Why Rebar? Unveiling Its Crucial Role in Concrete

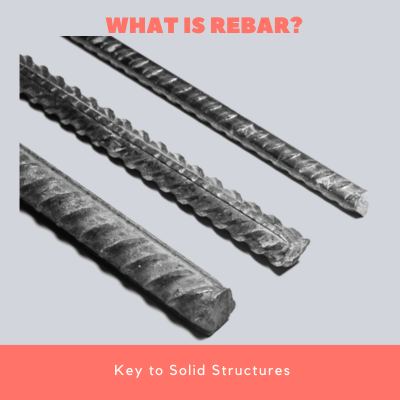

Reinforcement bars; commonly known as rebar are steel pieces incorporated in concrete to improve its structural strength.

Rebars exist in various sizes, shapes, and mechanical properties. However, round rebars are the most common in construction. Rebar classification is based on their diameter and mechanical properties. Round rebars with rough surface are known as ribbed bars.

An alternative to ribbed bars is twisted bars; also known as Y-bars. The twist and “ribs” on rebar provide for stronger bonding with concrete.

The Evolution of Rebar Usage in Construction

The French construction industry is considered pioneers of reinforced concrete construction. The idea of using bars made of steel or iron to improve the strength of concrete became popular in the mid-1800s.

Joseph Monier, a French constructor received his patent for reinforced construction in 1867. Other companies and individuals interested in this construction method improved rebar shapes, material, and arrangement for better performance.

Reinforced concrete technology spread through Europe and finally into the U.S in late 1800s. By the end of the first quarter of the 20th century, reinforced concrete was a popular and most preferred construction technique. The improved strength allowed construction of high-rise structures allowing economical land usage.

Early construction used twisted square rebars; however, the standards varied affecting the quality of construction. The American Society for Testing and materials formulated standards for use across rebar manufacturers in 1947.

The specifications have been adjusted with new development over the years thanks to research by the manufacturers. However, some standards such as deformed bar specifications are still applicable in construction to date.

