Bending Rebar: Can You Heat It? Pros-Cons, Safety Tips

Rebar, short for reinforcing bar, is a steel bar used as reinforcement in concrete structures. Rebar is available in various sizes and grades, and its primary purpose is to increase the structural integrity and strength of concrete by withstanding tension and compression forces.

It’s important to note that heating rebar is generally not recommended or practiced in construction. Rebar is typically cold-bent using manual or machine-assisted methods, as heating the steel can compromise its structural properties. Heating can lead to the loss of strength and ductility in the rebar, which are critical for its performance as reinforcement in concrete structures.

Therefore, it is best to rely on approved cold-bending methods and tools to shape and bend rebar accurately and safely. Read more to get better insight into bending of rebars.

Contents

Understanding Rebar

A. Definition and Composition of Rebar

Rebar, short for reinforcing bar, is a steel bar or rod used as a reinforcement material in reinforced concrete structures. It is made of carbon steel and is typically manufactured with deformations, such as ridges or ribs, along its surface. These deformations enhance the bond between the rebar and the surrounding concrete, ensuring better load transfer and improving the overall strength of the structure.

B. Common Uses of Rebar in Construction

Rebar is widely used in construction to reinforce concrete structures and enhance their strength and durability. Some common applications of rebar include:

- Foundations: Rebar is extensively used in concrete footings and foundation walls to provide stability and support the weight of the structure.

- Columns and Beams: Rebar is placed in concrete columns and beams to reinforce them, enabling them to withstand heavy loads and prevent structural failure.

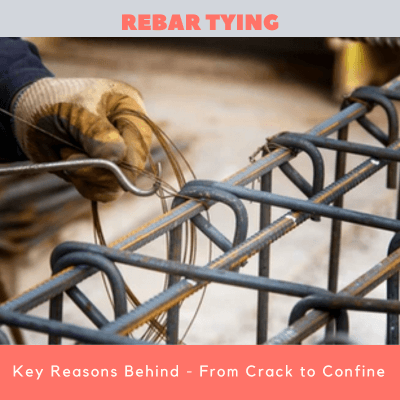

- Slabs and Floors: Rebar is embedded within concrete slabs and floors to resist cracking, increase their load-bearing capacity, and improve their resistance to bending and shear forces.

- Retaining Walls: Rebar is used in retaining walls to strengthen the structure and prevent soil movement or collapse.

- Bridges and Infrastructure: Rebar is an essential component in the construction of bridges, highways, tunnels, and other infrastructure projects, where it reinforces the concrete to withstand the forces and stresses imposed by heavy traffic and environmental conditions.

C. Importance of Bending Rebar to Achieve Desired Shapes

Bending rebar is crucial in construction as it allows the reinforcement to be shaped to match the specific design requirements of the structure. The importance of bending rebar includes:

Structural Integrity: Bending rebar enables it to be placed in the desired configuration within the concrete structure. This helps in reinforcing critical areas such as corners, intersections, and curved elements, ensuring the structural integrity of the construction.

Load Distribution: By bending rebar, it can be positioned and distributed strategically within the concrete to evenly distribute the load across the structure, minimizing stress concentrations and improving the overall load-bearing capacity.

Flexibility in Design: Bending rebar allows for greater design flexibility, as it can be shaped to meet various architectural and engineering requirements. This enables the construction of unique and intricate structures while maintaining the necessary strength and stability.

Heat and Its Effects on Rebar

A. Explanation of the Behavior of Steel Under Heat

Steel, the primary material used in rebar, undergoes certain changes when exposed to heat. As the temperature rises, steel expands due to thermal expansion. This expansion occurs uniformly until it reaches a specific temperature known as the critical temperature or recalescence temperature.

If the temperature continues to rise beyond the critical temperature, the steel may start to lose its load-bearing capacity and undergo further structural changes. Excessive heat can lead to the loss of strength and structural integrity of the steel.

B. Effects of High Temperatures on Rebar Properties

Exposing rebar to high temperatures can have several detrimental effects on its properties, including:

- Loss of Strength: High temperatures cause rebar to lose its strength and load-bearing capacity. This can compromise the structural integrity of reinforced concrete elements, leading to potential failures.

- Reduction in Ductility: Ductility refers to the ability of a material to deform under stress without fracturing. High temperatures can reduce the ductility of rebar, making it more susceptible to brittle fracture.

- Reduction in Bond Strength: The bond between rebar and concrete is crucial for transferring loads effectively. Elevated temperatures can weaken this bond, reducing the overall performance of the reinforced concrete structure.

- Dimensional Changes: Steel expands when heated, and this expansion can lead to dimensional changes in the rebar, affecting the accuracy of the reinforced concrete element.

