How to Power Trowel Concrete Like a Pro

Getting a smooth and durable finish on concrete isn’t just about pouring it right. The finishing step matters just as much. That’s where power troweling comes in.

For this purpose, a power trowel is used to smooth fresh concrete. This equipment makes it into strong and shiny finishes.

Warehouses, parking garages, and other like areas are common places to carry out power troweling. Having a power trowel can greatly affect your work if you are in construction.

This guide will show you how, step by step, using pro tips and tested techniques.

Contents

What Is Power Troweling

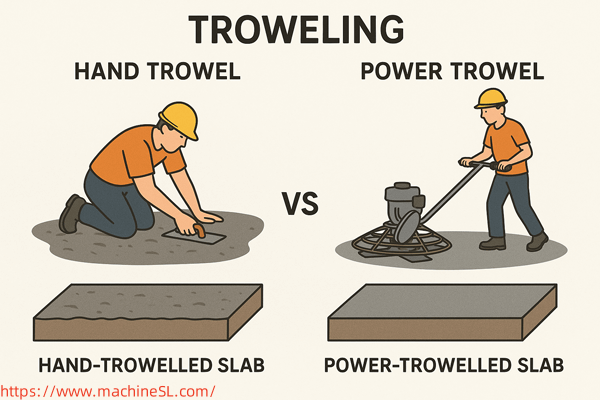

For going deep into “how”, let’s explore “what” first. Power trowelling is the process of making concrete smooth and even. It takes away the tiresome manual job of using a hand trowel.

It replaces the time-consuming work of hand troweling. Instead of kneeling and using hand tools, you walk behind or ride on a power trowel.

The result? A harder, flatter, more durable slab. This method boosts strength and appearance. It also helps prevent cracks and surface dusting. For a clear understanding, we can compare the hand and power trowel as:

Power Trowel vs. Hand Trowel

Hand troweling is fine for small jobs. But it’s slow and physically draining.

Power troweling speeds up the work and delivers better consistency.

Benefits of Power Troweling

Power troweling is a preferable method because it:

- Saves time

- Improves surface strength

- Reduces shrinkage cracks

- Provides a polished, professional look

Power Trowel Types: Which One Do You Need

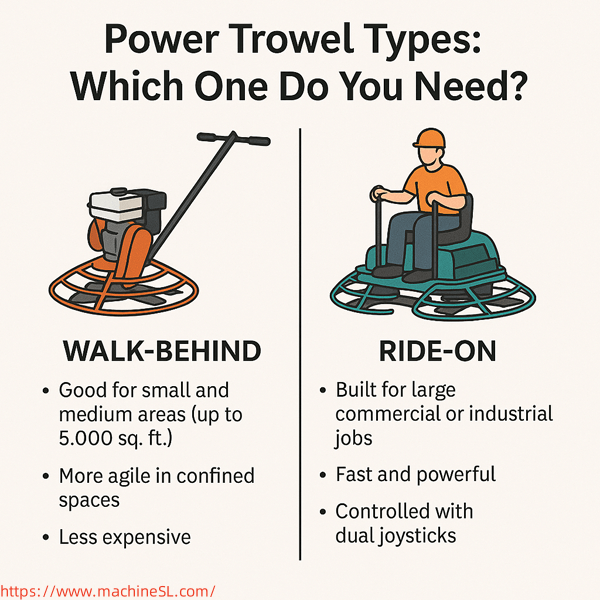

Before choosing the right power trowel, we will first describe the different types. Power trowel comes in two types as below:

Walk-Behind

As from name suggests, it is a machine which needs to walk behind for working. This machine is good for small and medium areas (up to 5,000 sq. ft.).

It is more agile in confined spaces and less expensive to obtain. Hence, it’s great for those who are building homes or starting with excavators for the first time.

Ride-On Power Trowels

Ride-on power trowels need a driver same like a car. They are built for large commercial or industrial jobs. It is Fast, efficient, and powerful. These can be used for parking areas, garages and large floors, etc.