Contents

The Science of Concrete and Rebar

Concrete in Compression: Strengths and Limitations

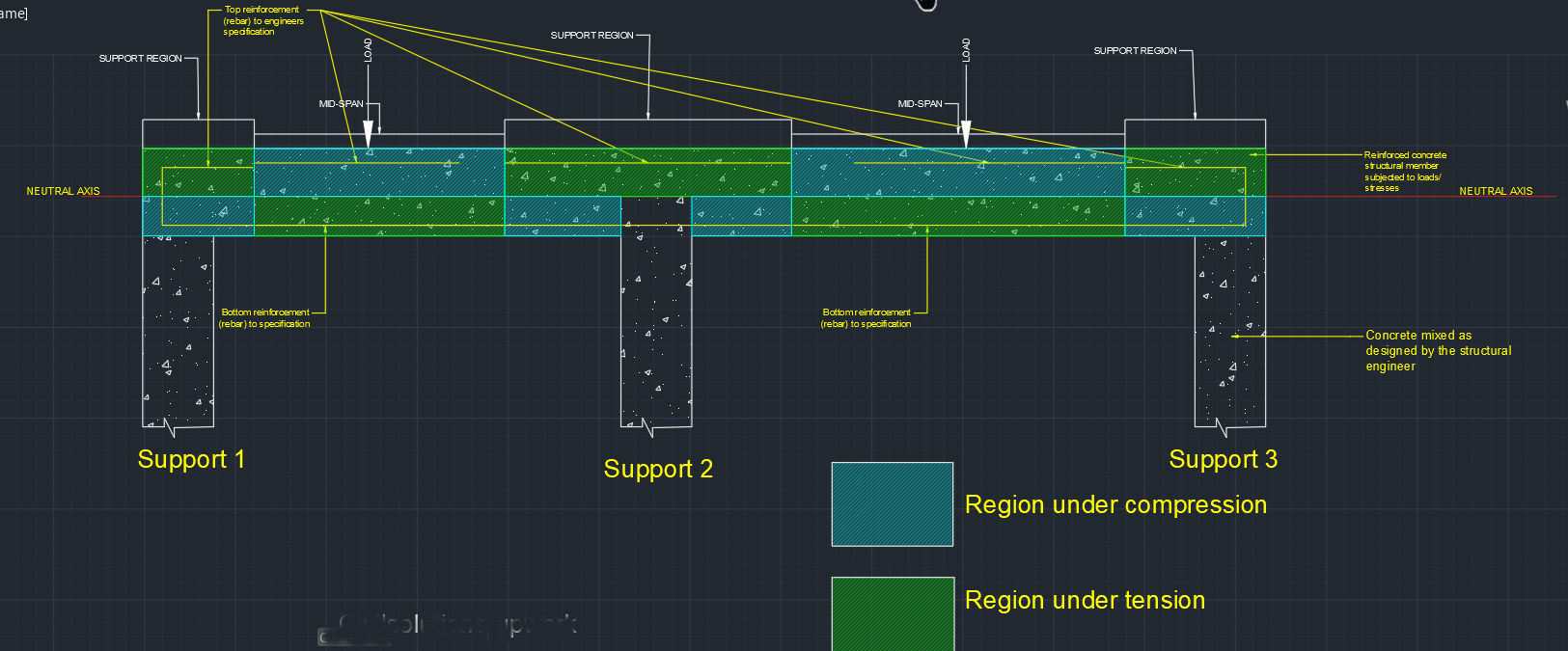

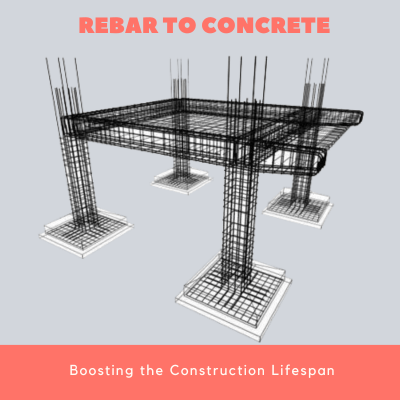

Reinforced concrete structural members are divide into three parts; two support regions and the mid-span, as shown in the diagram above.

When reinforcing against compression, it is important to know where compressive forces occur. Concrete has impressive resistance to compression; however, it might fail in extreme conditions.

In concrete members, compression occurs mid-span above the neutral axis. Below the neutral axis, compression occurs at the support region.

Why Concrete Needs Rebar: Tensile Strength Explained

Contrary to compressive strength, concrete has very low tensile strength. Tensile stresses refer to the pulling apart of concrete material when subjected to a load.

The figure above shows where tensile stresses act in a concrete structural member. Rebars have a higher tensile strength than concrete. The ribs on rebar hold cast concrete together preventing separation of particles.

Types of Rebar and Their Properties

Carbon Steel Rebar

Carbon steel is the most common type of rebar in the construction industry. Its popularity is due to its high yield strength and versatility.

Carbon steel rebar comes in two main classifications, these determine its application; A615 Grade 60 and A706 Weldable. Grade in the bar-naming criteria indicates the minimum yield strength; i.e. Grade 60 implies that the minimum yield strength of the bar is 60,000 pounds per square inch. Weldable bars are applicable in areas that require welding; or bar sizes that prove hard to hold together using binding wires.

Carbon steel rebars can be classified depending on carbon concentration in the steel used. The classification is as follows;

- Mild carbon steel rebar- Contains up to 0.3% carbon

- Medium carbon steel rebar- Contains 0.3% to 0.6% carbon

- High carbon steel rebar- Contains 0.6% to 1.0% carbon

- Ultra-high carbon steel rebar- Contains more than 1% carbon.

Stainless Steel Rebar

Stainless steel bars are corrosion resistant; however, they are more expensive compared to galvanized rebar. Stainless steel rebars are used in areas that are susceptible to corrosion but zinc isn’t allowed.

They provide an eco-friendly form of concrete reinforcement.

Galvanized Rebar

For reinforcement in corrosion-prone areas, galvanized rebars are the best. These are steel bars coated with zinc through an electro-chemical reaction; galvanization.

Galvanized rebars are commonly used in saline environments; such as in marine construction.

Epoxy-Coated Rebar

Epoxy coating provides an economical protection against corrosion. Epoxy-coated rebar are usually carbon steel bars with an epoxy coating on the surface. Despite the benefit, the surface coating is light and could break when exposed to concrete loads or shifting.

As a result, epoxy-coated rebars are applicable for light-weight concrete structures.

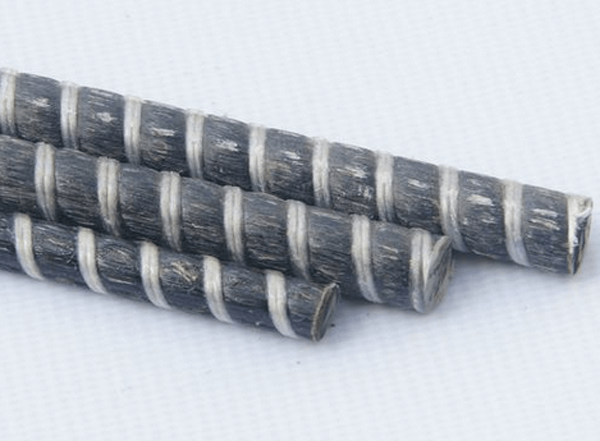

Composite Rebars

Composite rebars have been developed to address shortcomings of steel reinforcement in concrete construction. The rebars involve carbon fiber reinforced plastic (CFRP) blended with other materials in a polymer matrix to form bars. These bars are lightweight and resistant to corrosion; these reduces the concrete member self-weight; thus, less reinforcement is needed.