C. Considerations for Heating Rebar Safely

Heating rebar for bending purposes is generally not recommended due to the potential negative effects on its properties. However, if heating is necessary, certain precautions should be followed to ensure safety:

- Temperature Limit: Heating should be limited to a controlled and moderate temperature below the critical temperature of the steel. This helps minimize the adverse effects on the rebar’s properties.

- Heating Technique: Induction heating is often considered a safer method for heating rebar, as it allows for localized heating without subjecting the entire length of the rebar to high temperatures.

- Uniform Heating: If heating is required, ensure that the heat is applied uniformly to avoid localized hot spots that could lead to uneven thermal effects and potential damage to the rebar.

- Quenching: After heating, it is recommended to cool the rebar rapidly, using methods like water quenching, to minimize the time the steel spends at elevated temperatures and mitigate potential property changes.

Heating Techniques

A. Traditional Methods of Heating Rebar

Traditionally, rebar was heated using open flame methods, such as oxyacetylene torches or gas flames. The rebar was exposed to the flame until it reached the desired temperature for bending.

B. Modern Approaches for Heating Rebar

Modern heating techniques have evolved to provide more controlled and efficient heating processes for rebar. Some common modern approaches include Induction Heating and Electric Resistance Heating

C. Advantages and Disadvantages of Different Heating Techniques

Traditional Methods (Open Flame):

Advantages: Relatively low cost, widely available equipment.

Disadvantages: Difficult to control the temperature accurately, uneven heating, potential for overheating and damaging rebar properties, safety hazards.

Induction Heating:

Advantages: Precise and localized heating, uniform temperature distribution, controlled heating process, reduced risk of overheating and property damage, faster heating times, safer operation.

Disadvantages: Higher initial cost for equipment compared to traditional methods.

Electric Resistance Heating:

Advantages: Controlled and uniform heating, flexibility in heating configurations, suitable for smaller-scale applications.

Disadvantages: Limited to smaller-scale heating requirements, longer heating times compared to induction heating, may require special equipment and setup.

Safety Precautions

Safety is of utmost importance when working with heated rebar. Heating rebar can introduce additional hazards and risks due to the high temperatures involved. It is essential to prioritize safety to prevent accidents, injuries, and damage to property. By implementing proper safety measures, construction workers can mitigate potential risks and ensure a safe working environment. To prevent accidents or injuries when working with heated rebar, the following protective measures should be implemented:

- Personal Protective Equipment (PPE): Wear appropriate PPE, including heat-resistant gloves, safety glasses or goggles, and flame-resistant clothing, to protect against burns, sparks, and flying debris.

- Fire Safety Precautions: Have fire extinguishers readily available and ensure workers are trained in their proper use. Clear the work area of flammable materials and establish fire safety protocols.

- Ensure there is proper ventilation in the work area to minimize the accumulation of heat, fumes, and gases.

Recommended Safety Equipment and Procedures

To ensure safety when working with heated rebar, the following safety equipment and procedures are recommended:

- Heat-Resistant Work Surfaces

- Heat-Resistant Shields

- Thermocouples and Temperature Monitoring

- Emergency Response Plan

- Regular Equipment Inspection

- Proper Storage and Handling of Heating Equipment

Best Practices for Heating and Bending Rebar

Heating and bending rebar require careful attention to ensure safety and achieve accurate results. Here are some best practices to consider when heating and bending rebar:

- Use Proper Heating Techniques

- Follow Manufacturer Guidelines

- Temperature Control

- Proper Bending Equipment

- Bend Gradually

- Cooling and Quenching

- Quality Control and Inspection

- Personal Protective Equipment (PPE)

- Training and Experience

Alternative Methods for Bending Rebar

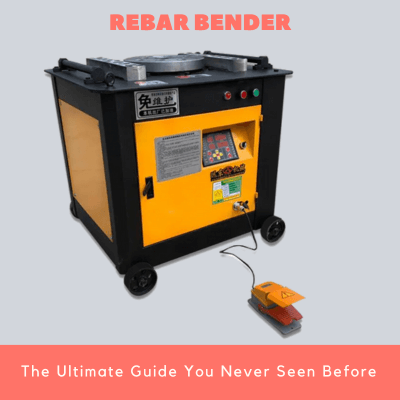

- Mechanical Rebar Benders: These machines use mechanical force to bend the rebar, offering a precise and efficient bending process. They can be manual or electric-powered.

- Hydraulic Rebar Benders: Hydraulic-powered machines provide high bending capacity and accurate bending angles. They are suitable for heavy-duty applications and can handle thicker rebars.

- Manual Bending Tools: Handheld tools like rebar benders, rebar hickey bars, or manual pipe benders can be used for bending rebar on a smaller scale or in situations where power tools are not available.

Conclusions

In conclusion, heating rebar can be an effective method for achieving perfect bends in construction projects. It offers increased flexibility, precision, and time efficiency compared to cold bending methods. However, it is important to consider the potential drawbacks and prioritize safety throughout the process.

Leave A Comment