Manual Rebar Bending Machine: Simple, Versatile, and Effective

Rebar bending machines are used in multiple industries, primarily where construction is carried out; hence, the industry is highly dependent on these machines. These machines are used for bending the steel and other metal bars to shape them and allow them to be converted into a usable state.

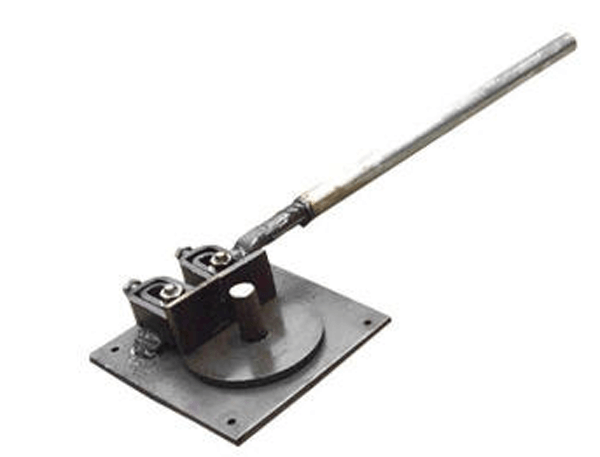

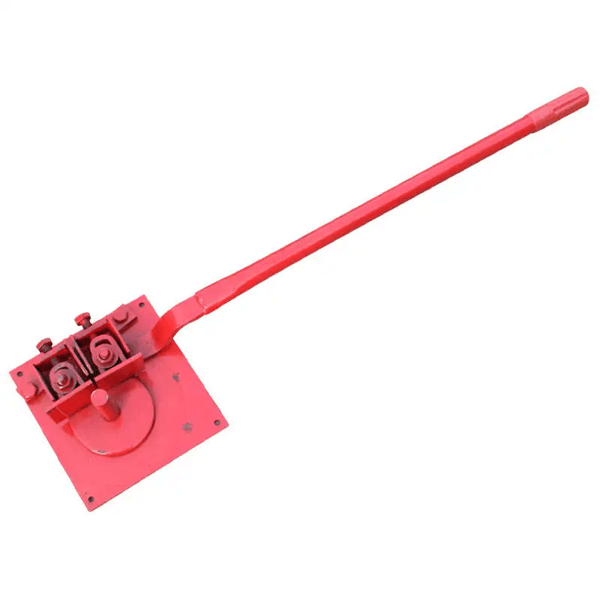

There are many kinds of rebar bending machines, some automated and some manual. The manual rebar bending machine is a simple bending tool that is easy to operate and has been used in the construction industry for many years.

The concrete construction industry still uses manual bending machines for many reasons. Pushing the lever in it and applying strength, the materials may be bent down and converted into a usable state.

Despite the electronic machines being floated these days, manual ones are also used widely for simplicity. They are straightforward to work with; hence, labor finds them suitable for bending metal rods and bars to create angles.

Contents

What Are the Advantages

The changing times have brought multiple innovations in the machinery used for different purposes, and the same is for bending machines. The manual rebar bending machine offers many benefits, and some of the common ones are:

Easy to Use

The manual rebar bending machine is straightforward to use. It doesn’t have any technical buttons and programming that is out of question for a laborer who is new to using it.

It has essential components and a straightforward method for bending the bars and rods. Once the labor has gained skill, he can do it very quickly.

Affordable Solution

Electronic and portable rebar bending machines are also floated in the market these days, but one of these machines’ most critical aspects is their cost.

Every construction project has a fixed budget, these machines can be bought or invested in quickly. The projects where the budget is tight, manual machines are required to control expenses.

Therefore, the manual rebar bending machine is one of the most affordable options to invest in because it won’t cost much and, with some added effort, will help achieve the optimal results of bending the metal bars.

Caters Many Projects

A manual rebar bending machine cannot just create a particular style or design of steel angles. It can create and bend multiple forms of bars that are suitable for many projects

In an automated rebar bending machine, the control depends on the precision offered by the machine, which sometimes limits the accuracy you might be looking forward to. However, when using a manual machine, the precision depends on your eye; hence, there are no limits.

Therefore this process offers a high level of versatility which is suitable for all the projects and hence is capable of carrying multiple projects based on many dimensions.