Composite bars have up to twice as much tensile strength as steel bars making them ideal for large scale projects.

Rebar Design and Engineering Principles

Understanding Stresses

Compressive stresses– From the name, compressive stresses occur when material is forced towards each other. Compressive stresses in concrete structures occur at mid-spans above the neutral axis and near supports below the neutral axis (As shown in figure above). Compressive strength is the resistance to compressive stress; in the case of failure, it is noticeable by several short cracks.

Shear stresses– Shear stresses occur when material slides passed each other along an axis (shearing). In concrete structures, shear failure is characterized by 45-degree cracks along the vertical face.

Tensile Stress– Tensile stresses (tension) occurs when material particles pull away from each other. (as shown in figure above).

Placement Strategies

Rebar positioning is determined by structural design and reinforcement detailing provided by the engineers. Although the positioning might vary from project to project, it is advisable to minimize cutting as it leads to wastage.

Unless confirmed otherwise by the structural design, compression forces determine which bars to place. Concrete has high compressive strength; thus, compressive reinforcement is usually lesser than tensile reinforcement. Understanding where forces act helps in optimal positioning of rebars.

Sizing and Grading

Reinforcement sizing governed by concrete structural design codes and standards. These standards vary depending on the region; UK uses EuroCodes and America uses ACI codes. The design codes outline the bar grade and size to use depending on building type, environmental conditions, and other factors.

Due to localization, some states within the US have additional guidelines on selection of rebar besides the national code.

Applications of Rebar in Construction

Reinforcement in Slabs, Walls, and Foundations

Reinforcement principles vary depending on the concrete structure being constructed. At a commercial construction site in Dallas, TX, two types of slab reinforcement were used. For the slab-on-grade, a 6mm thick BRC Mesh was used. The engineer advised that 12mm and 10mm ribbed bars be used for bottom and top reinforcement respectively in suspended slabs.

At the same site, a shear wall was needed for the elevator shaft. 20mm ribbed bars spaced at 6” from each other were used for the front and back sides of the wall. These provided sufficient additional strength for the wall to support the lift.

The reinforcement at pad foundations varied depending on the column loads. Those near the retaining wall had lesser reinforcement sizes since the shear wall supported part of the structural design load. The minimum bar size used for foundations was 10mm.

Special Considerations for Load-Bearing Structures

Load bearing structures undergo shortening and fatigue over time. When reinforcing, the amount of shortening is considered to prevent collapsing. Other considerations include proper concrete mixing for sufficient strength. Concrete is responsible for shear resistance, when the mix design is wrong, the structure might fail even with the right rebars.

Installation Techniques and Best Practices

Cutting, Bending, and Tying Rebar

For effective reinforcement, rebars need to be cut and bent as per the provided bar bending schedule. The bar bending schedule is a list of bar sizes, bent geometry, number, and spacing from each other.

As a builder, you need to have high attention to detail to avoid wrongful bending and placing of bars. Other basic skills include handling measuring and cutting equipment such as tape measures and saws.

Concrete Cover

Concrete cover is the amount of concrete between the outermost part of the rebar and the exterior surface of the concrete member. Concrete cover selection is guided by structural design codes; it varies depending on building location, usage, and anticipated service life.

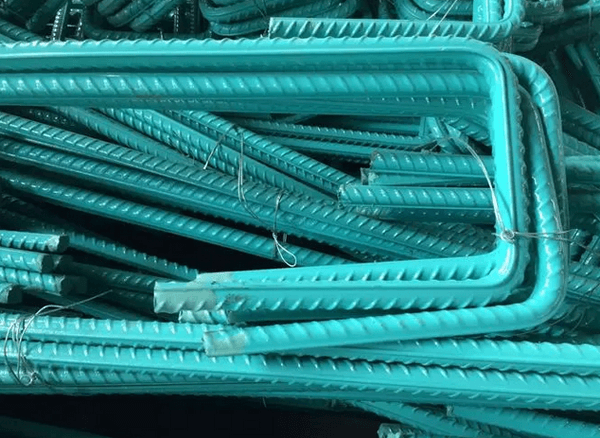

Advanced Techniques

Pre-bent rebars are measured, cut, and bent at the factory then brought to the site for placement and concrete casting.

Using pre-bent rebars prevents wastage and saves time that would otherwise be spent bending the bars on site. Modular construction, also known as pre-fabrication is where concrete structures are made in factories as designed then assembled at a site.

Modular construction guarantees quality since the conditions are controlled for perfection.

