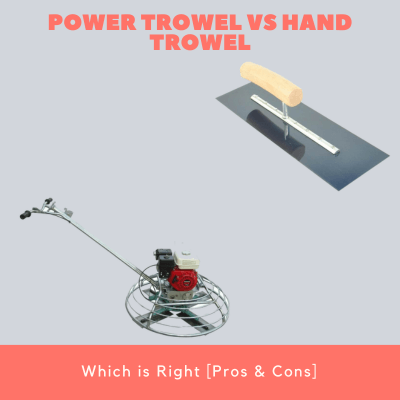

There are two types of trowel machines:

The working mechanism of these two types of trowel machines is essentially the same. The only difference is how they are operated. In the case of ride-on trowel machine, as the name depicts, it is operated by riding atop of it. The troweling blade is installed below the operator’s chair.

While in the case of the walk-behind trowel, the operator walks behind the troweling blade and steers it by applying force through the hands. Both of these types can be powered through either gas engines or electric motors.

What Is the Working Mechanism

Ride-on trowel machine

The ride-on trowel machine is only cost-effective when finishing large concrete floors. Since operators sit on the machines, they save both time and labor. Due to their steering systems, ride-on trowels are easy to control. As they do not require a lot of effort to operate, operators can be more efficient.

It is much easier to operate a ride-on trowel machine than a walk-behind machine. The market has been flooded with power-assisted models with hydraulic and electronic steering thanks to innovation and development. New models include advanced features such as torque converters and variable speed clutches.

They are used on floors, terraces, and concrete roads for their superior finish. In addition to being heavier, more expensive, and difficult to transport, they can also be quite expensive. Because it is easier to spot flaws on the finished surface using walk-behind trowels, some operators prefer walk-behind machines over ride-on models. The operator’s focus is on driving rather than the finished surface, so defects in the finish have to be corrected on the next pass

Walk-behind trowel machine

Trowels that walk behind are ideal for places where a ride-on model cannot be used, such as around protrusions and near the edge of a surface.

As a result, they require less maintenance and are easier to transport because they are lighter. The lighter weight also allows finishers to get onto the concrete surface more quickly than if they were using heavier ride-on machines. The manual models are preferred by some finishers since they believe they allow them to observe the surface better.

Walk-behind trowel machines require a lot of strength to push, which makes them more difficult to operate, as well as more time to complete. In this case, though, the operator can see how the concrete is being finished and can correct any mistakes immediately. The machines are cheaper than others, but they still produce the same quality of finish. Additionally, a walk-behind model’s engine is much smaller since only one rotor needs to be powered. A walk-behind machine isn’t just a simple machine; it’s a machine with a lot of features, such as enclosed gearboxes and vibration-dampening handles.

How To Use

Checks before using the trowel machine

Following checks should be made before starting any type of trowel;

- Engine oil level

- The level of hydraulic oil in the pump

- Fuel tank level

- Tank water level

- The condition of the air filter

- The condition of the arm and blade of the trowel

- Check to see if daily maintenance has been performed on grease points

Leaks should be checked on all fittings and hoses

Ride-on trowel machine

- Ensure the operator is seated in a position that is comfortable for him or her.

- Turn on the engine and hold the key switch until the engine starts.

- If the engine is cold, pull out the choke control knob completely. Even a warm engine may need a choke opened. Over 5 seconds of cranking the engine can damage the starter. Release the key and wait for 10 seconds before starting the engine again if the engine fails to start.

- Before operating the trowel, let the engine warm-up.

- Start the trowel by pressing the throttle pedal firmly

- To utilize your Ride-On Trowel to its fullest potential, it should be driven in the direction in which the operator is facing. This allows the operator to see the slab surface being troweled as clearly as possible while finishing the largest area possible. The machine needs to make a 180°U-turn when it reaches the end of the slab, then continue straight.

- Ride-on trowel speed can be controlled by “feathering” the left joystick forward and backward while controlling the right joystick.

Walk-behind trowel machine

- As soon as the engine of the trowel machine is started, the blades can now be spun.

- You can increase the speed by adjusting the throttle control on the handle. The blades should now start spinning on the floor. By adjusting the throttle control, you can change the speed of the blades.

- The blades of the trowel should now be moving, so you can get a feel for the trowel’s steering. By pressing down on the handle of the unit, you can move it to the right. The trowel should be gently moved to the right after this. Lightly lift the handle of the trowel if you want to move it to the left. This is how a trowel is used. After operating it more often, you will be able to gauge how much pressure you need to steer the device.

- How you operate a trowel varies according to the type of surface. You might need to get used to it on wet concrete before feeling comfortable on hard concrete. The feeling of working with dry concrete is very different than working with wet concrete.

Conclusions

To conclude, in this article we discussed two types of trowel machines, which differ from each other in terms of their steering mechanism. Ride-on trowel machines are steered using the engine power while walk-behind trowel machines are steered by pushing them with hands.

With ride-on trowel machines, large areas can be finished quickly but it is difficult to keep a check on the quality of finishing due to limited visibility. In the case of ride trowel machines, quality can be maintained but they are a bit laborious to use for larger areas. So it all depends on you, which type you want for your project. Both types have easy functioning and can be powered through either gas engines or electric motors. The product cost may vary from manufacturer to manufacturer.

Leave A Comment