Rebar to Concrete: Boosting the Construction Lifespan

Concrete and its significance in construction

Concrete is one of the world’s oldest and most common construction materials. It is known for its enduring strength and durability in harsh weather conditions.

Concrete is a mixture of fine aggregates, coarse aggregates, and cement. Over the years, the development of mix variations and additives has improved the strength of concrete. Where high strength is needed, concrete is reinforced using steel reinforcement bars (rebars).

Reinforcement bar (rebar) and its basic function

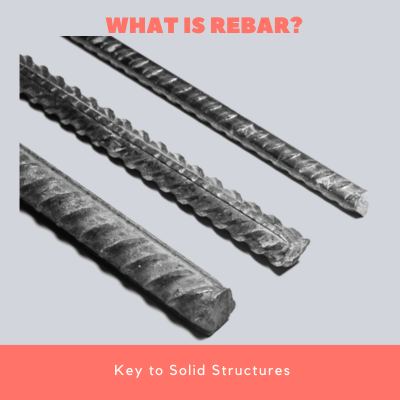

Reinforcement bars, also known as tendons are pieces of steel put inside concrete to improve its tensile and compressive strength. Rebar application depends on the nature of the concrete members being constructed. The number of bars and arrangement patterns depends on the structural design provided by professionals. Rebars are either twisted or ribbed; ribbed bars have a rough surface to enhance bonding with concrete.

Contents

The Science Behind Rebar

Tensile vs. compressive strength in materials

Construction materials are subjected to different forces depending on where they are applied. In structural members such as beams, columns, slabs, and foundations; tensile and compressive forces are most prevalent. When two forces acting in an opposite direction are applied to a material, they cause tension. When the forces act towards each other, they cause a compression effect on the material particles. The materials’ ability to withstand tension is known as tensile strength while resistance to compression is compressive strength.

Low concrete tensile strength compensation by rebar

Concrete structural members have two main points of action when loaded. Tensile forces act on the lower part of the middle axis while compressive forces act on the upper part. The axis is a line dividing the structural member into two parts horizontally.

For tensile strength, reinforcement bars are placed at a determined distance below the structural member’s axis; known as bottom bars. The rebars’ tensile strength combined with the concrete offers higher resistance to failure.

Tensile and compressive failure in materials

Materials fail in different forms when subjected to tension and compression forces. The physical appearance of a material when loaded can be used to tell whether it is failing due to compression or tensile forces.

Under tension, the material displays one or two cracks perpendicular to the axis. In concrete structural members, tensional failure is shown by cracks appearing at the bottom surface of the member.

Compression failure is displayed by a crushing effect on the material’s top surface. In horizontal structural members, failure under compression is shown by multiple cracks on the surface.

Enhancing Concrete’s Tensile Strength

How rebar absorbs and redistributes tension

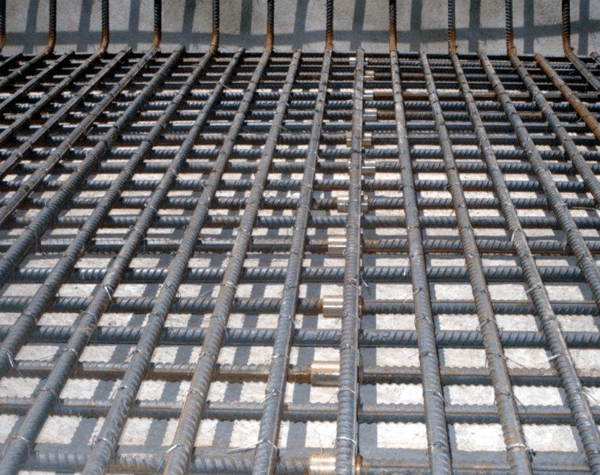

Both top and bottom rebars are arranged in two directions. The main bars and distribution bars. At the bottom, main bars (along the longer span) are responsible for absorbing the tension within a concrete structural member and transferring the load to supporting structural members.

Distribution bars run perpendicular to the main bars; they are responsible for distributing the load uniformly throughout the concrete structural member.

Reinforcement process during concrete setting

Concrete reinforcement starts from the structural design stage. Once concrete structural member sizes and reinforcement requirements have been established, a bar bending schedule is prepared.

The bar bending schedule is a list of bars, their sizes and lengths, form, and location to be placed in the structure. You should cut, bend, and place the rebars as directed in the bar bending schedule; tying each bar in place using steel binding wires.

Once the bars have been arranged, they should be spaced from the formwork as directed by the engineer. The space between the rebars and formwork will allow concrete to settle in and create a concrete cover.

Once the concrete cover space has been checked and approved to standards, concrete is then poured over the reinforcement and allowed to settle.

Concrete reinforcement design against cracking

Cracking in concrete; why is it a normal but controllable phenomenon

Cracking in reinforced concrete occurs for several reasons. The structural impact depends on the severity of the cracks. Besides structural failure in tension and compression, cracks in concrete are caused by shrinkage. After casting, concrete loses moisture, a process known as bleeding, the loss of moisture causes shrinkage. Other causes of concrete include swelling, which occurs due to the presence of impurities in concrete. Moisture-related shrinkage is referred to as hydraulic shrinkage while thermal shrinkage is due to temperature variations.

Proper water rationing in concrete mix design prevents hydraulic shrinkage and resultant cracks. Adding water to cast concrete; a process called curing, slows down moisture loss preventing cracking. Using impurity-free aggregates and water during mixing prevents swelling which might lead to cracking. The fire and heat resistance design of concrete members prevents thermal shrinkage.