These trowels can cover large areas in less time. Ride-on power trowels are controlled with dual joysticks or levers

When to Power Trowel Concrete (Timing Matters)

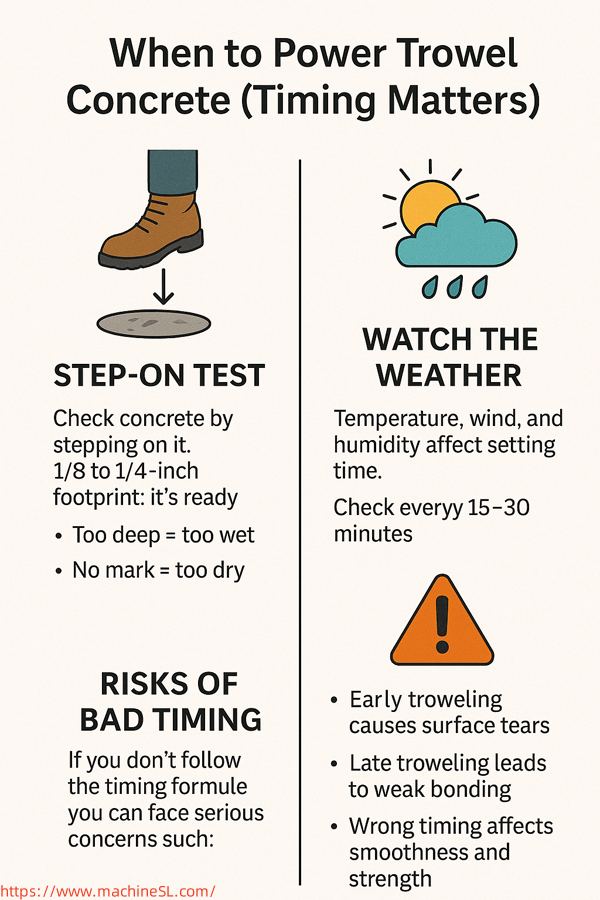

We have already explained the suitable equipment for trowelling. Let us decide when we should power trowel the concrete.

Troweling too soon or too late can ruin your slab. Here’s how to get the timing right:

Step-On Test

First, check the concrete by walking gently on the concrete. If your shoe leaves a 1/8 to 1/4-inch footprint, it’s ready. Furthermore, remember the rule

Too deep = too wet.

No mark = too dry

Watch the Weather

Temperature, wind, and humidity affect setting time. On hot days, concrete sets faster. On cold or windy days, it may take longer. Check the surface every 15–30 minutes.

Risks of Bad Timing

If you don’t follow the timing formulae, you can face serious concerns such as:

- Early troweling causes surface tears

- Late troweling leads to weak bonding

- Wrong timing affects smoothness and strength

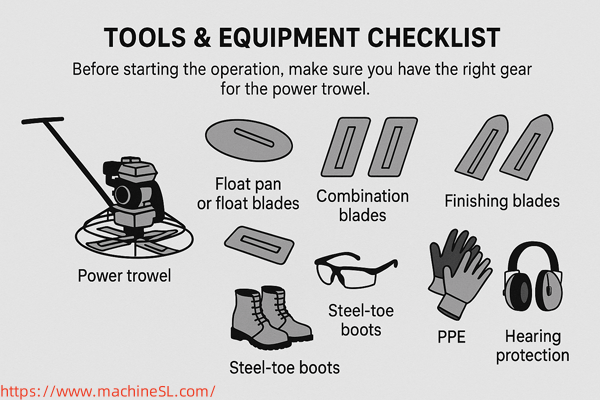

Tools & Equipment Checklist

Before starting the operation, make sure you have the right gear for the power trowel. Always inspect the trowel before starting.

Check engine oil, belts, and blade wear. Some of the important tools are:

- Power trowel: It may be of any type according to your project requirement. You can use either walk-behind or ride-on.

- Float pan or float blades: It can be chosen accordingly. It is required for the first pass.

- Combination blades: There are numerous types of blades available with the power trowel. For the multi-use option, you can use a combination of blades.

- Finishing blades: These are essential for the final pass.

- PPEs: It includes gloves, safety glasses, steel-toe boots, and hearing protection

How to Use a Power Trowel on Concrete (Step-by-Step)

This article is all about power troweling, and now we will guide you on “how to use a power trowel on concrete.”

However, it is a simple process, but it needs to be performed carefully. Follow the steps below to achieve the best results.