Alternatives to Traditional Rebar

Fiber-Reinforced Concrete

Fiber-reinforced concrete is made up of aggregates and uniformly distributed fibers to improve structural strength. The fibers are randomly oriented and could be steel, glass, or other synthetic material.

Fiber-reinforced concrete is good resistance to cracking. However, it is not as strong as rebar-reinforced concrete making it unsuitable for heavy construction.

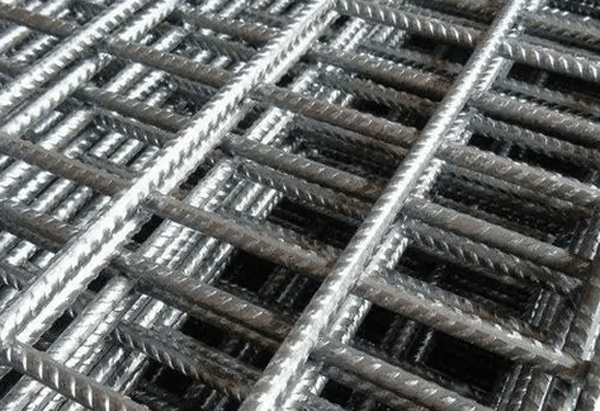

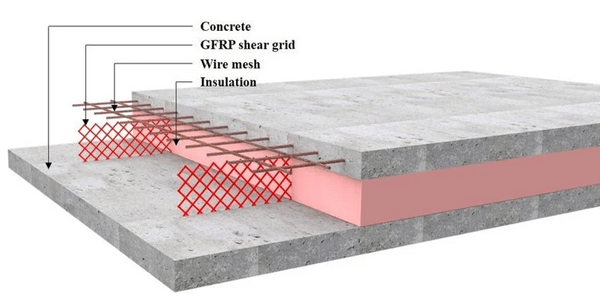

Using Wire Mesh Reinforcement

Wire Mesh a common reinforcement method in on-grade construction. Wire-mesh is used on ground construction due to its low tensile strength. In such construction, the structural load is directly transferred to the ground through compacted sub-layers, unlike in suspended members that transfer loads to supports.

Regulatory and Compliance Issues

Building Codes and Standards Related to Use

There are various codes and standards that govern the use of concrete and reinforcement bars. These codes vary depending on the country; some countries, especially developing countries adopt either the American or European standards. Popular codes are as follows;

- ACI 318-19- Reinforced Concrete Design for American Standard

- EUROCODE 2 (EN1992)- European Standard for Concrete Design.

- CSA A23.3- Canadia Reinforced Concrete Design Standard

Environmental Considerations

Environmental conservation is important in construction. Being a carbon-emitting process, rebar production contributes to potential global warming.

To minimize the adverse environmental impacts, manufacturers are using recycled steel to manufacture rebar. The recycled steel is prepared at factory level to attained the needed strength levels.

Troubleshooting and Maintenance

Common Issues with Reinforced Concrete

Reinforced concrete is a durable construction material. However, it may develop defects over time as its design service period approaches an end.

One of the common issues with reinforced concrete is cracking. Not all cracking in reinforced concrete is a call for alarm; cracks exceeding 5mm deep could be an indication of structural failure and should be addressed.

Cracking in concrete can be addressed by concrete injection. This is filling the crack with fresh concrete through a special gun or syringe. Non-destructive tests such as ferro scanning and Schmidt hammer test can be used to check the concrete reinforcement, cover, and compressive strength. These tests help determine the cause of cracks.

Maintenance Tips to Extend the Life of Reinforced Structures

Concrete tends to fail when exposed to adverse weather over a long time if its not designed to exist in such environments.

Cleaning the concrete of debris prevents growth of plants such as moss and accumulation of water. Debris create an additional load on concrete; speeding up its fatigue.

Water tends to sip through concrete. Excess moisture content lowers the tensile and compressive strength of concrete leading to structural failure.

Conclusions

To match concrete’s compressive strength and tensile strength, reinforcement is needed. While there are other forms of reinforcement, rebars are the most popular due to their versatility and ease of installation.

Reinforced concrete developed from the mid-1800s in France to become the worlds most popular building material. Thanks to advancements in technology, reinforced concrete led to introduction of high-rise structures which improved land use.

Despite its durability and strength, reinforced concrete could fail if not cast and maintained properly. Following the building codes and observing proper maintenance steps increases the lifespan of concrete while maintaining its structural integrity.

The development of composite rebars will revolutionize the use of reinforced concrete in construction. Being lighter and eco-friendly, many constructors will adopt it as the best option for minimal construction cost.

Light to medium scale constructions will embrace fiber-reinforced concrete. Due to technicalities in on-site concrete casting in future, many people will opt for factory bent bars and modular construction.

Leave A Comment