Role of rebar in directing and minimizing the spread of cracks

Steel and concrete have close variations when subjected to temperature changes. Steel-reinforced concrete is more resistant to thermal shrinkage due to the conductivity of rebars.

Due to the high tensile strength of steel, rebars restrict the expansion of concrete when exposed to temperature increments; preventing cracks. Shrinkage in concrete is also prevented by the steel’s compressive strength eliminating cracking.

The concept of crack control joints and how they work in tandem with rebar

Concrete contraction and expansion lead to random cracking of the concrete structure. Crack control joints are lines of weakness created on concrete upon casting. These lines are strategically placed in zones that do not adversely affect the structural integrity of the concrete structure.

Upon shrinkage, the cast concrete cracks along the control joint. Rebars are laid across the control joint to prevent excessive cracking. Crack control joints should be limited to a maximum of 2.5 inches depending on the member thickness.

Environmental Stress Mitigated by Rebars

Thermal expansion and contraction in concrete structures

Concrete is a solid matter subject to temperature changes. When subjected to temperature increase, concrete increases in volume. Volume reduction is experienced when the concrete structure is subjected to low temperatures.

In extreme conditions, the expansion and contraction could be severe leading to cracking of the concrete members. Proper temperature resistance design for the structure conserves structural integrity and safety.

How rebar provides stability against environmental stresses

Rebars have good conductivity; they distribute heat uniformly throughout the reinforced concrete structure. This prevents structural damage due to localized extreme temperature variations.

Additionally, the tensile strength of rebars holds the concrete mass together limiting expansion and contraction. As a result, cracking is prevented.

Impact of temperature changes on concrete integrity and rebar’s role

Concrete settling and hardening is by hydrolysis; an exothermic reaction. Temperature changes can affect the hydrolysis process leading to insufficient concrete strength after the expected 28-day period. Solidi concrete expands and contracts depending on temperature changes.

In extreme conditions, the expansion and contraction could lead to cracking which compromises the structural integrity. Rebars hold the concrete mass together preventing expansion and contraction. The expansion forces are countered by the tensile strength of the rebar preventing cracking.

Steel Reinforcement Design for Different Applications

Deciding the type and spacing of rebar

The type and spacing of rebar are determined through structural design calculations. The rebar is chosen based on the design loads to be applied to the structural member. Design loads refer to the amount of weight from construction to the full utility of the structure.

Depending on location, other loads applicable include snow loads, wind loads, and seismic loads. Bottom reinforcement bars and spacing are selected to withstand sagging moments resulting from tensile forces. Top reinforcement bars are designed to withstand hogging moments caused by compressive forces.

Rebar grades and sizes for specific construction needs

Reinforcement bars exist in different sizes and grades. The selection depends on the structural design provided by an engineer. There are three main types of rebars; plain bars, twisted bars, and ribbed bars. Twisted and ribbed bars are commonly used in concrete reinforcement due to their ability to bond with concrete.

Rebar sizes vary from 6mm to as high as 40mm; the sizing and spacing depend on the structural loading being reinforced against. In light concrete structures, 6mm wide bars are used as reinforcement links. The minimal advisable size of main and distribution bars in concrete structures is 8mm; prevents vibration when the member is subjected to live loads.

How Does Reinforcement Contribute to The Longevity and Durability of Concrete Structures

Lifespan extension of concrete structures through reinforcement

Concrete structures fail over time due to continued load application; a process called structural fatigue. Reinforcement improves concrete strength and resistance to fatigue leading to increased service life.

Under extreme weather conditions, the expansion and contraction of concrete leads to cracking which lowers the structural integrity. Reinforcement limits the expansion and contraction preventing cracking; this improves durability and longevity.

Comparison of structures with and without rebar reinforcement

Unreinforced concrete is brittle; immediately breaks when design loads are exceeded. Reinforcement improves the elasticity of concrete slowing down failure in case design loads are exceeded.

As a result, more time is left for evacuation saving lives. Reinforcement improves concrete’s resistance to lateral forces such as earthquakes. Such unprecedented loads can cause massive damage to unreinforced concrete.

Long-term benefits of investing in reinforced concrete

Maintaining buildings is expensive; reinforced concrete minimizes cracks and other structural failures that might require often repairs.

Smoothened concrete surfaces are easy to clean and are resistant to corrosion when exposed to different environments. For this reason, aesthetics is easier to maintain compared to other structures.

Conclusions

Despite the popularity of concrete, it falls short of structural strength necessitating the use of reinforcement bars. Reinforcement bars used in concrete improve the general structural strength of concrete making it suitable for many applications. Thanks to its resistance to environmental factors; such as moisture and temperature changes, concrete is considered one of the most durable construction materials.

Reinforcement bars prevent excessive shrinkage and expansion of concrete due to temperature changes; this maintains the structural integrity of concrete buildings. In construction, using rebar eliminates the cost of regular repairs due to cracking saving you from unnecessary maintenance costs. With reinforced concrete, it is easier to maintain the aesthetics since it is easy to clean and resistant to corrosion.

Thanks to technological advancements, concrete is being improved for application in extreme weather conditions. Thanks to developed additives, concrete can now be used in saline conditions such as in under-sea structures. Additives have been developed for fast concrete construction; these include rapid hardening cement used in the construction and repair of critical infrastructure.

Leave A Comment