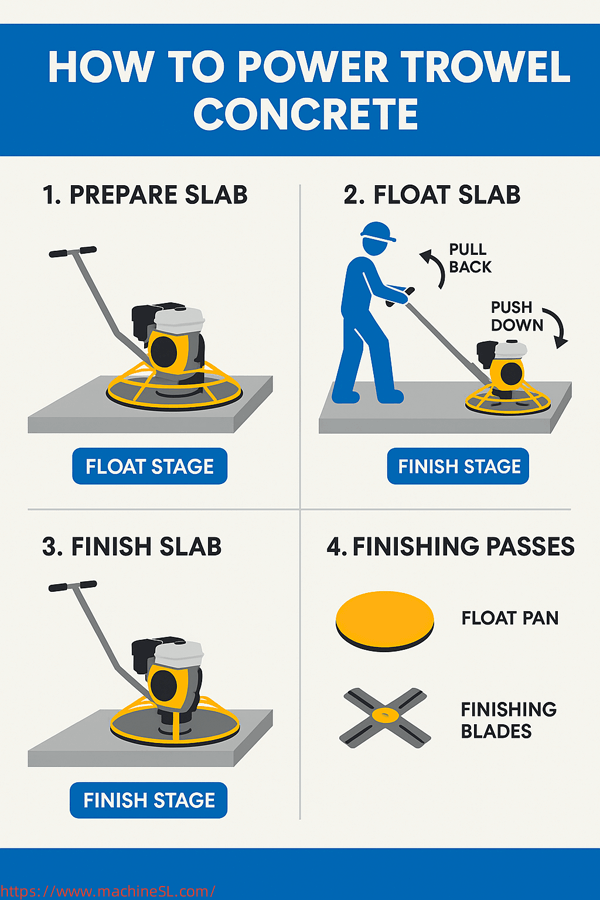

Step 1 – Prepare the Slab

Wait for the correct firmness using the step-on test. Remove debris, rocks, or marks from the surface.

Then you should make sure the concrete is level. Mark the slab edges or obstacles if visibility is low

Step 2 – Floating Pass

Attach float pan or float blades. Start the trowel at low speed. Apply steady downward pressure and walk backwards on your first pass.

Overlap each pass by 1/3 to 1/2. Then go over the area again at 90 degrees. This evens out the surface and removes air pockets

Step 3 – Switch to Finishing Blades

Wait until the slab can hold your full weight. Remove the float pan or blades. Attach finishing blades or combo blades.

Make a slow pass with flat blades. Gradually increase the blade pitch for each pass and finish until the surface is hard and shiny.

Blade Options and Configurations

There are several blades that can be used with a power trowel. Choosing the right blade makes a big difference. Here’s what each one does:

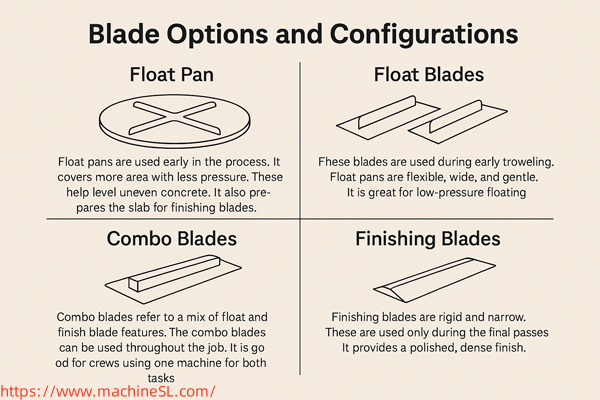

Float Pan

Float pans are used early in the process. It covers more area with less pressure. These help level uneven concrete. It also prepares the slab for finishing blades.

Float Blades

These blades are used during early troweling. Float pans are flexible, wide, and gentle. It is great for low-pressure floating

Combo Blades

Combo blades refer to a mix of float and finish blade features. The combo blades can be used throughout the job. It is good for crews using one machine for both tasks

Finishing Blades

Finishing blades are rigid and narrow. These are used only during the final passes. It provides a polished, dense finish.

Advanced Techniques for a Perfect Finish

Power trowelling is not only a process to get a smooth and even finish. There is ample space for new and advanced techniques to get the perfect one. Some of the useful advancements are as below:

Blade Pitch Control

This technique involves controlling the pitch of the blade. You can start from a flat or with a 5-degree pitch. Then increase pitch gradually to densify the slab.

Keep in mind that you must not over-pitch early, as it can gouge the concrete.

Overlapping Passes

The next tip is to overlap each path by at least half or one-third. It will ensure a consistent finish and density. However, the missed areas during trowelling can show imperfections later on.