The Components

There are many components of a manual rebar bending machine, and some of these components include the following:

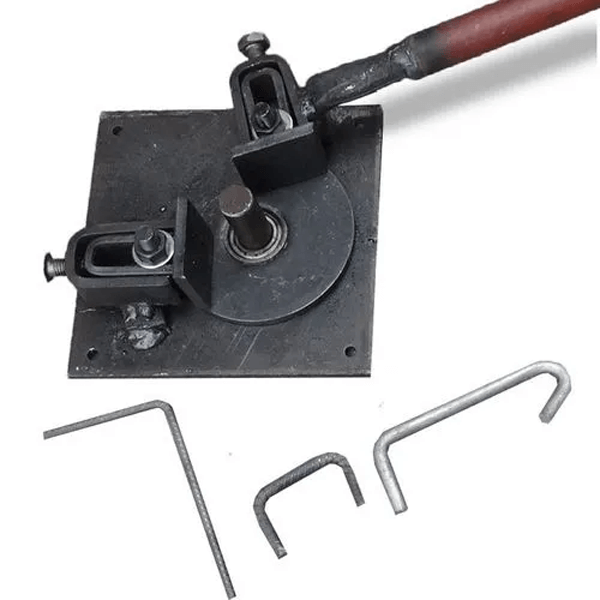

Bend Die

The first component is the bend die, also known as the radius die, and is an essential part of the machine. It contains a tube that allows the bending of the metal, so choosing this die carefully is very important.

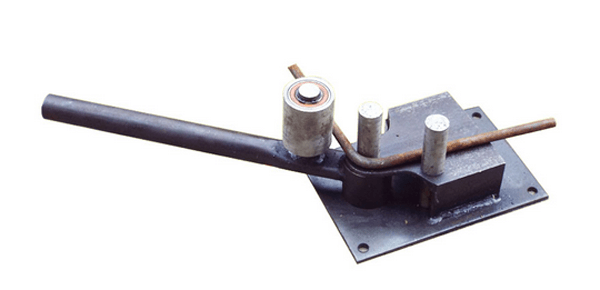

Clamp Die

The clamp die is a clamp that leads to a pressing tube on the bend die, and it holds the pipe or the bar from slipping away and tightly secures it.

Pressure Die

The pressure die, as the name suggests, is a component that adds pressure on the object or rod that has to be bent and formed into something. The role of the pressure die is to ensure that the force is maintained to turn the bar against the bend die.

Wiper Die

The wiper die comes at the back of the bend die, and it ensures that there are no humps formed in the inner radius.

The process of forming might cause wrinkles to form along the materials subjected to bending; it happens when there are large deformations. However, by adding a wiper die, the wrinkles may be avoided, and hence a smooth surface is obtained.

Mandrel

Mandrel is used in bending aluminum or steel tubes, carrying out the problematic bending task. When tubes of a smaller radius or a thinner size are bent, there is a risk of having an outcome that is not satisfactory enough. In this case, the mandrel helps to be a perfect choice, protecting the tube against collapsing.

How to Use a Manual Rebar Bending Machine

The process of using a manual rebar bending machine comprises the following steps.

- The very first step requires setting the rebar on the bar bender. The bar bender contains the lever and a bending plate through which the worker may easily adjust the angle of the rebar.

- There must be a mark on the rebar where it has to be bent so that the worker knows to which point the rebar needs to be bent.

- The next stage is securing the rebar; for this, a clamp on the manual bar must be used to hold the rebar from slipping tightly.

- The lever must be pushed until it has reached the mark and done with force; however, care should be taken to prevent the rebar from breaking.

- Once the rebar has bent, the lever must return to its position, and the clamp should be loaded.

- The rebar must now be checked to see if it has bent correctly and achieved the desired angle. If there is room for more bending, the entire process should be repeated to allow the bending to continue until the required position.

When using this manual rebar bending machine, exercise caution and avoid keeping your hands on the rotation areas or clamps, as this could cause an injury.

Maintenance and Care

To ensure long-term usage of the manual rebar machine, it must be maintained and taken care of properly. The device’s moving parts must be lubricated timely so that they do not end up freezing in time of need.

Moreover, any grease or dirt must immediately be cleaned, and it should be stored where there is no moisture or sunlight, as that could cause the machine to rust or wear out quickly.

Conclusion

Many bending machines are taking the lead these days, but at the same time, they are expensive and need trained and experienced professionals to operate them.

However, choosing a manual rebar bending machine could be a better approach for small-scale projects because they do not require much investment and are easier to operate.

Leave A Comment