Trowel Pattern

Trowel pattern uses linear passes for speed. You can try perpendicular passes for even coverage. The circular patterns help in blending and finishing the edges.

Burnishing Techniques

One technique for power trowelling is burnishing. Burnishing gives a glossy, professional look. In this, you should lower the blade pitch on final passes. Reduce the RPMs to polish the surface.

Dealing with Surface Blemishes

For surface blemishes, use the cross-hatching method to hide marks. Then overlap edges to blend visible seams. In the end, fix small cracks before the final pass.

Operating Tips for Beginners

As we discussed the advanced techniques, here are some tips for the beginners too.

Walk-Behind Power Trowel

This tool is called a walk-behind power trowel. You must lift or push the handle to control where a walk-behind trowel will go. Walk slowly and avoid sharp turns. Try practising in an open space before trowelling concrete.

Ride-On Trowel

If you are using a ride-on trowel, use both joysticks for smooth control. Don’t press too hard, too early. Watch your coverage pattern. Make sure fuel and oil levels are checked before use.

Safety Guidelines

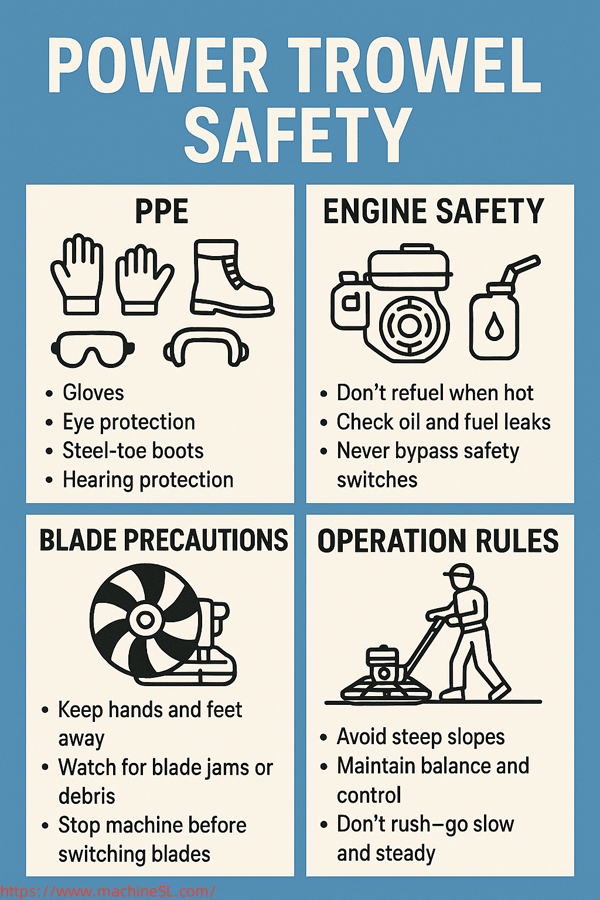

Safety measures are essential while operating any machine. The same is true with the power trowel. Power trowels are heavy and fast. One must take care while operating. He should have his PPE, which includes:

- Gloves

- Eye protection

- Steel-toe boots

- Hearing protection

Engine Safety

For power trowel engine safety, one must:

- Don’t refuel when hot

- Check oil and fuel leaks

- Never bypass safety switches

Blade Precautions

A power trowel possesses blades. They need to take some precautions. One should:

- Keep hands and feet away

- Watch for blade jams or debris

- Stop the machine before switching blades

Operation Rules

For safer operations, always keep the following operation rules in mind.

- Avoid steep slopes

- Maintain balance and control

- Don’t rush—go slow and steady

FAQs About Power Troweling

Q: How long should I wait before power troweling concrete?

A: Wait until you leave a light footprint (1/8–1/4 inch deep). This may take 1 to 4 hours after pouring.

Q: Can I power trowel in hot or windy weather?

A: Yes, but timing is critical. Hot and windy conditions dry the slab faster. Test the surface often.

Q: What’s the difference between burnishing and floating?

A: Floating is the first smoothing step. As a last step, for shining, we perform burnishing.

Q: Do I need to seal concrete after power troweling?

A: Sealing isn’t necessary, although it is considered helpful.. It adds protection and enhances appearance.

Q: Should I rent or buy a power trowel?

A: If you need it occasionally, the rental option is more feasible. For regular jobs, buying saves money over time.

Leave A Comment